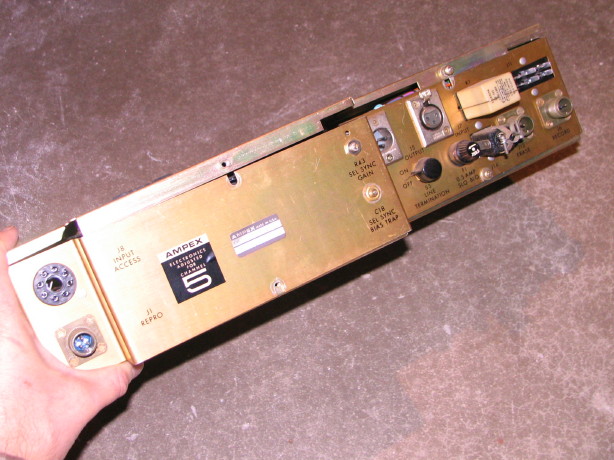

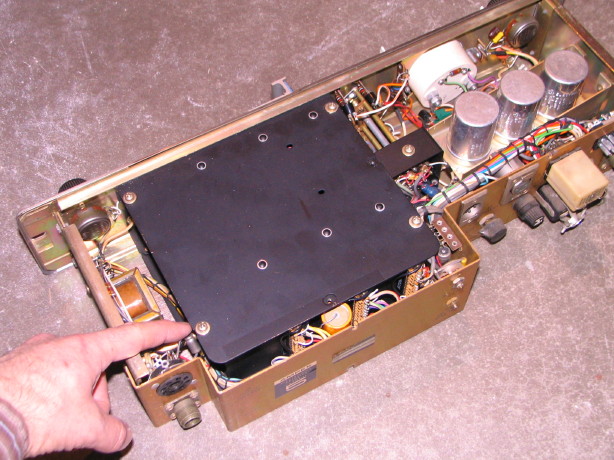

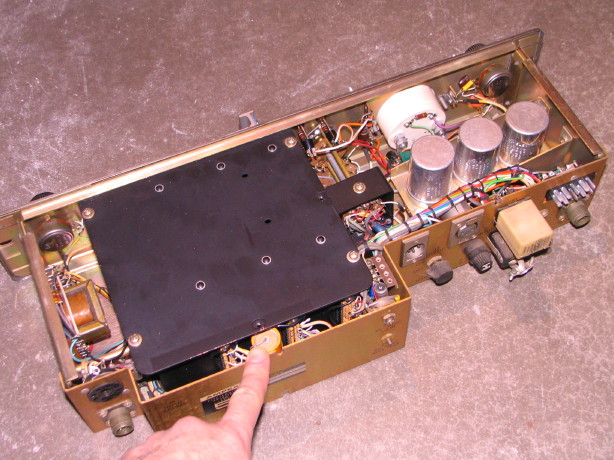

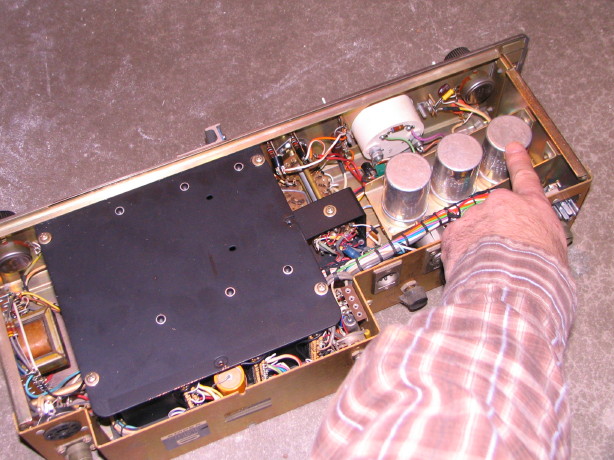

So I've been taking Technoplayer's suggestion and turning the machine on for hours at a time and just letting it run and you know what? The PLAY issue as well as the record arming issue for tracks 1, 3, 5 and 7 seems much improved. This is part of what I like about big old discrete electronics. Sometimes just working them works the bugs out. Not always the case of course, and naturally there are plenty of other pitfalls to "big old discrete electronics", but the MM-1000 does indeed seem to want to work.

Doing a little back-tracking with bearings.

There are several places on the MM-1000 that use "608" ball bearings. These are common "skateboard" or "inline skate" bearings with an 8mm ID, 22mm OD and 7mm thickness. I've been getting my bearings from vxb.com. Prices are good, quality seems very good for the price, and after my recent experience the service has gone from good to fantastic. They ship quick too.

Anyway, I got a pack of the

Kit657 from them a year or so ago to rebuild the reel motors in my 440-8, as well as the reel idler roller. One motor has been rebuilt...that's detailed in my 440-8 thread. Super smooth feeling after the rebuild, but granted there's a bit of mass there for damping and inertia, but really nice feeling...far sight better than the completely worn-out bearings that were in there. The reel idler was a vast improvement too but I could feel anomalies in the rotation...just some sort of random mechanical "noise". I figured that was as good as it needed to be and I wasn't going to spend more on more expensive bearings and it was such an improvement, again, over the worn bearings that were in there.

