Let me see if I can bring some clarity to this latest wrinkle.

First off, some responses:

As I first read your report it struck me as a bit of a conflict of interest (dont take that wrong).

No not at all. I totally get what you are stating there...and just know that the owner and I have been dialoging for over a year, and after a long silence he let me know that he had put it up for sale and that he had a bite and the potential buyer was coming to look at it. I knee-jerked and said essentially "oh man I wish you would have talked to me first", so he's known there is some interest there, but the potential buyer backed out after looking at it and the owner contacted me and asked for my help in determining its worth/what it needs, etc. I have to operate with high degree of integrity and ethical prowess in my line of work so I'm used to being able manage conflicting situations. I offered to help him and both of us knew that there was potential income in it for me in providing service and I think both of us also knew that if he decided to ditch the machine I'd be close by figuratively speaking to consider it. No hiding, no mysteries...he's been great to work with and I was very clear with him that when I made the service call my goal was to help him get a grip on what it needs; ultimately to help him be able to plan for how to get it running and into use. I think my report was well balanced...clearly stated the positives of the machine along with bare minimums to get it going and also what would be needed to get it to spec. The thing for him is that it has NEVER worked since he bought it, and he doesn't have the time, money or patience to get it going and he'd rather be relieved of the burden, have some money (maybe to help get his Scully 280 1" 8-track going) and be able to move on knowing its gone to a good home. He's ready to tear it down and part it on eBay if I don't want it and I say that just to clarify where he is at emotionally-speaking in terms of committment to the machine.

The price of the the plastic vacuum impregnation on Matilda's flywheel (oh that sounded odd) is not the only cost you should think about for keeping Matilda around. She, (and all tape machines) is going to require major spare parts throughout her life to keep her going, and she will probably be unpredictable.

Oh yes, absolutely, though I have every reason to believe that once you get the bugs worked out of an MM-1000 it runs and runs and runs...George Schowerer and Skip Juried ran that AG-1000 at Mirasound night and day for three years without a hitch. But, yes, there are upkeep costs but I have every spare part imaginable here...literally...for the MM-1000. The vacuum sealing will likely cost me about $70.

You clearly have a deeply vested interest in this model of machine, too deep to cut and run now. I think that if the price is anywhere as "reasonable" as you claim, you should go for it, to have a nearly limitless spare part machine. (Or, make this your primary, and use Matilda for spares, whichever makes more sense.)

You are absolutely right...It wouldn't even be on the table for me if it wasn't an MM-1000. Part of why I like 'em so much is because they are so familiar...I mean, being able to step up to an MM-1000 that is alien to me and afer an hour have enough objective info to fill two pages and have made some repairs in the process...being able to hook test leads up to stuff without needing schematics...that has a lot of value to me. To be honest, chances are if I got this one it would be primary. I'll explain more below. Price? Dunno yet, but I think I may have spent more on 16-track harnessing and accessories earlier this year for Matilda than I would pay for the 16-track...

The mechanical quietness of this 16 track raises a concern for me.

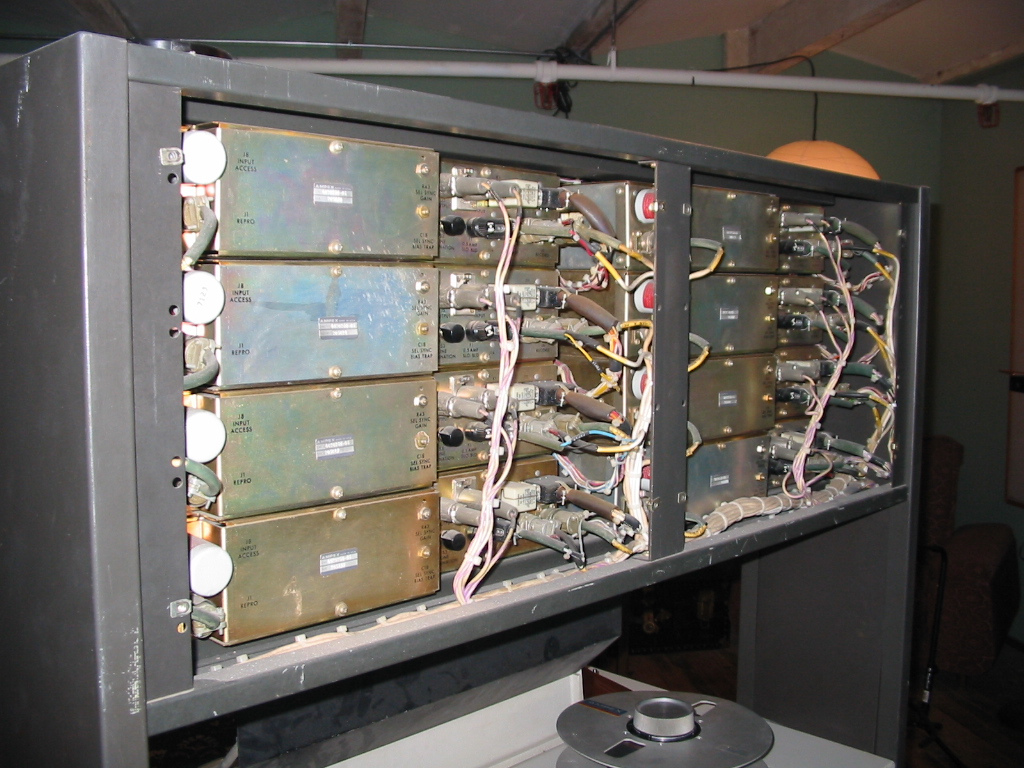

The picture shows this machine in the middle of an open room and the sides are removed from this deck. So, the noise levels may be misleading unless you have the machine closed up and in the same smaller environment, up against a wall, where Matilda resides.

Yeah, good points, Ghost, but I know these machines very well if I may be that bold. It wasn't a "hm...that seems like maybe its a little quieter..." it was a clear "WTH?! Why isn't MINE like that??" The room that the 16-track in is a good sized room but the ceiling is pretty low with deep exposed ceiling beams...its actually a pretty dead room, and keep in mind that the front of mine is open, and I often have it running with the side panels off. The 16-track sounded like a totally different machine. Not bad, just quieter in a sewing machine kind of way. I really do think my MM-1000 is pre-production. My capstan shaft is always on when the machine is on. I know of two machines other than mine now where the capstan shuts off when tape is unloaded and the wiring to accomplish this is clearly factory. I bet my capstan assembly has spent a lot of time idling. It was used for video sweetening at Universal Studios...likely spent days and days and days powered up just idling in between working. I am, without a doubt, convinced it is quieter. MUCH quieter.

Cory, I would be otherwise worried, for a gillion reasons like if you were talking a different machine altogether, back to square one sort of deal but ... but ... I think at this point, you're aware of all of this (plus much more) so anything reasonable to get the MM-1000 up and ready IS a good and reasonable idea.

Yeah...there'd be stuff I'd want to transplant, but I feel like my work on Matilda has been of great value for the education, and so many of the transport bits are easy to swap, the same-same components that have had the bearings refreshed and stuff...the electronics, once I get them their juice, are ready to go. It would take 10 minutes to swap the control relay box and 24V power supplies to have those refreshed assemblies on board. That control relay box is essential to trouble-free operation. There is still lots I want to do to Matilda and its all pretty much centered around 16-track conversion...I know me on this point...I won't rest until it is done, and it seems like a real blessing to have a chance to get a machine that needs a good dusting/wipe-down, some component swapping and some troubleshooting but then play-time. It would take weeks...MONTHS off of the Matilda docket...

Nothing wrong with having 2 same machines of this vintage, for spares etc...

Ultimately I'd want it down to one machine with a smart store of spares. Ideally one machine would be able to be built up as a good 8-track and sold as a running machine.

I honestly was a bit nervous with the impregnation solution.. Not that I know something you don't but I speculated the cost would be huge and who knows what other gremlins may creep up.

You should read some of the dialog about this over on the Ampex List. The collective knowledge and experience of so many of those folks is just really...something. One of the members has experience doing this sort of procedure specific to Dow Corning fluid issues so I'm not the least bit worried.

I'm pretty sure that the flywheel in the 16-track is low on fluid too. In fact, after getting some very useful/helpful info from Jay McKnight on the subject I am convinced that most of the viscous damped flywheels out there are low. This is based on the behavior of the assembly stated by others. What has been assumed as the normal characteristics of the assembly I believe to actually be signs of low fluid level.

if you get that second machine, I just ask that you be careful not to put unnecessary servicing into it. I always thought when a certain machine was built, those 40 years ago, that everything there, all components work as a unit and to upgrade/update, change this or that, may cause an unwanted domino effect. If something works well, whatever component, I'd just leave it alone and maybe do simple routine maintenance, no matter how hard would be to do otherwise.

Yeah, I hear you. A significant part of my maturation during these "Ampex years" is that I have become better at listening to others that are in the know when they say "don't mess with that." And I've become much more discerning about what is okay to leave alone. Turns out (surpise-surprise) that on a 40+ year old heavy production machine there is often much that needs attention, but that is one reason I like the 16-track...it is straight, Daniel. Now, Matilda has cleaned up nice, but as a supposed pre-production machine that has been converted and reconverted and seen a lot of use, there is funkiness. A significant amount of time has gone to tracing down problems that are related to non-production wiring and such...having a machine that hasn't been touched and messed with is so much easier you know?

If it's "cheap", like if he's practically giving it away, and you know you at least have good parts in there, then go for it. Cory, are you planning to replace what's needed on your current "restoration in progress" machine with the second machine's parts or do you plan to start from scratch on this "new" machine? It's just that you put so much time into the current one and starting from scratch, a new restoration, would worry me a bit .... but, to just replace faulty parts, sure, I see that easily...

Truly hard for me to say yet. I'm pretty sure I could sell the electronics modules I kept from the parted 440-8 which I intended for channels 9~16 and have my purchase money back. There are a number of things I could clean out...and then swap in the stuff I've rebuilt into the 16-track without too much trouble...I really am pretty quick getting stuff in and out of an MM-1000 by this point. Lots to ponder still, but it is worth pondering. The decision will be based on whether or not I can

realistically be ahead in time and money. I need more of both at the moment.