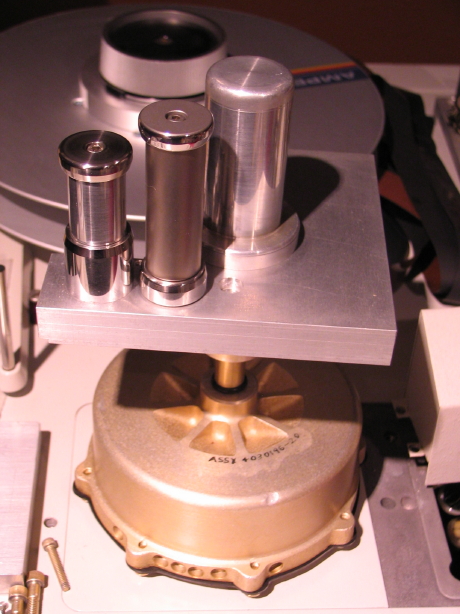

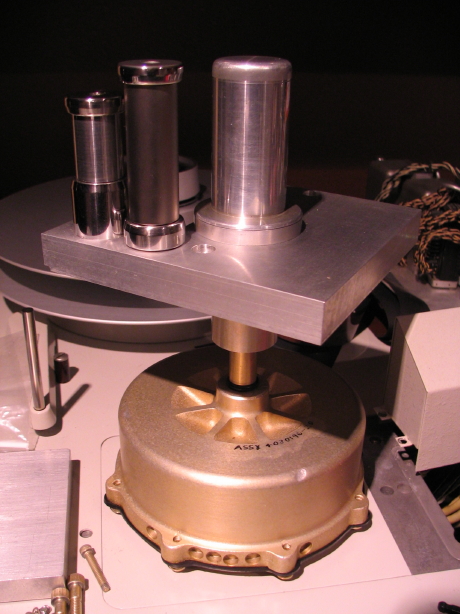

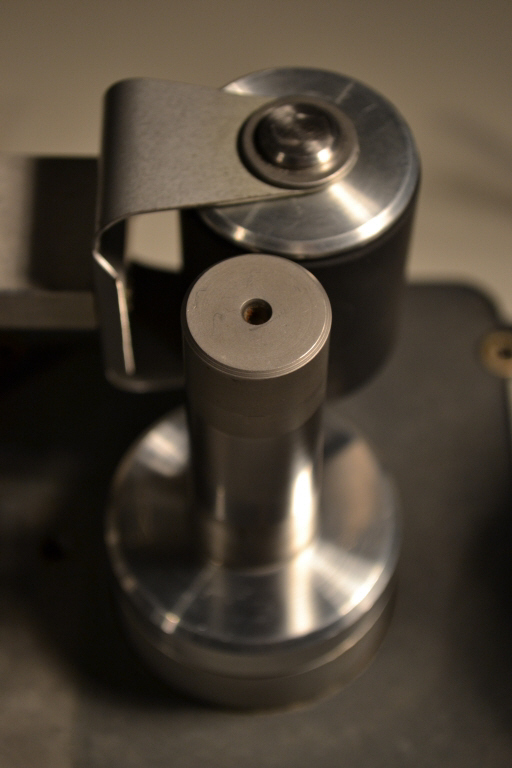

So at the moment I'm still in flux on the flywheel problem. I'm still not convinced it is leaking from the inside; that it may be fluid saturated in the pores of the aluminum housing. If it IS leaking from the inside then there is the question of whether it is because the wrong viscosity Dow Corning 200 fluid is in there, OR if it is because there is some damage to the housing. I continue to warm the assembly and fluid continues to sweat onto the surface. I reviewed dialog from a year ago when I was led to the determination that the proper fluid viscosity is the 200 centistoke fluid I put in there. If for some reason that determination is flawed and the viscosity is too low then I suppose it is possible that it is fluid enough to leach through the cast aluminum. OR maybe there is just enough fluid soaked into the aluminum from it leaking out in years past.

