Yah.

More thoughts...

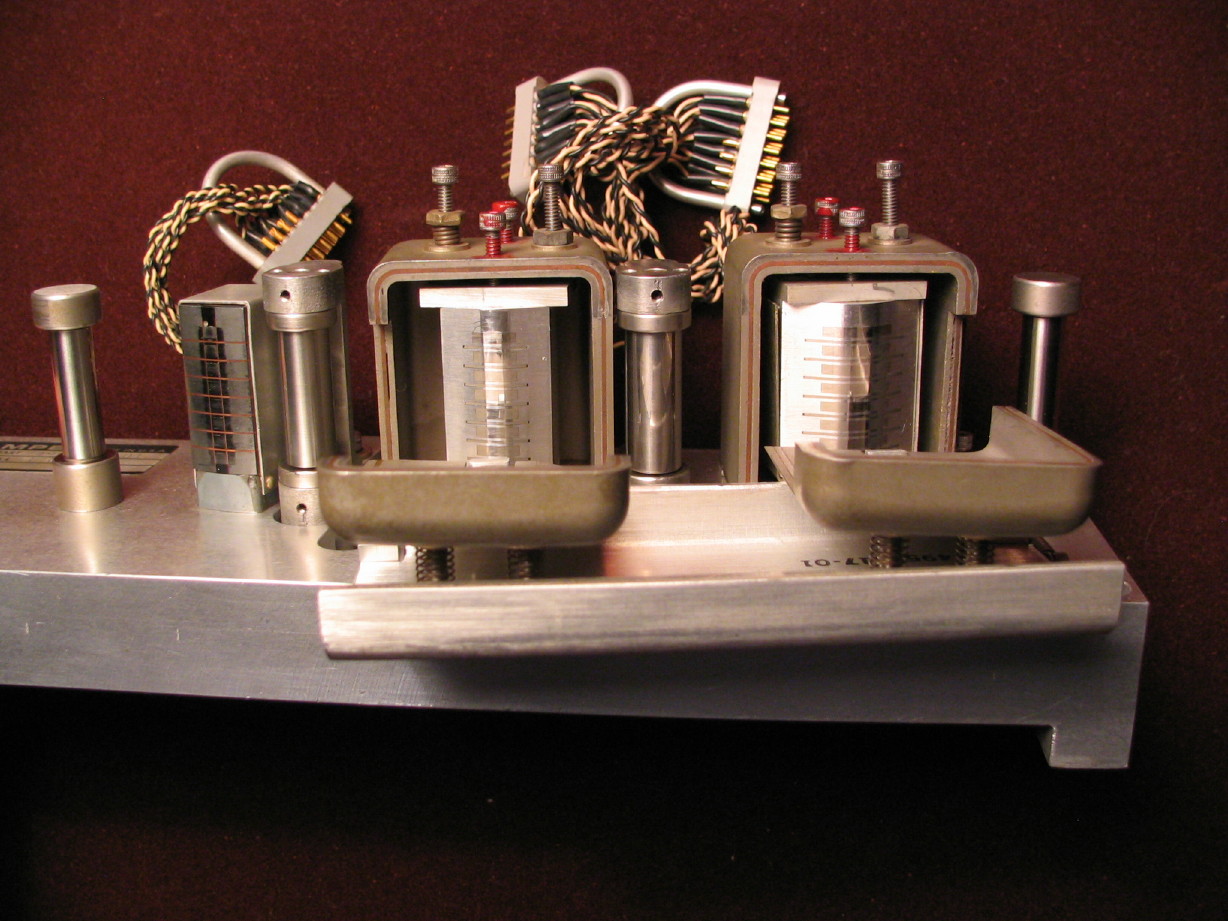

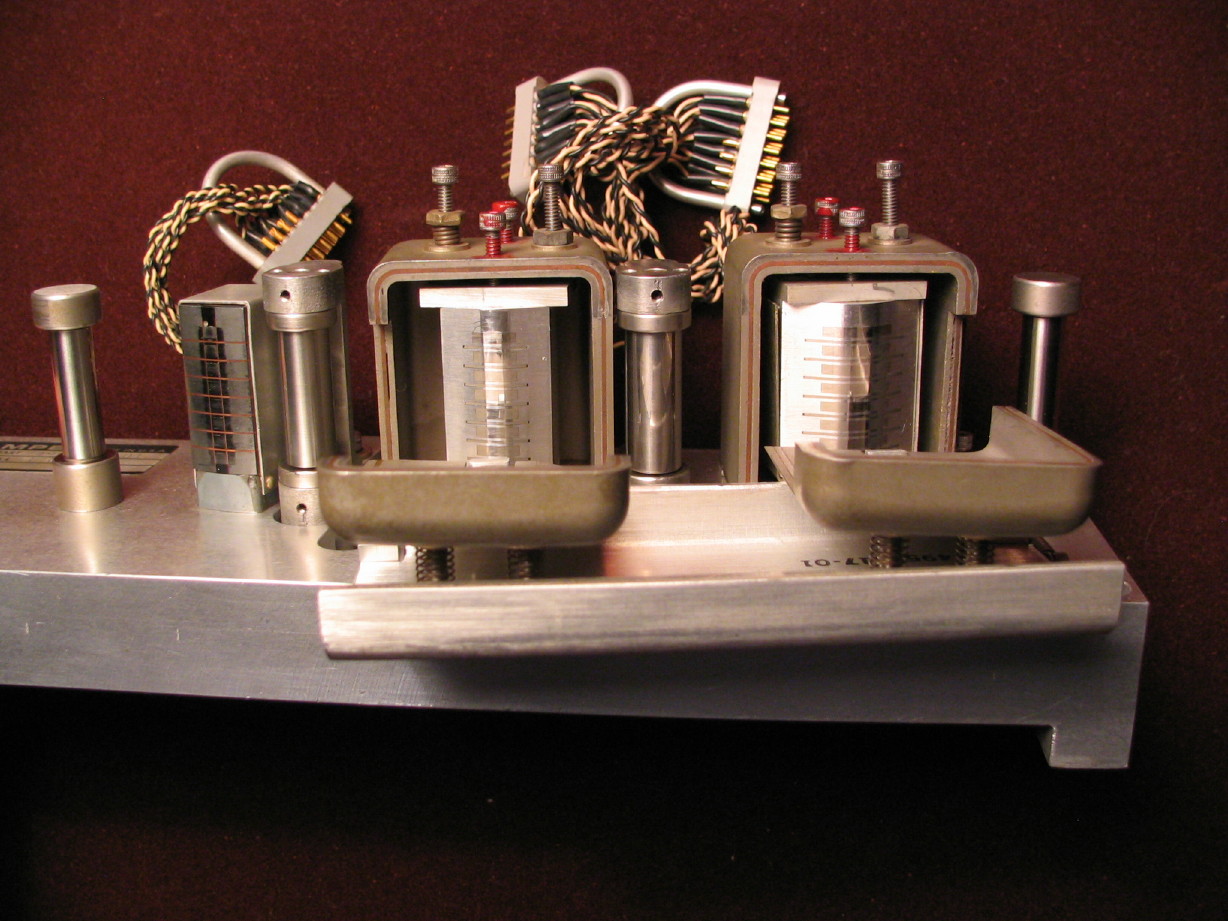

See, the rolling guide right before the erase heads helps to prevent scrape flutter being developed at that guide, AND the erase head, and then notice on the 2" blocks the next thing the tape sees after the erase head is the record head. So with the rolling guide the only thing to produce scrape flutter prior to the record head on the headblock is the erase head. No way around that. On the 1" MM-1000 there's that secondary scrape flutter idler in between the erase and record heads...see it?

So on the 1" MM-1000, you get some scrape flutter damping at the reel idler (the one with the viscous flywheel) which comes right before that incoming guide to the headblock (before the erase head), and then the scrape flutter that is developed at the erase head gets diminished by that first scrape flutter idler, and then the scrape flutter that is developed at the record head gets diminished by the next scrape flutter idler. So there are really 3 scrape flutter damping devices on the MM-1000, and with the static guide replaced with a rolling guide there before the erase head the ONLY thing that can cause scrape flutter is the supply side brake arm which has a static post, and fortunately the wrap angle is really small there and there is very little pressure on the tape from that thing.

NOW...is it necessary to have a tape path

filled with all sorts of rolling things? Well, not necessarily, and typically it is better to have less. Its not that simple. The more

things there are in the tape path there more opportunity for either scrape flutter or mechanical vibrations or "noise" becoming a component. Scrape flutter is defined by the total wrap angle of static components in the tape path (which primarily effects the amplitude of the scrape flutter)

prior to the capstan shaft, as well as the length of unsupported tape (which drives the frequency components of the scrape flutter...great length of unsupported tape means lower frequency components which means the scrape flutter may be more audible). My wrap angle sum is really low, the length of unsupported tape is relatively high. The bearings have to be good as does the surface of