sweetbeats

Reel deep thoughts...

Couple quick updates...

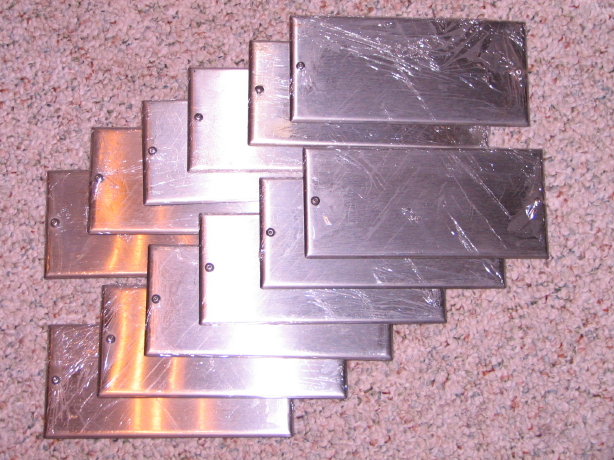

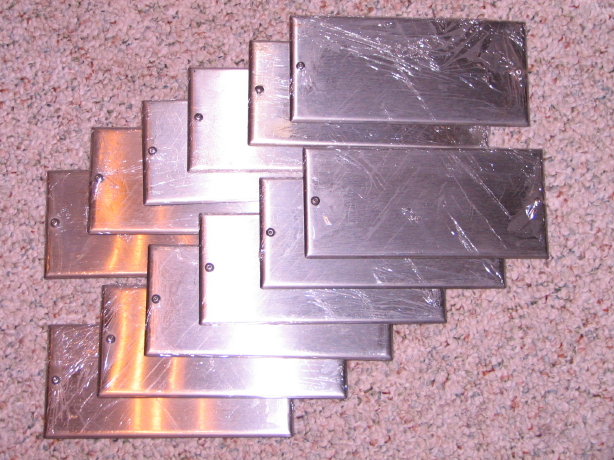

This is cool. You know how I had pretty much resigned myself to the fact that I wasn't going to have the stainless steel covers for the amplifier card bays? My MM-1000 came without them...not too uncommon for the 440/MM-1000 family as they ARE kind of in the way of amp card trimmers and so often operators would take them off and never put them back on...but I DO have a set from the 440-8 I parted out but some of those are pretty beat up and I was going to use a couple of the nicer ones for my 440C halftrack project anyway...so having less than half of them for the MM-1000 in 16-track trim and some of those being kind of trashed and what with the typical asking price for those covers when you can find them I figured "aw it looks pretty cool without them" and that was that...until an acquaintance of mine and fellow MM-1000 owner rediscovered a box of 42 of the things amidst his collection of spares and made me an offer I couldn't refuse that included S&H on 12 of them (I have enough good ones to make the count 16)...he even reglued the cork pads that are on the backside of the covers and polished them up...picked out "the best ones" for me...they all even have the original captive stainless button-head socket cap screws for fastening them to the electronics chassis. And he wrapped each one in pastic wrap, separated each one with a layer of closed-cell foam sheeting...wow. I was just totally impressed. I couldn't resist unwrapping 8 of them and mounting them to the electronics and you know what? They really do look kinda cool, and you know me...I just like having things be "complete" anyway.

Here's the set still wrapped up:

I've never seen so many in this good of shape all at once.

And here they are on the machine:

And I'm still waiting for bearings to arrive so I'm continuing on with dabbling in the 16-track conversion, the ugliest part of which will be installing the the main harness. Have to clean it up and inspect it first so I dug it out of storage and for the next while I'll pick away at scrubbing it up, cleaning all the connector contacts and opening up the Cinch Jones connector hoods and checking the condition of the solder joints and the female sockets.

I really think its a pretty solid assembly, just needs cleaning up, though there are a couple rogue wires I need to trace back and see what they are there for.

Here it is on the floor by the MM-1000 which is where I imagine it'll be for awhile:

Notice, for perspective sake, that the panel at the bottom of the picture is a 2U standard rack-width panel. Some wire there...

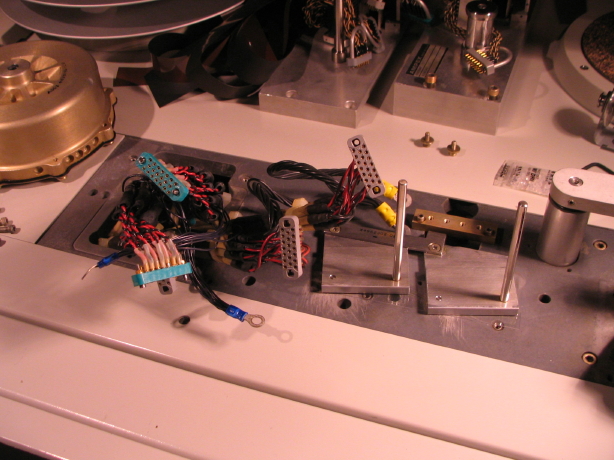

Okay, last thing for now is that I know how Ampex crammed another 8 channels of cabling into that head connector housing...looks like later transport plates have a slot cut out for the cables to pass through rather than the hole directly above the reel idler flywheel. Same guy that sold me the cardbay covers was kind enough to send me pics of his machine's innards and in the picture below you can see all those fat wire assemblies dropping straight down from the underside of the transport plate, and you can see the viscous reel idler flywheel toward the right. Well, the hole in my transport plate is right above the flywheel. In fact that flat metal plate is a deflector to keep the wires from dragging on the flywheel, but notice none of my friend's head cables drop down anywhere near that deflector. Why? Because his has a slot that goes most the way across to the lifter linkage hole. This makes it possible for the cables to drop down through the transport plate much closer to the head connectors which means less stuffing of the wires horizontally under the housing...they just go down and through. Funny thing is that I think his is a pretty early model, but mine must be earlier. And no I'm not going to try and drill additional holes in the 5/8" thick heat-treated steel plate.

This is cool. You know how I had pretty much resigned myself to the fact that I wasn't going to have the stainless steel covers for the amplifier card bays? My MM-1000 came without them...not too uncommon for the 440/MM-1000 family as they ARE kind of in the way of amp card trimmers and so often operators would take them off and never put them back on...but I DO have a set from the 440-8 I parted out but some of those are pretty beat up and I was going to use a couple of the nicer ones for my 440C halftrack project anyway...so having less than half of them for the MM-1000 in 16-track trim and some of those being kind of trashed and what with the typical asking price for those covers when you can find them I figured "aw it looks pretty cool without them" and that was that...until an acquaintance of mine and fellow MM-1000 owner rediscovered a box of 42 of the things amidst his collection of spares and made me an offer I couldn't refuse that included S&H on 12 of them (I have enough good ones to make the count 16)...he even reglued the cork pads that are on the backside of the covers and polished them up...picked out "the best ones" for me...they all even have the original captive stainless button-head socket cap screws for fastening them to the electronics chassis. And he wrapped each one in pastic wrap, separated each one with a layer of closed-cell foam sheeting...wow. I was just totally impressed. I couldn't resist unwrapping 8 of them and mounting them to the electronics and you know what? They really do look kinda cool, and you know me...I just like having things be "complete" anyway.

Here's the set still wrapped up:

I've never seen so many in this good of shape all at once.

And here they are on the machine:

And I'm still waiting for bearings to arrive so I'm continuing on with dabbling in the 16-track conversion, the ugliest part of which will be installing the the main harness. Have to clean it up and inspect it first so I dug it out of storage and for the next while I'll pick away at scrubbing it up, cleaning all the connector contacts and opening up the Cinch Jones connector hoods and checking the condition of the solder joints and the female sockets.

I really think its a pretty solid assembly, just needs cleaning up, though there are a couple rogue wires I need to trace back and see what they are there for.

Here it is on the floor by the MM-1000 which is where I imagine it'll be for awhile:

Notice, for perspective sake, that the panel at the bottom of the picture is a 2U standard rack-width panel. Some wire there...

Okay, last thing for now is that I know how Ampex crammed another 8 channels of cabling into that head connector housing...looks like later transport plates have a slot cut out for the cables to pass through rather than the hole directly above the reel idler flywheel. Same guy that sold me the cardbay covers was kind enough to send me pics of his machine's innards and in the picture below you can see all those fat wire assemblies dropping straight down from the underside of the transport plate, and you can see the viscous reel idler flywheel toward the right. Well, the hole in my transport plate is right above the flywheel. In fact that flat metal plate is a deflector to keep the wires from dragging on the flywheel, but notice none of my friend's head cables drop down anywhere near that deflector. Why? Because his has a slot that goes most the way across to the lifter linkage hole. This makes it possible for the cables to drop down through the transport plate much closer to the head connectors which means less stuffing of the wires horizontally under the housing...they just go down and through. Funny thing is that I think his is a pretty early model, but mine must be earlier. And no I'm not going to try and drill additional holes in the 5/8" thick heat-treated steel plate.

Attachments

Last edited:

They weren't that methodical. The AG-1000 was put out in a hurry, and suddenly Mirasound is using that machine pretty much around the clock for the next 3 years, and hits are coming out and the new rage is 16-tracks and then 24-tracks and studios are buying the MM-1000 in spite of its kludginess.

They weren't that methodical. The AG-1000 was put out in a hurry, and suddenly Mirasound is using that machine pretty much around the clock for the next 3 years, and hits are coming out and the new rage is 16-tracks and then 24-tracks and studios are buying the MM-1000 in spite of its kludginess.