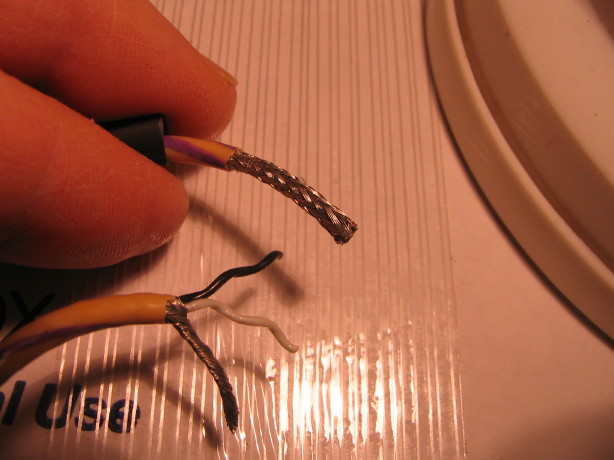

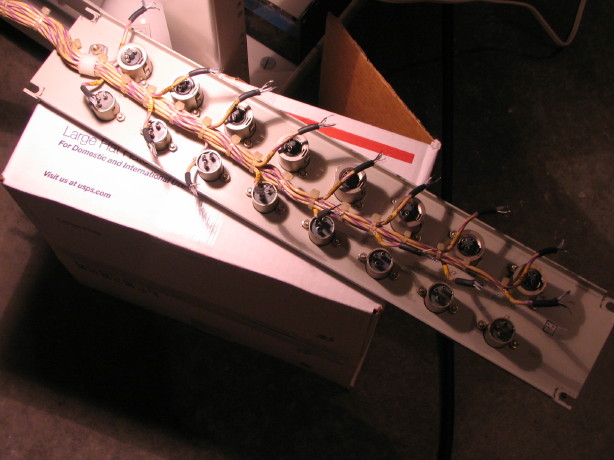

So zoom ahead to the MM-1000. I had 4 of the 8 bearings from that Kit657 left. The MM-1000 in stock trim uses the 608 bearings in 2 places: the reel idler roller (that's the roller with the viscous-damped flywheel), and the pinch roller. As detailed earlier in the thread I've done some rolling guide mods to the 1" tape path including using the "rotary guide" I stole from the parted-out 440-8. The rotary guide uses 608's also. So I rebuild that as well as the reel idler roller with those 4 608's and ordered two more of the same bearings to do the pinch roller. I wasn't happy with how the rotary guide felt...a higher degree of that random mechanical "noise" after mounting the bearings. The reel idler roller and pinch roller were better but still not as nice as I'd imagined. After getting the NOS 2" rolling guides out again and feeling how

rediculously smooth those are and after some research I started thinking...the pinch roller is important. It is right there after the playback head. Mechanical "noise" will be present in that section of tape if anything is imparting it and I wanted to minimize that. And the reel idler roller...that is a flutter damping device...an important one on the MM-1000 with so much unsupported tape, and with the viscous-damped flywheel it also reduces wow as well. An important part of the tape path. So again I want to minimize mechanical "noise" and in effect enable the assembly to do its job to the best of its abilities/design.

I contacted VXB to discuss my predicament...didn't want to spend $100 on a full-compliment full-ceramic bearing you know? Figured there HAD to be something of a happy medium on performance and price that would be at least as good as the stock bearings that came from the factory (which were nice bearings...Ampex was picky).

The other thing that is important here is that you can't just go get an ABEC-7 bearing and expect it is going to be top notch. The quality control on assembly as well as the quality of the ball cage, ball material, seal or shield construction/mounting...all these things play into the performance of the bearing despite the ABEC rating. PLUS...a bearing designed for

high RPM performance is not necessarily suited for low RPM performance. Who cares if the bearing is smooth at high RPM's but "noisy" at low RPM's? You want it smooth at low RPM's during PLAY modes. After batting terminology around and getting them to understand what I really needed and why I wasn't happy with the Kit657 bearings in certain applications they sent me up their "best 608's" to sample...I got them. They're the

Kit7809. Now, I figured these can't be the "best" they have...they are ABEC-5 and they are a hybrid (ceramic/steel). So I figure they are the best for my application. Out of the 8 in the package, 2 of them are unacceptable for the detail stuff. The other 6? Nice. If you think it seems wrong that 2 out of 8 aren't great or at least consistent with the others, I've seen it suggested by several that when ordering bearings it is best to order more than you need and hand-pick the best ones. I plan on letting vxb know about the 2 though. At any rate, I figured "okay these are the 'best' for my application" but then I saw the

Kit8347 and I though "hmm...those look the same but in an ABEC-

7 rating...why didn't they send

those?" So I asked and the response I got was this: "...the [Kit7809 bearings] have been made special to the specs that we like..They are an ABEC 5 but they are a non contact seals which is the balls do not touch the seal and the seal does not touch the side of the bearing. Which in return spin faster and longer." And I would assume more smoothly...maybe that's some of the mechanical "noise" I am feeling in the others.

At any rate, here is a video synopsis of this and a presentation of the dynamic differences in the Kit657 and Kit7809 bearings:

YouTube

So the head cover and pinch roller are already back off the machine...you'll understand why after watching the video.