those rolling guides. All that stuff can put you back where you started if it is not right. And recall that Ampex went to the trouble of utilizing ruby bearings in their scrape flutter idlers...very very smooth with great wear characteristics. This is how Ampex addressed some of the compromises of adding all these rolling thingies to deal with the long tape path, which, again, is due to the fact that the MM-1000 is a converted quad VTR and the video heads are missing on the MM-1000, but the spaces are still there. Fun character. Now as you start looking at your own tape decks and analyzing "hey that's not a rolling thingy and the angle of that andandand..." just remember that I probably won't be able to hear the difference from installing that rolling guide there before the erase head. Why did I do it? Because...because I can, and it looks great, and it can't hurt, and I wanted to. Can't wait to see what the 440-8 rotary guide looks like out there before the head cover...have to find a 1/4"-28TPI x 1" flathead screw to mount it. Not easy. Probably have to get that up in Portland but I don't know when I can make it up there next.

By contrast here are a couple pictures below featuring (in order of appearance) the full MM-1000 tape path, the MM-1100 tape path (note that all three of those guides prior to the erase head can be rolling and one

was rolling in stock trim on the MM-1200...no viscous-damped reel idler on the MM-1100/1200 but there was a basic constant tension system so wow was improved), as well as the 3M M-79, which was preceded by the M-56 and the M-23...just notice the different ideas of the tape path, wrap angles, static and rolling components...more than one way to tackle it for sure. I believe the 3M decks feature the shortest amount of unsupported tape which puts the flutter frequency components out of the audio band...flutter amplitude is less of a concern then and therefore so is the wrap angle around those incoming and outgoing static guides. The MM-1100 was notorius when it was introduced for its flutter producing tape path...no scrape flutter idler on the original MM-1100's either...a relatively large degree of unsupported tape, lots of wrap angle and nothing to mitigate the scrape flutter.

Enjoy...