sweetbeats

Reel deep thoughts...

So this is a story about the third Tascam 238 I’ve owned. The title of the thread references “Story #2”, because I already have a “Tascam 238 Story…” thread, but the 238 in this thread is actually the third 238 I’ve owned…I sort of skipped over the first one because it was short-lived in the stable, acquired for a specific purpose.

That first 238 was purchased basically to test a theory. I had just finished engineering and producing a second full length project using a computer-based DAW setup…this was late 2006…the DAW setup worked really well, and by that point I was really comfortable using it…even enjoyed using it to a point…but I always felt I had to work hard to get good sounds and so it often felt laborious to record, and I was also hopelessly caught in the trap of trying to make things loud which really sucked the life out of the music, at least with the tools and skills I had at the time. So I want everybody to understand it’s more likely my digital gear and skill set that spurred my frustration than anything else…but what I knew at the time about how analog audio tape media and digital audio media captured signal led me to want to see if, at that point, with all the experience using the DAW, analog tape might possibly ease some of my frustration.

I grew up in the 70s and was around analog stuff long before digital. I believe I dive into some of that background elsewhere on this forum, so I’ll spare repeating it here. But there were lots of cassettes…still are…and open-reel experience too. And the first recording project I was a part of as a band member was tracked to analog. And my own first multitrack machine was a Teac 3340S. So after all the intervening years in the digital domain I just wanted to see if analog recording intrinsically addressed frustrations I was having with digital gear and workflow. So I bought that first 238, which was cheap back then…$75 or something like that? I figured it might not be a perfect specimen, but work well enough to test my theory.

I was right on both counts…it was not a perfect specimen…Track 8 had diminished signal…lots of dropping in and out…but I was also right the sound was easily much warmer than my digital rig…it was warmer and more forgiving. Is that just because of a more constrained bandwidth and higher distortion? Maybe. But really truly that didn’t matter to me because it was a treat to use sonically compared to the DAW in an off-the-cuff way. And anyway it was kind of fun too because 15 or so years earlier I used to drool over the 238 in the AMS and Interstate Music Supply mailer. So it was a novelty to have one in front of me. I remember being impressed with how the transport handled the cassette, the metering…and everything there in that one 3U package…8 tracks and dbx noise reduction…it was just…refreshing I guess.

Most the time when I’m testing a recorder I just throw down something using bass because it’s handy…print any effects during tracking which is usually some sort of delay effect….here is the 8-track test sketch I recorded to that first 238:

https://www.torridheatstudios.com/Audio/Personal Music Sampler/Tascam 238 Test 2006 10 30 (16 bit master).wav

Listening back on it I can hear the drop-outs, and I’m pretty sure I was over saturating the tape or maybe levels were too hot and the dbx was mis-tracking. So the recording has issues but there were so many facets I liked about the character of how the analog media captured the sound…and it bears mentioning, and I don’t know if this is contradictory or whatever, but the front-end was my Yamaha 01X I had at the time…so…a digital mixer…and digital effects. So the bass was preamplified by the onboard instrument preamp on the 01X, converted to digital, and an AUX buss used to send to one of the onboard effect engines. The return was internally summed to the dry signal, converted back to analog and an analog output was used to connect to tape inputs as I built the sketch. And all the while I used the 01X as a cue mixer during overdubs. Thinking back I think I actually did a combination of printing dry and printing wet, and applied some additional effects at mixdown, which was all accomplished by the 01X. I was never dissatisfied by the sound of the 01X itself. I think my frustrations and dissatisfactions were really related to the engineering and post-production processes in the box…something always seemed lost in the sound once it got in there, and additionally bells and whistles are really not a good thing for me. So the argument could be made that the reason I liked the sound of the sketch was not the 238, but the digital pathway and effects of the 01X. But I would refute that argument, because I’d done tons of mixing and monitoring with the 01X by that point, only using the computer-based DAW as my multitracker. Using the 238 was, again, so refreshing and much more easily lush to my ears in spite of the deficits particularly with that first machine, and the limitations of the format. But I just didn’t care. It was so much easier to get a sound I liked. Maybe I was just that thirsty. But it was easy to determine from the test I wanted to incorporate an analog multitracker to the recording rig, but not cassette. That test led me to bring home a minty pair of 1/2” 8-tracks, a 48-OB and a 58-OB…$250 total for the pair with manuals…oh how times have changed. Those machines and my stories with them are documented elsewhere here on this forum, as well as many other escapades with many other machines…back to the 238…

So I returned that first 238 because of the track 8 issue…it was listed as fully functional, returns accepted.

238 #2 came along a number of years later in September of 2014. I have a thread on that one here:

https://homerecording.com/bbs/threads/tascam-238-story.384207/

Advance apologies, as I’m re-reading that old thread, there’s some retelling of information in this new thread from that one. At least I’m consistent lol. IIRC I sold 238 #2 with the RC-88 for a reasonable price to somebody on this forum maybe sometime in 2017 or early 2018. I had decided at that point I just wasn’t likely to use cassette 8-track, had a baby on the way, needed space and money, etc., so off it went. I wasn’t thinking I’d end up with a 238 again, but when you come across one in this day and age for $50 WITH the RC-88, and it’s local, even with the presumption it needs work, you get it. Well, maybe not everybody does. But I do.

Which finally brings us to 2022, and 238 #3. The story starts in this thread here in post #15:

https://homerecording.com/bbs/threads/what-is-it-that-compells-me….415149/#post-4670973

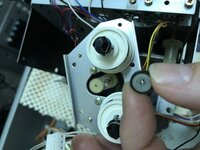

We leave that thread with 238 #3 running and driving, replete with a new capstan servo PCB installed, cleaned up, everything working except one of the edge tracks performing a little flakily, which has kind of been par for the course in my experience with cassette 8-tracks. And then it sat in various corners for months while we moved, and did various many other things.