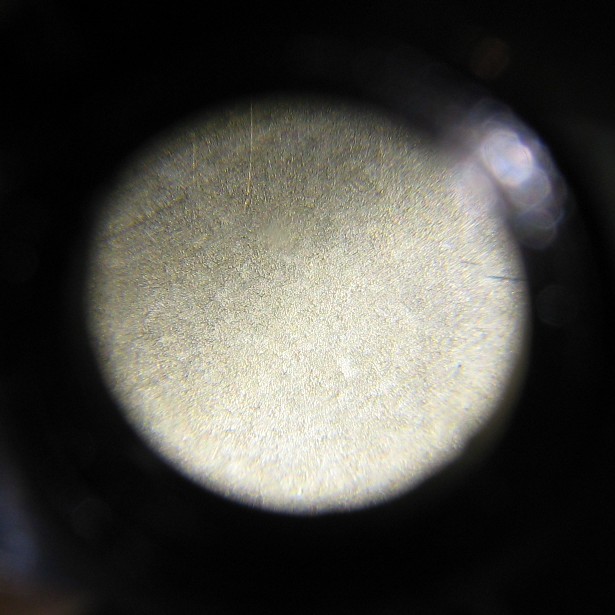

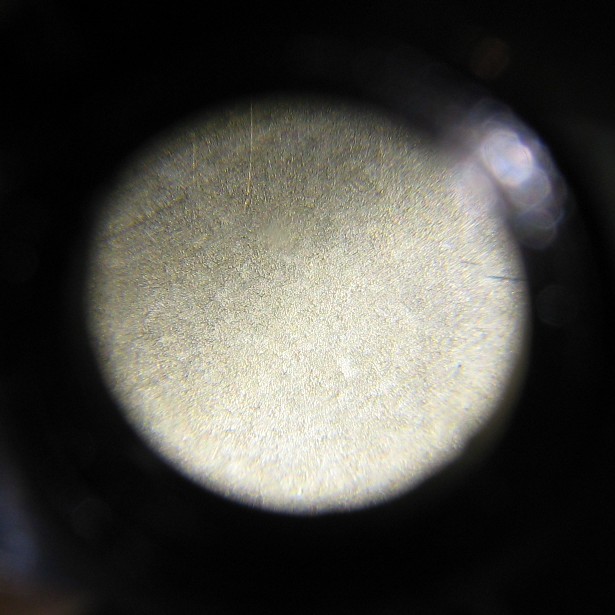

Reviewing my notes on trying to clean the stuff up from before I realize I've been through this frustration before, though this seems to be to a greater degree. I'm trying to get some mineral spirits again since that seemed to help. I've been using iso alcohol and acetone and tissue. Its crazy stuff. I've realized that those efforts are fruitless. You'd think you could use tissue to wipe up just about anything, but you know what? I don't think this fluid soaks into tissue at all, and I believe the solvents I've been using are useless. You can wipe and wipe and wipe and it can look clean and dry but I'll you've done is spread the stuff out and then it congregates over time...OR maybe it is leaking out as well. I just can't tell, but first step is to get some mineral spirits, and I've started using a scrap t-shirt to do the wiping, one where I can see the wetness of the fluid in the cloth so I know I am actually picking some of it up when I wipe. When I cease warming the flywheel in front of the heater it stays dry. So why am I concerned? Because it gets warm inside that machine. Warm it and the wet patches/spots of fluid come back though I *think* they are decreasing since I traded the t-shirt cloth for the tissue. I'll continue wiping and warming and add mineral spirits to the process when I can find some (the "low odor" mineral spirits aren't the ticket and that seems to be all I can find just yet). Here is a closeup of the surface of the flywheel under 10x magnification. You can see that it has quite a texture:

On to other bits...its not all quandry and query...

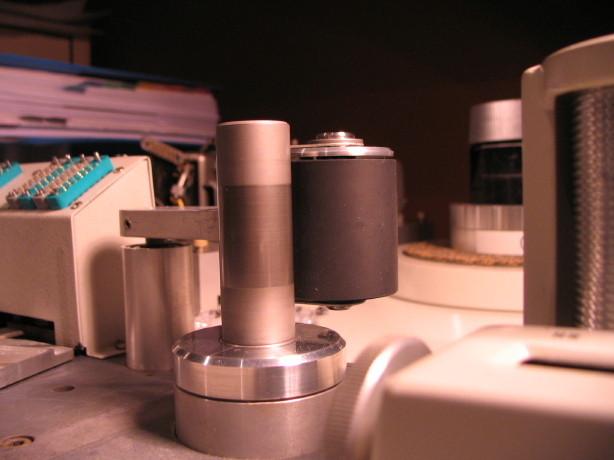

I've got the pinch roller setup 100% to my satisfaction.

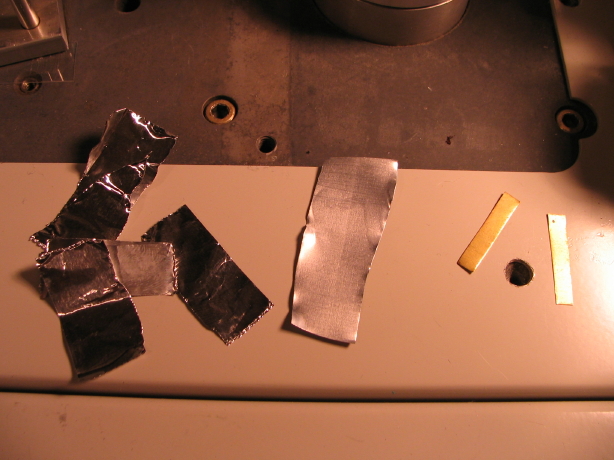

For some reason the yoke that holds the pinch roller measures 0.010" more from the shaft to the back of the yoke at the bottom of the yoke than at the top, okay? Can't imagine that is the way it is supposed to be. I thought I could use aluminum foil for shim stock to correct the discrepancy where the yoke mounts to the pinch roller arm. The foil is a little less than 0.001" thick. Well, I'd put three layers in between the yoke and the end of the pinch roller arm and that wasn't enough to correct the problem. I didn't like the idea of stacking more and more pieces of the foil. Then I found some 0.005" shim stock and tried that. Too much. I thought maybe some 0.003" shim stock would work but there isn't anywhere around here that carries such stuff so I started looking around the house. Guess what? Aluminum soda pop cans are made from 0.003" thick aluminum. So I made a shim out of a piece of a pop can.

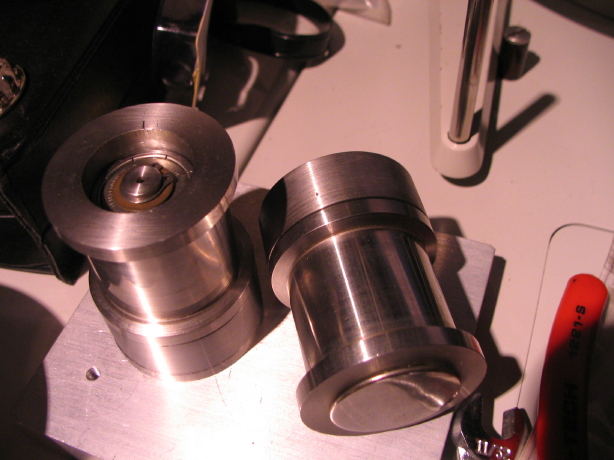

Here is a shot of my shim materials, from left to right the foil, pop can and 0.005" shim stock:

Here is a shot of the pinch roller arm with the roller and yoke assembly loose so you can see where the shim is to be placed:

And here is the yoke fastened to the arm with the shim in place:

Here is the before closeup of the roller in relation to the capstan shaft...you can see that it kicks out just a shade at the bottom:

And here is the after shot with the shim in place...looks good:

And here is the dynamic duo ready to pull tape:

I tested the runout of the pinch roller arm again with the dial indicator and it is totally incredible. I can't believe what Terry Witt can do with these rubber rollers...I'd say the surface of the pinch roller is correct to around 0.0002", maybe 0.0003" tops. Incredible.

Here is a YouTube video showing the dial indicator tests as well as an overview of the debacle and solution with the tilt of the pinch roller:

YouTube

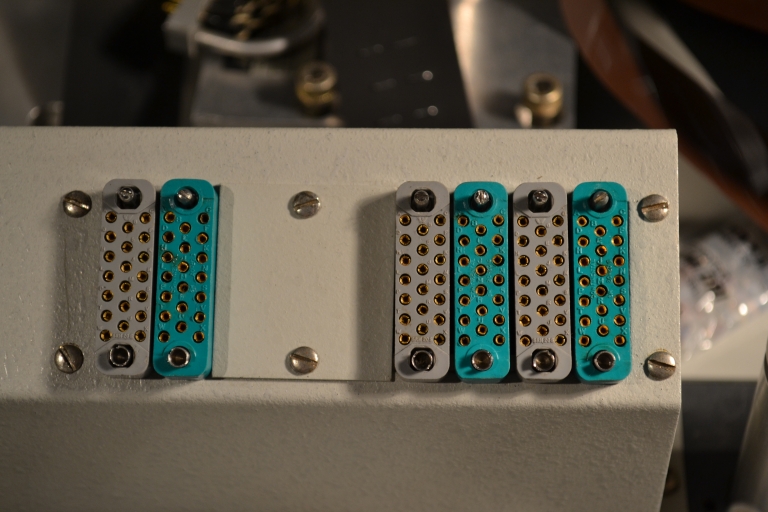

I'm still picking away at cleaning up the 16-track harness.

I also got ahold of another 1" rotary guide from a 440-8. I'm...not...sure...why. I originally thought I had an idea as to where to use it but...uh...not totally sure what I was thinking. So, I have another one. It was only $15 and it is better than the one I put on my MM-1000. $15 for a good condition precision 1" Ampex guide is good so....

ALSO...I completed the snake to interconnect the MM-1000 with my Soundtracs MX console. They are hooked up. I'm finishing up getting the console back together.

Just gotta get a grip on the whole reel idler flywheel issue because if it IS leaking I don't want to put it back in the machine until I get it fixed.

Here are some YouTube videos of the before and after:

Here are some YouTube videos of the before and after: