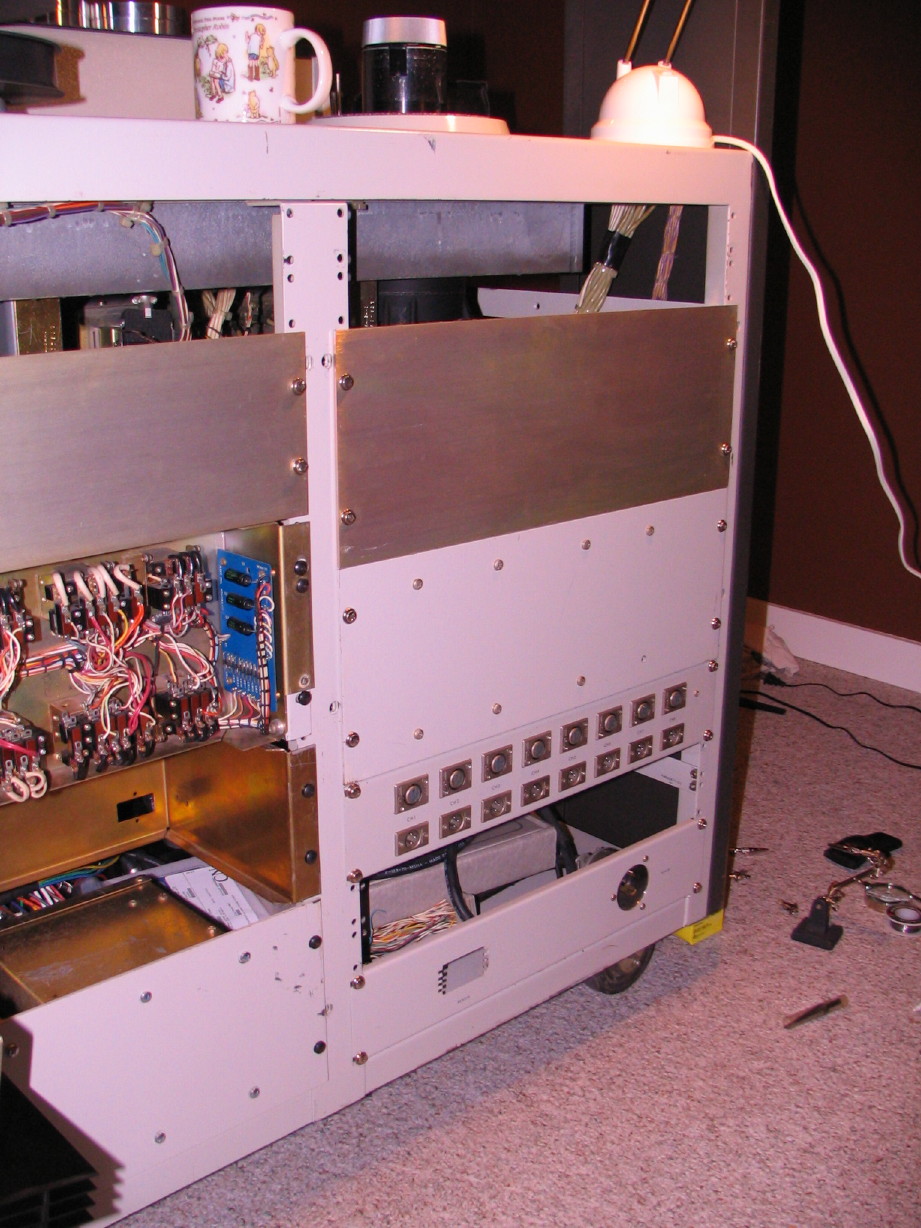

Rebuilding the 24VDC regulated supply. This is the unit that is located 2nd from the bottom on the left rack as you look at the back of the machine. Its sole purpose is to power the 24V devices in the transport. It does not directly power anything in the audio path.

There are 3 electrolytic capacitors (a 22,000uF/50V, 1,000uF/50V and a 50uF/6V). I have a hunch that the 22,000uF cap is fine but I have a replacement Mallory computer-grade cap to put in there that will fit right into the stock clamp. BTW this supply scoped clean when I tested it shortly after getting the MM-1000. The 50uF is probably fine too but I have a Sprague Atom series cap in 50uF/25V flavor so I'll put that in. The 1,000uF cap is the one I'm most interested in replacing as it is of the paper-board type exterior which I'm told are to be treated suspiciously after this many years. Again, I'm not having problems per se with the transport *except* for the intermittent PLAY issue. I'm pretty sure I'll find the problem in the relay box but I figure it doesn't hurt to have the PSU in relatively tip-top shape first anyway. I have a Nichicon PW cap for the 1,000uF cap but I'm shifting course on that...nothing against the Nichicon cap, but I'm going to go ahead and spend the $7~8 to get another of the Mallory computer-grade caps for that one. I believe that will be closer to stock spec and the original cap is a flange-type mount (attaches to the chassis with two screws) and the Mallory cap is the same diameter as the 2,400uF/80V Mallory units I put in the 39VDC regulated supplies and therefore uses the same separately purchased mounting clamp WHICH lines up with the same screw holes. Slick. There is also a diode on the little PCB I'm going to replace. I was also going to replace the rectifier diodes but once I dismounted the component chassis from the frame I noticed what I should have noticed from the schematic...it is a bridge rectifier unit rather than 4 discrete diodes. Well shoot. The schematic lists it as an Electron Devices

PB-10 or Motorola MDA 962-2. Had to search for awhile but finally found

this cross-reference guide which lists the Motorola MDA 962 series on it. Ahhhhhhhh-HA! 100V/10A. Mouser has some nice Vishay units and frankly its not much if any price difference so I'm going to get a 400V/25A unit. Overkill? Fine. Doing it anyway. So I'll have to wait a bit for the 1,000uF cap and the bridge rectifier to get here but in the meantime enjoy some pictures.

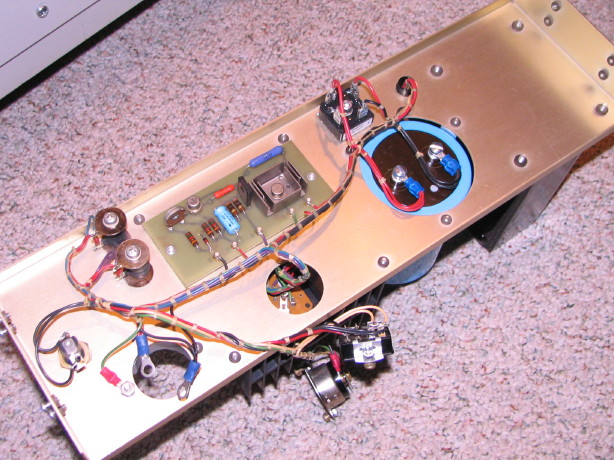

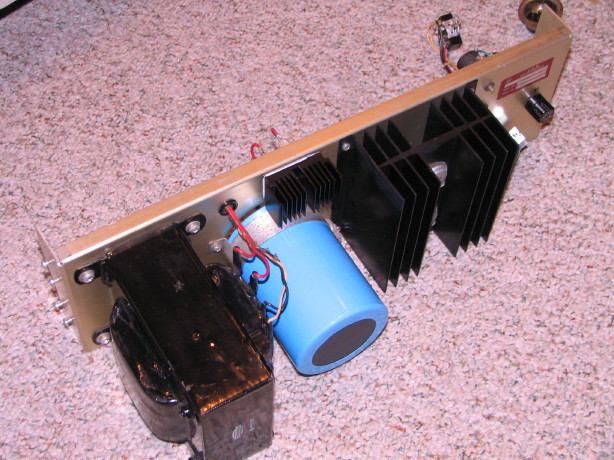

Here is the component frame separated from the mounting chassis...you can see the main transformer at the "bottom" (the big black chunk), then the 22,000uF main filter cap, and the power transistor heatsink above that and then the 1,000uF cap:

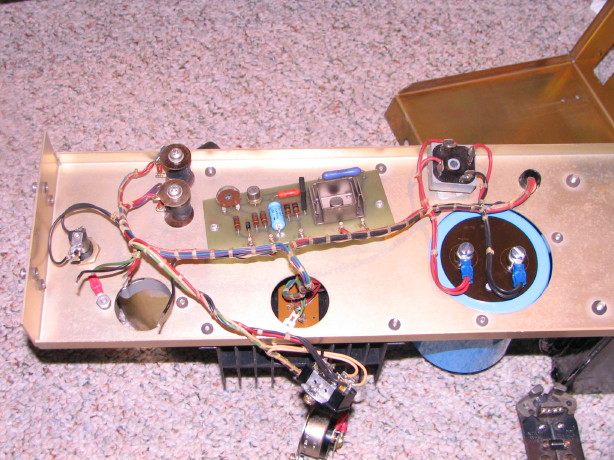

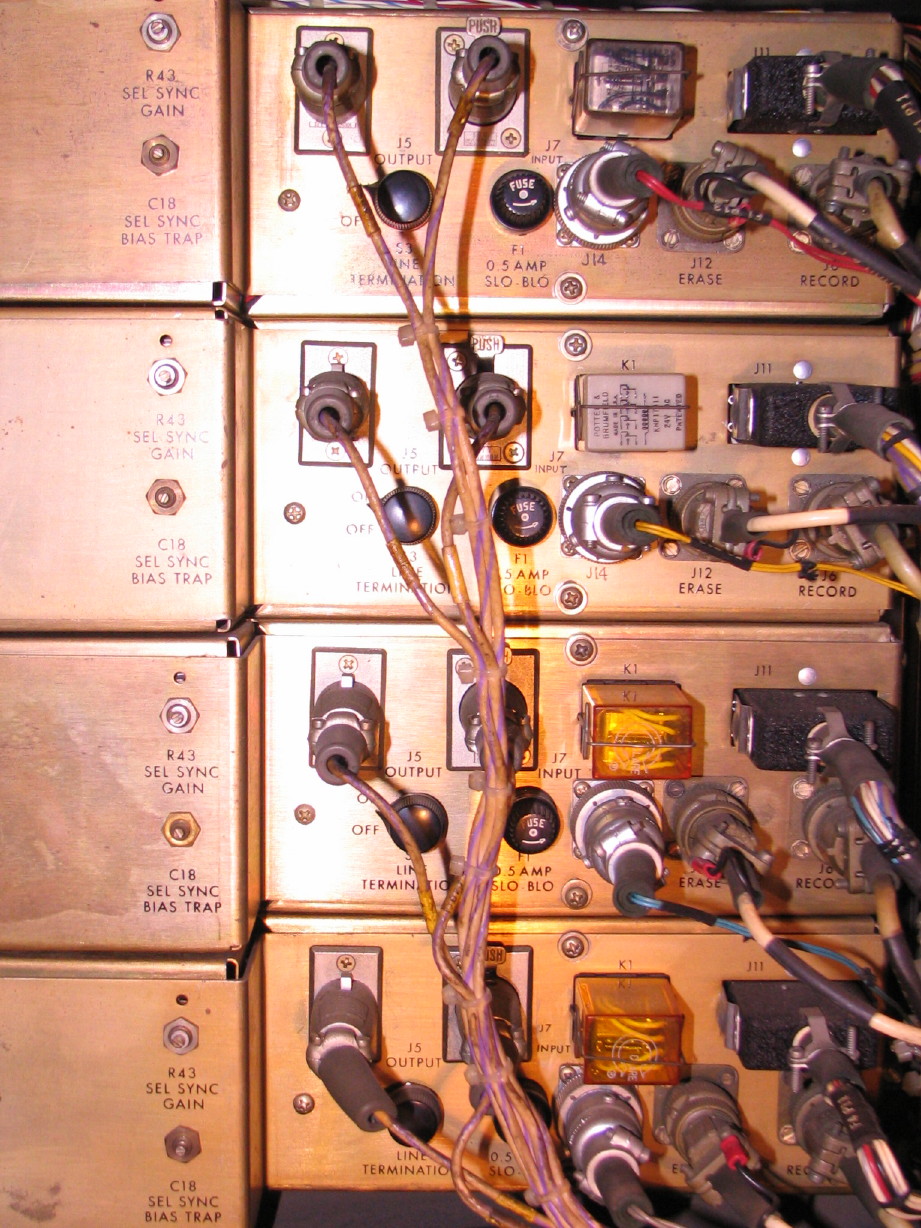

Then here is the "back" of the component frame with the other guts...and my surprise guest Mr. B Ridge Rectifier (located at the end of my index finger):

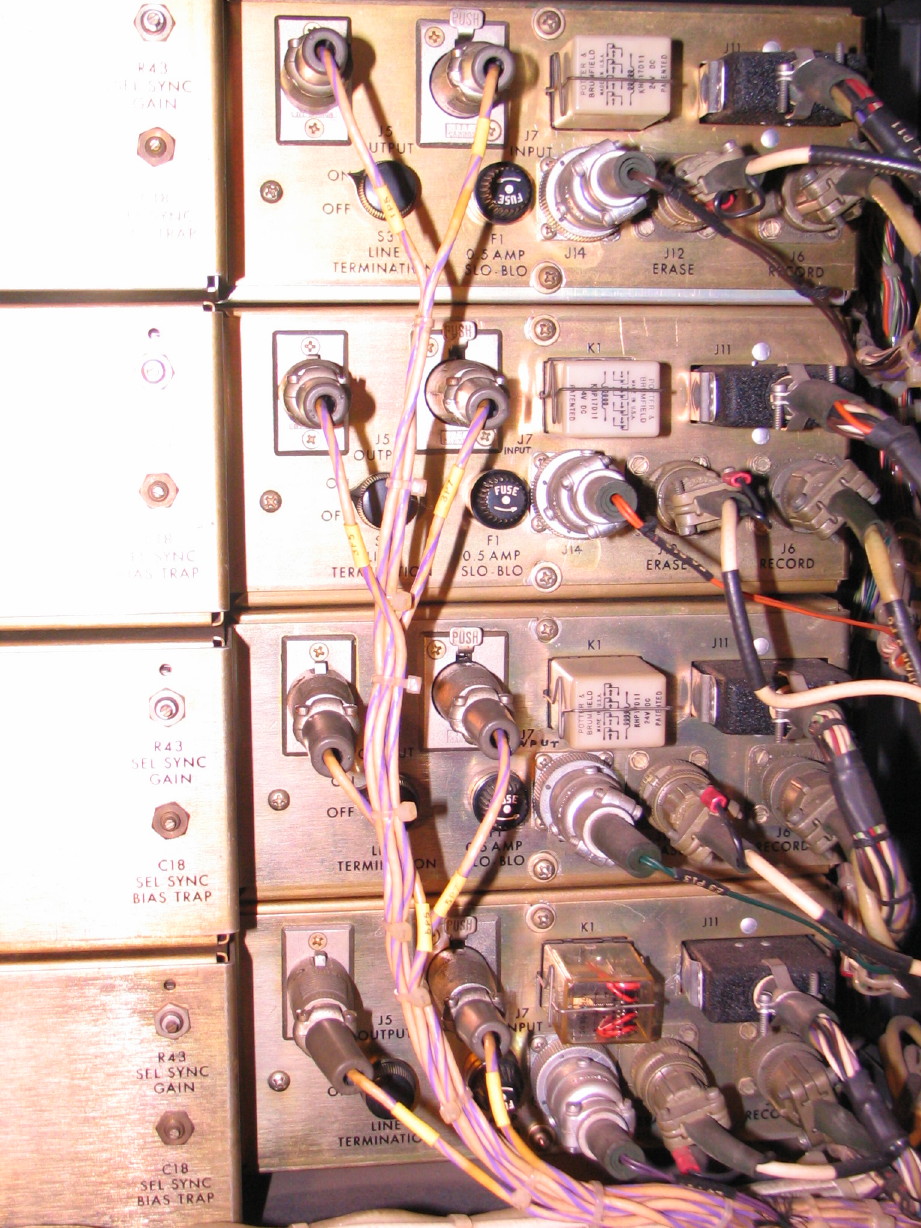

One last shot for now, 22,000uF and 1,000uF caps removed, PCB unmounted to desolder the one diode and the 50uF cap, and rectifier ready to have wires snipped and new one installed (when I get it):

Makes sense...and pardon my grammar in that post. Egads!

Makes sense...and pardon my grammar in that post. Egads!