To be continued…

That first 238 was purchased basically to test a theory. I had just finished engineering and producing a second full length project using a computer-based DAW setup…this was late 2006…the DAW setup worked really well, and by that point I was really comfortable using it…even enjoyed using it to a point…but I always felt I had to work hard to get good sounds and so it often felt laborious to record, and I was also hopelessly caught in the trap of trying to make things loud which really sucked the life out of the music, at least with the tools and skills I had at the time. So I want everybody to understand it’s more likely my digital gear and skill set that spurred my frustration than anything else…but what I knew at the time about how analog audio tape media and digital audio media captured signal led me to want to see if, at that point, with all the experience using the DAW, analog tape might possibly ease some of my frustration.

I grew up in the 70s and was around analog stuff long before digital. I believe I dive into some of that background elsewhere on this forum, so I’ll spare repeating it here. But there were lots of cassettes…still are…and open-reel experience too. And the first recording project I was a part of as a band member was tracked to analog. And my own first multitrack machine was a Teac 3340S. So after all the intervening years in the digital domain I just wanted to see if analog recording intrinsically addressed frustrations I was having with digital gear and workflow. So I bought that first 238, which was cheap back then…$75 or something like that? I figured it might not be a perfect specimen, but work well enough to test my theory.

I was right on both counts…it was not a perfect specimen…Track 8 had diminished signal…lots of dropping in and out…but I was also right the sound was easily much warmer than my digital rig…it was warmer and more forgiving. Is that just because of a more constrained bandwidth and higher distortion? Maybe. But really truly that didn’t matter to me because it was a treat to use sonically compared to the DAW in an off-the-cuff way. And anyway it was kind of fun too because 15 or so years earlier I used to drool over the 238 in the AMS and Interstate Music Supply mailer. So it was a novelty to have one in front of me. I remember being impressed with how the transport handled the cassette, the metering…and everything there in that one 3U package…8 tracks and dbx noise reduction…it was just…refreshing I guess.

Most the time when I’m testing a recorder I just throw down something using bass because it’s handy…print any effects during tracking which is usually some sort of delay effect….here is the 8-track test sketch I recorded to that first 238:

https://www.torridheatstudios.com/Audio/Personal Music Sampler/Tascam 238 Test 2006 10 30 (16 bit master).wav

Listening back on it I can hear the drop-outs, and I’m pretty sure I was over saturating the tape or maybe levels were too hot and the dbx was mis-tracking. So the recording has issues but there were so many facets I liked about the character of how the analog media captured the sound…and it bears mentioning, and I don’t know if this is contradictory or whatever, but the front-end was my Yamaha 01X I had at the time…so…a digital mixer…and digital effects. So the bass was preamplified by the onboard instrument preamp on the 01X, converted to digital, and an AUX buss used to send to one of the onboard effect engines. The return was internally summed to the dry signal, converted back to analog and an analog output was used to connect to tape inputs as I built the sketch. And all the while I used the 01X as a cue mixer during overdubs. Thinking back I think I actually did a combination of printing dry and printing wet, and applied some additional effects at mixdown, which was all accomplished by the 01X. I was never dissatisfied by the sound of the 01X itself. I think my frustrations and dissatisfactions were really related to the engineering and post-production processes in the box…something always seemed lost in the sound once it got in there, and additionally bells and whistles are really not a good thing for me. So the argument could be made that the reason I liked the sound of the sketch was not the 238, but the digital pathway and effects of the 01X. But I would refute that argument, because I’d done tons of mixing and monitoring with the 01X by that point, only using the computer-based DAW as my multitracker. Using the 238 was, again, so refreshing and much more easily lush to my ears in spite of the deficits particularly with that first machine, and the limitations of the format. But I just didn’t care. It was so much easier to get a sound I liked. Maybe I was just that thirsty. But it was easy to determine from the test I wanted to incorporate an analog multitracker to the recording rig, but not cassette. That test led me to bring home a minty pair of 1/2” 8-tracks, a 48-OB and a 58-OB…$250 total for the pair with manuals…oh how times have changed. Those machines and my stories with them are documented elsewhere here on this forum, as well as many other escapades with many other machines…back to the 238…

So I returned that first 238 because of the track 8 issue…it was listed as fully functional, returns accepted.

238 #2 came along a number of years later in September of 2014. I have a thread on that one here:

https://homerecording.com/bbs/threads/tascam-238-story.384207/

Advance apologies, as I’m re-reading that old thread, there’s some retelling of information in this new thread from that one. At least I’m consistent lol. IIRC I sold 238 #2 with the RC-88 for a reasonable price to somebody on this forum maybe sometime in 2017 or early 2018. I had decided at that point I just wasn’t likely to use cassette 8-track, had a baby on the way, needed space and money, etc., so off it went. I wasn’t thinking I’d end up with a 238 again, but when you come across one in this day and age for $50 WITH the RC-88, and it’s local, even with the presumption it needs work, you get it. Well, maybe not everybody does. But I do.

Which finally brings us to 2022, and 238 #3. The story starts in this thread here in post #15:

https://homerecording.com/bbs/threads/what-is-it-that-compells-me….415149/#post-4670973

We leave that thread with 238 #3 running and driving, replete with a new capstan servo PCB installed, cleaned up, everything working except one of the edge tracks performing a little flakily, which has kind of been par for the course in my experience with cassette 8-tracks. And then it sat in various corners for months while we moved, and did various many other things.

To be continued…

Last edited: