I FINALLY rebuilt/upgraded the second 39V power supply...

But first, before I discuss the power supply some responses:

Really, really nice work Cory. It's amazing to see (and fully appreciate) the progress throughout the archived posts, especially since when you first brought Matilda home.

Yeah...I think out of all my marathon threads this will be my favorite to look back over in years to come. This project has been the epitome of having a machine find you, causing you to realize what it is that you really want and everything you really need in a multitrack tape machine. That statement is specific to me because obviously an MM-1000 isn't a perfect fit for everybody, but I do hope that it inspires folks to enjoy the machines they have or to revel in finding the right fit. Its partly about features but also much about the nature of the machine. Everybody remember that I said I wasn't going to go in deep? Can't help it. When you know it is "IT" there's no reason to wait, except I suppose to stop dragging other enthusiasts along in suspense.

And again, looking back at the first couple posts...I remember thinking when I went to pick up the MM-1000 I was on the fence...I was thinking it may just be something that I clean up, patch up the basics and flip it to another buyer for some profit and experience...just no way I was going to pass up the deal that was the acquisition of the MM-1000...but another part of me was like "hmmm...could this be it?" It took a VERY short amount of time to jump off that fence, even with all the unknowns at that point.

It's been great being able to share the excitement and interest that you and everybody else following this thread have about you restoring this amazing machine. It's been over a year now! I've been following since day one. You are so close man! I can only dream of being able to bring old gear back life as well as you do.

I think that this thing should be a sticky! I have never followed a thread on ANY forum as long as this one. It's just incredible to see all the "Wow!" moments, and all of the larger than life parts in this machine.

Well, man, that's just cool!

I truly appreciate the enthusiasm, and I'm truly glad you've enjoyed it. That is exactly why I take the time to put up the info. Too much neat-o stuff to keep to myself and its really enjoyable to be able to share it with others who get tickled by it too, so thanks for sharing that.

I'd be closer if Matilda wasn't still in the garage covered in plastic. Its just not clean enough or WARM enough out there at this time to solder up that I/O panel, though technically I could just direct connect the snake to the electronics, but I'm tired of patchwork setups...next time I run the machine I want to have it properly connected to a mixer in a proper space. Need to get 'er move into the new studio space. Mayyyyyyybe by the end of the month...dunno for sure. The new space is painted and I've trimmed out all the electrical. Carpet is really the only thing preventing moving stuff in and that is up in the air at the moment. We'll be reusing some carpet from another area in the house, and we'll make the switch when we are having carpet installed in a couple other rooms.

Hey...wow...I don't know what to say about this thread being a sticky...I wouldn't fight it, but I just don't know how this would qualify...I thought stickies were for generally applicable information...I'm just blogging my machine you know?

But, hey, I'll take encouragement wherever I can get it.

You're doing a GREAT job Cory, I look forward to seeing it roll tape! Servicing our MCI is hardly such a heroic effort and it's still a real PITA Can't imagine the work you're putting in, but I think your efforts will be worth it!

Sheesh I don't know Brian...what you've been going through getting the logic straightened out on your MCI? THAT'S heroism AFAIC...but then you've also got to know that I get itchy around IC logic issues.

You've been going at that awfully hard and I do think its great that you are putting the info up here because the MCI machines are under-represented on this forum and that's something that is great to shift whenever we can.

Can't wait to so YOUR machine roll tape!

I second it being a sticky. It's an EPIC of one man vs machine!

Heh...that would just be wierd to see this stuck up there at the top of the forum...

And man vs. machine? In the words of Steve Puntolillo at Sonicraft (who runs a bevy of Ampex machines vocationally) "Ampex machines want to work...they can have their problems like any other machine but they want to work". So its really man vs. patience and perseverance because the machine and I are on the same team.

So, thanks...those comments are all really nice pick-me-ups!

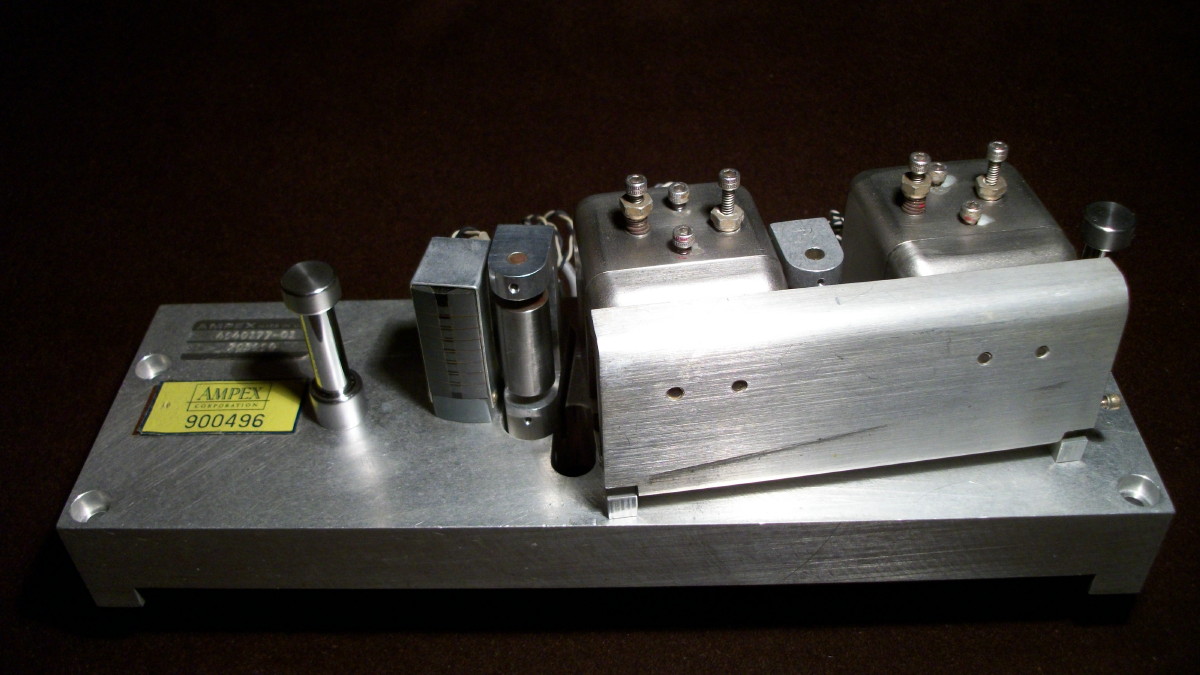

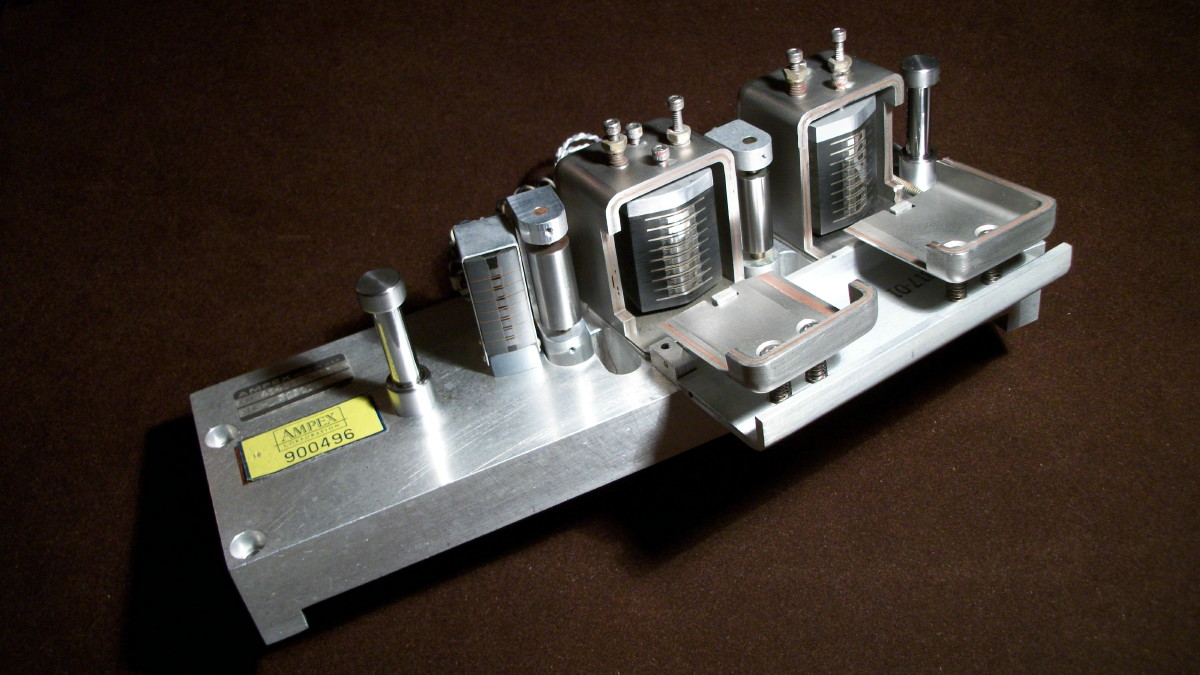

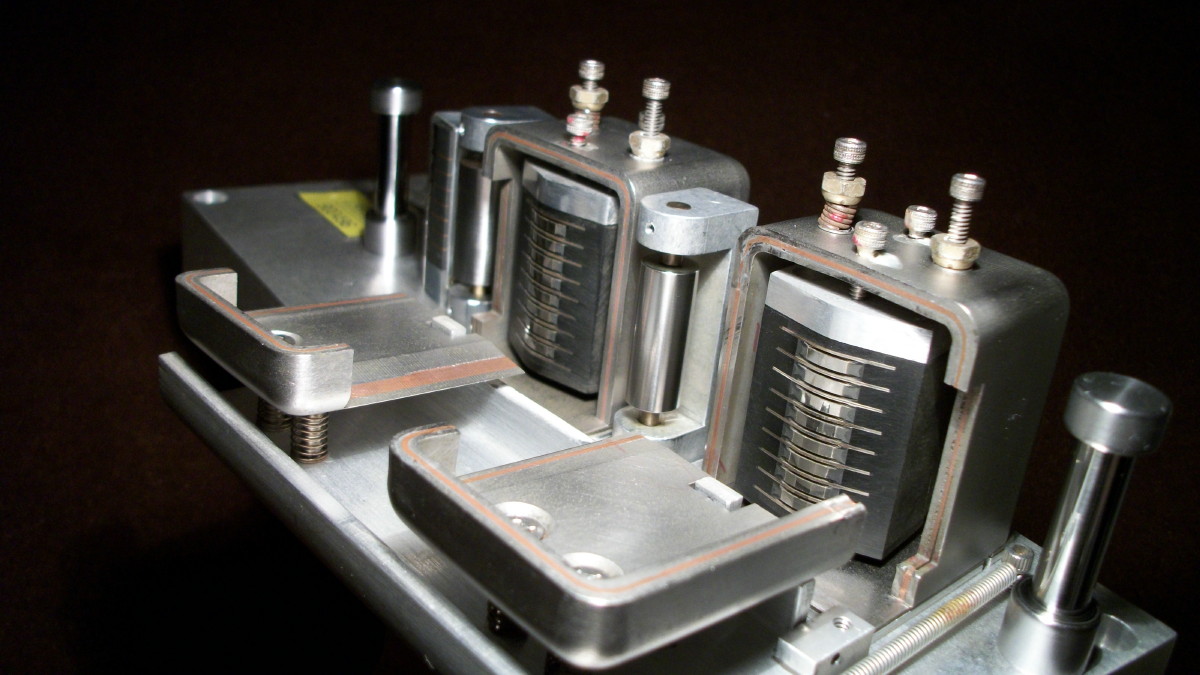

So look here at these two posts from my "Ampex 440B-8 Story..." They outline the procedure for rebuilding/upgrading the 39V regulated power supplies:

https://homerecording.com/bbs/showpost.php?p=3189317&postcount=95

https://homerecording.com/bbs/showpost.php?p=3191491&postcount=101

So if you noticed, those posts were from over a year ago, and in that time Matilda came along and the 440B-8 was parted out to provide funding and parts for the MM-1000 project. I'd done nothing with doing the work on the second 39V power supply because other matters took priority, and the 39V supplies on the MM-1000 scoped out really clean so I left well enough alone. Well, with the advent of having all the parts to convert Matilda to 2" 16-track operation I knew I'd want to start getting power supplies geared up. I have a total of 8 of the things (between the pair off the 440B-8, the pair that came in the MM-1000, a spare set that came with the MM-1000 and the units on the two 440 1/2"~1/2" machines I have). Matilda will need 4 of them in 2" trim. So I just thought "time to tie up that loose end." Before too long I'll order the parts needed to upgrade two more of them. BTW, the parts and procedure for the 39V power supply applies to the MM-1000 and all 440 machines. I'm happy to assist with part numbers and stuff if anybody else is thinking about doing this to one of their 440/MM-1000 39V supplies. Keep in mind that more often than not, even at over 40 years old, these power supplies tend to still operate clean and stable. Ampex did it right. What I'm doing with them is about 70% preventative and 30% potential gain in cleaner power (due to capacitor technology not available in 1969) and potentially better bandwidth specs (due to the new caps as well as the film bypass cap on C707, the main filter cap).

I still hold to everything I said in those posts linked above. It takes me about 3 hours to do the work on one supply. It IS slower work than swapping components out on a PCB, but it is oddly more satisfying work because of the challenge and the creativity that gets called out.

Also, just a little (440/MM-1000) 101: these 39V regulated power supplies supply power to the amplifier sections in the electronics modules in the applicable models. They each supply power to up to 4 modules (hence why the 16-track needs 4 of them). Like the electronics they are 100% discrete. +39V means the amplifier electronics have a voltage supply on tap that I believe exceeds the majority of audio supplies out there, most of which are +/-15V (for 30V total). You will also find +/-17V and +/-18V (for 34V and 36V respectively)...I know Presonus made a deal about their Digimax units operating on 35V (likely +/-17.x volt rails). FWIW

my Digimax FS is my favorite rackmount mic pre and intrument pre. The higher voltage tends to equate to higher headroom. As I've mentioned before the 440/MM-1000 amplifier electronics are rated to posess some relatively sick headroom...the record amp section is clean (i.e. <1% THD up to clipping which occurs at

"28dB above normal operating level."

The electronics operate at +4dBm or +8dBm...do the math...that means that the rated clipping point on the record amp is at +36dBm...and the reproduce amp can drive up to +28dBm before clipping. What that means is that the electronics can take a

spanking

before clipping. NO worries about the electronics clipping before the tape...and the higher voltage supply is part of that. My Soundtracs MX desk runs on +/-17V rails and has a rated headroom of 22dB's...does this mean everybody has to run out and find gear with high voltage rails?

HEAVENS NO!

Lots of stuff at play here, and the VAST majority of auio electronics operates on +/-15V rails. Its just been a progressive shift. Higher supply voltages mean physically bigger everything. Pick your battle.

Anyway, enjoy...enough for today.

Time to go to bed (that comment is for you Ethan...

).

Can't imagine the work you're putting in, but I think your efforts will be worth it!

Can't imagine the work you're putting in, but I think your efforts will be worth it!

I truly appreciate the enthusiasm, and I'm truly glad you've enjoyed it. That is exactly why I take the time to put up the info. Too much neat-o stuff to keep to myself and its really enjoyable to be able to share it with others who get tickled by it too, so thanks for sharing that.

I truly appreciate the enthusiasm, and I'm truly glad you've enjoyed it. That is exactly why I take the time to put up the info. Too much neat-o stuff to keep to myself and its really enjoyable to be able to share it with others who get tickled by it too, so thanks for sharing that. But, hey, I'll take encouragement wherever I can get it.

But, hey, I'll take encouragement wherever I can get it.

You've been going at that awfully hard and I do think its great that you are putting the info up here because the MCI machines are under-represented on this forum and that's something that is great to shift whenever we can.

You've been going at that awfully hard and I do think its great that you are putting the info up here because the MCI machines are under-represented on this forum and that's something that is great to shift whenever we can.

The electronics operate at +4dBm or +8dBm...do the math...that means that the rated clipping point on the record amp is at +36dBm...and the reproduce amp can drive up to +28dBm before clipping. What that means is that the electronics can take a spanking

The electronics operate at +4dBm or +8dBm...do the math...that means that the rated clipping point on the record amp is at +36dBm...and the reproduce amp can drive up to +28dBm before clipping. What that means is that the electronics can take a spanking  before clipping. NO worries about the electronics clipping before the tape...and the higher voltage supply is part of that. My Soundtracs MX desk runs on +/-17V rails and has a rated headroom of 22dB's...does this mean everybody has to run out and find gear with high voltage rails?

before clipping. NO worries about the electronics clipping before the tape...and the higher voltage supply is part of that. My Soundtracs MX desk runs on +/-17V rails and has a rated headroom of 22dB's...does this mean everybody has to run out and find gear with high voltage rails? ).

).