sweetbeats

Reel deep thoughts...

Now we're gettin' somewhere...

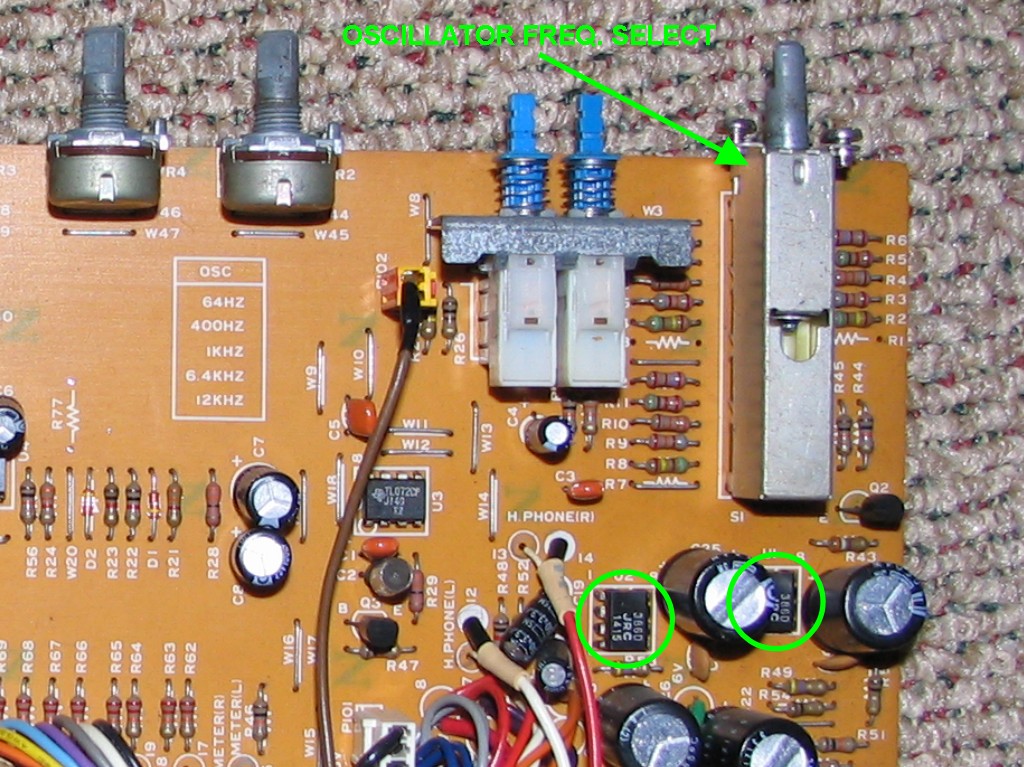

In the past week, here and there, I finished cleaning up the master fader, finished the recap job on the 4 Control Module main PCB's, and then last night stuffed and soldered in the new caps on both Balance Amp PCB's including some new resistors that had old bypass electrolytics on them...figured it'd be better just to pull the whole resistor/cap array and stuff with new rather than try to get the old cap off the resistor and clean up the resistor...was hoping I could fit both cap and resistor tails through the holes in the PCB, but they wouldn't fit and the pads are so small I figured it'd be better to piggy-back the caps on the resistor tails rather than drill out the holes...found a nice way to wrap the tails of the cap on the resistor so that there is a really nice weld between the two and the cap sits right on top of the resistor.

And the coup de gras to cap (sorry for the pun) off the evening was that I actually got the Control Module completely reassembled (except for the dress panel and knob and switch caps...leaving those off until after the smoke test).

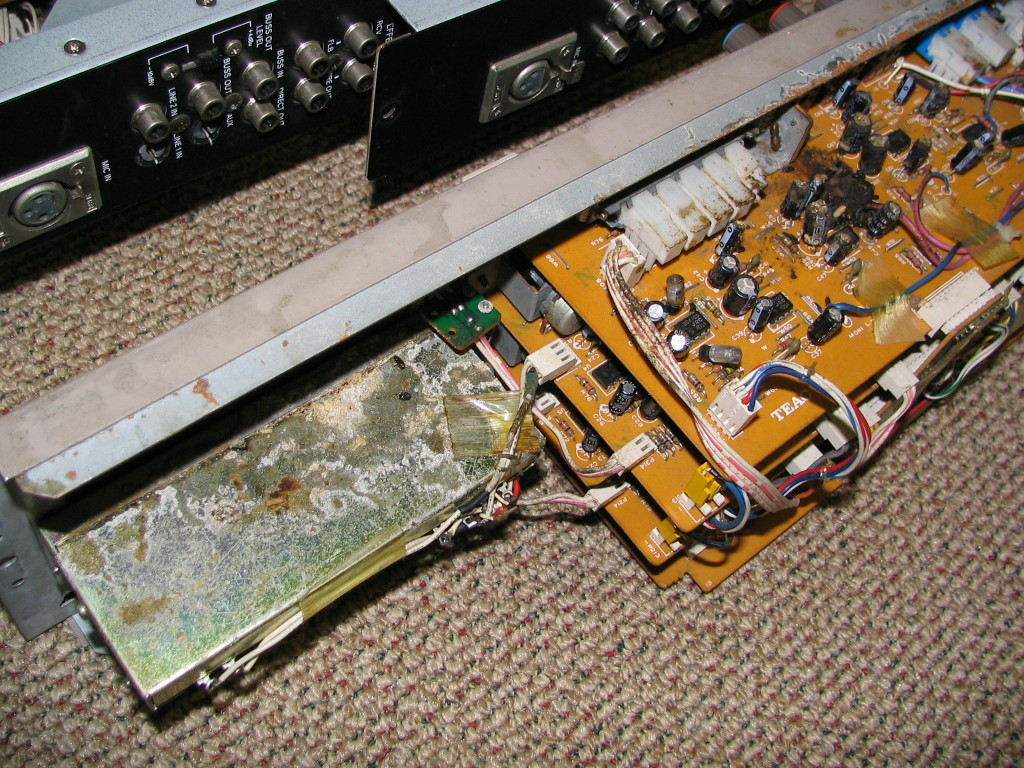

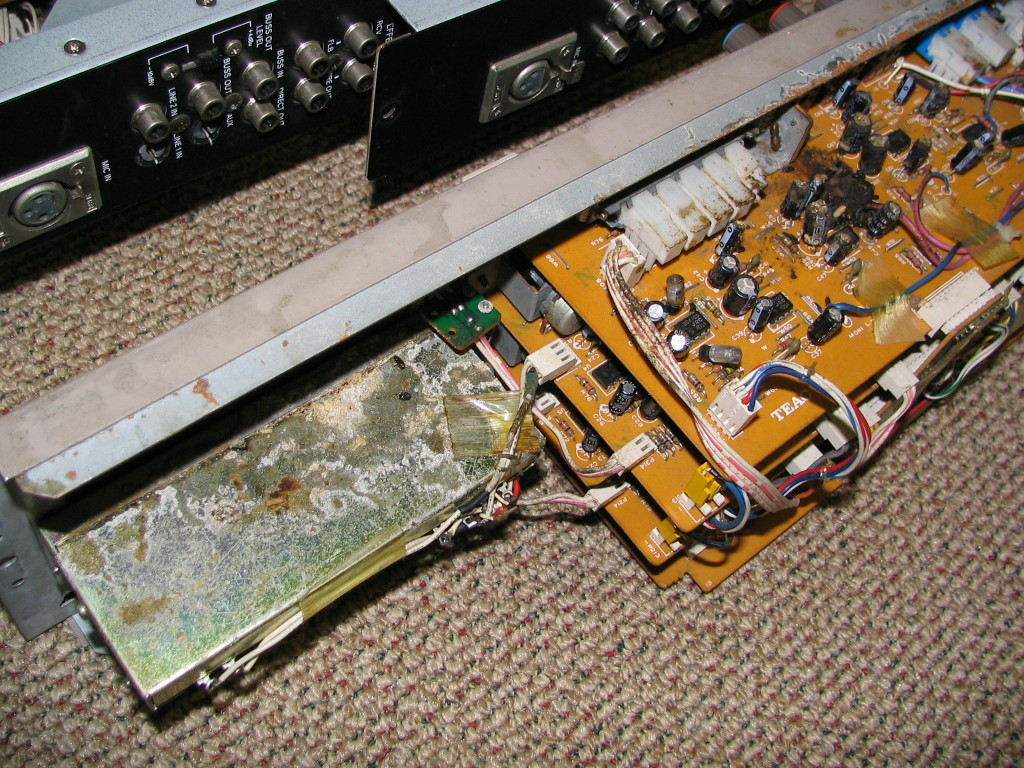

Remember this? This is a before of the master fader and the first PCB with the rodent excrement on it...the proverbial "before" picture:

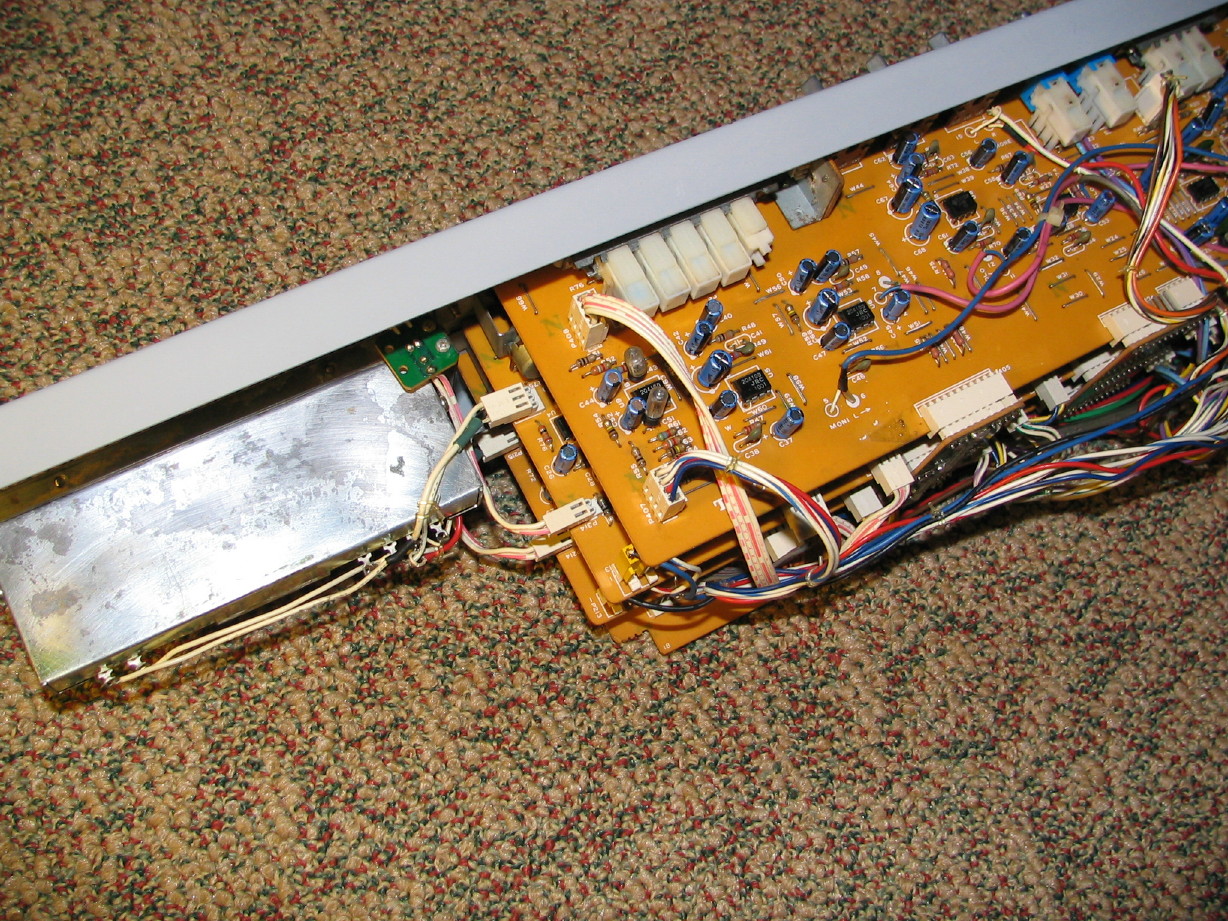

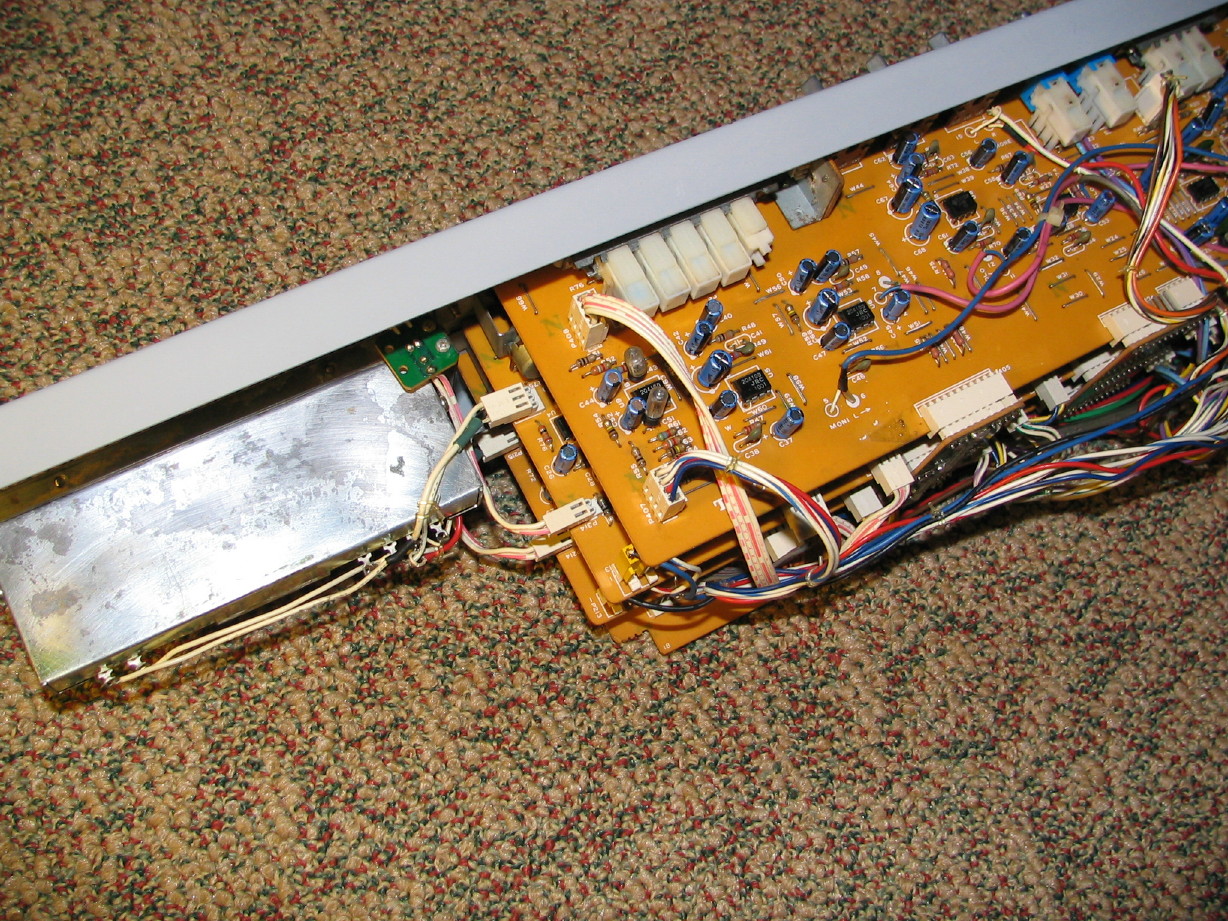

Here is the "after" pic:

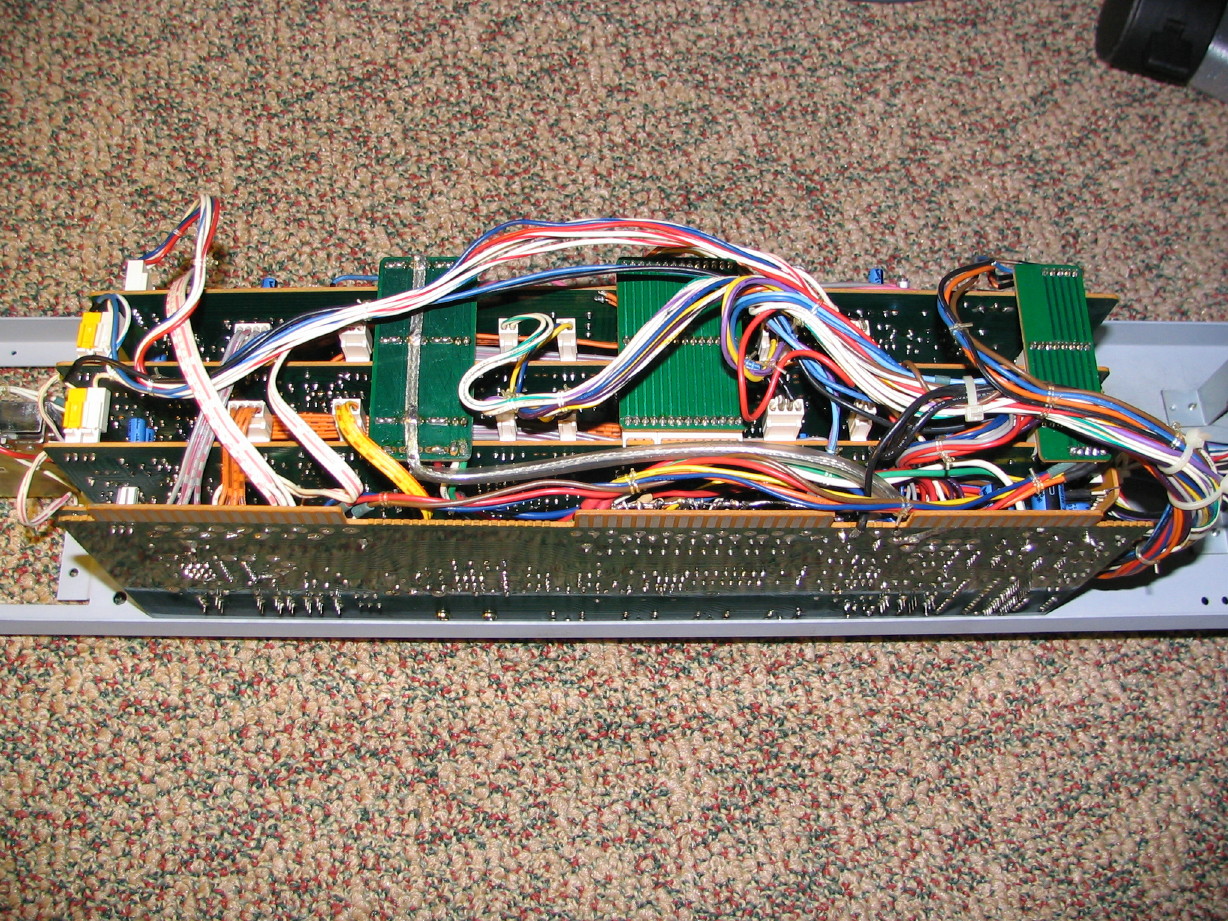

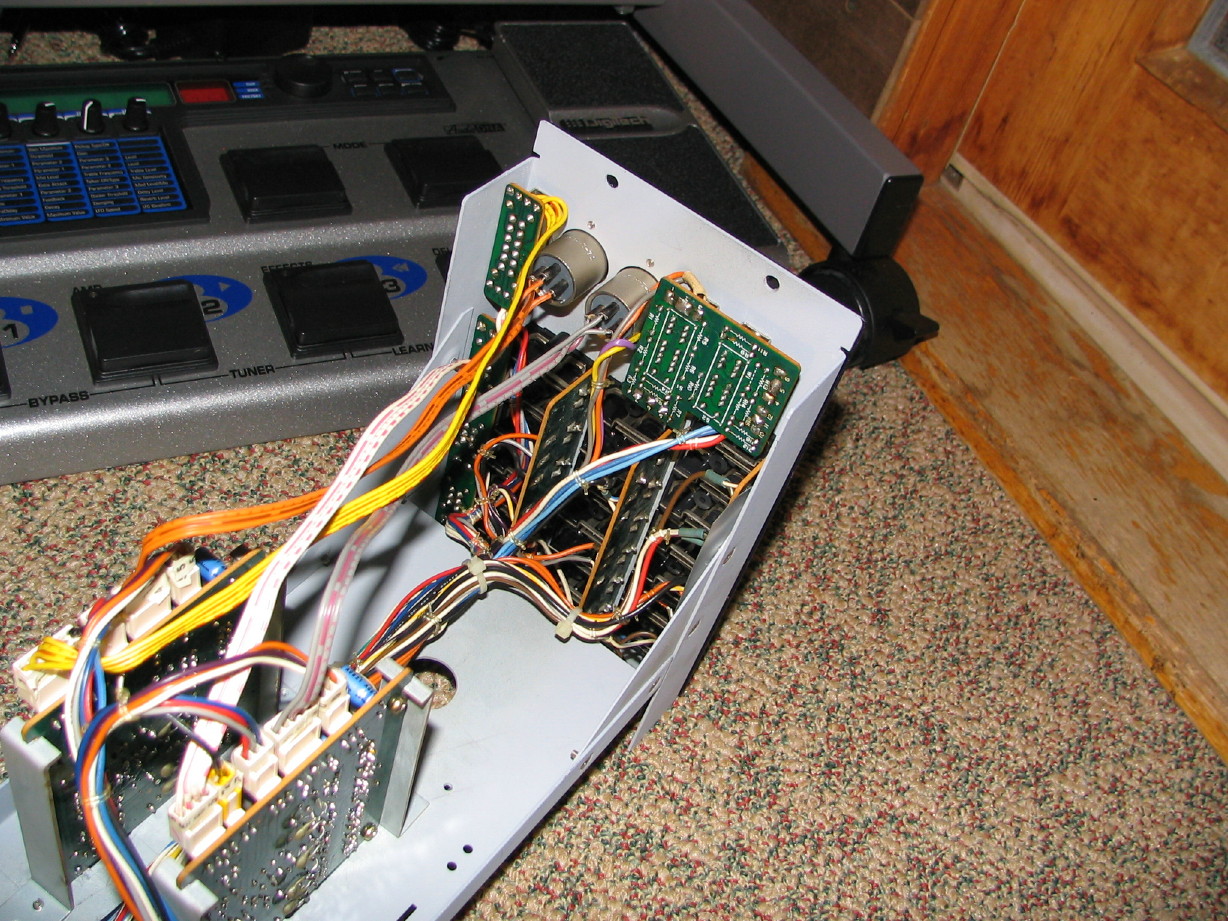

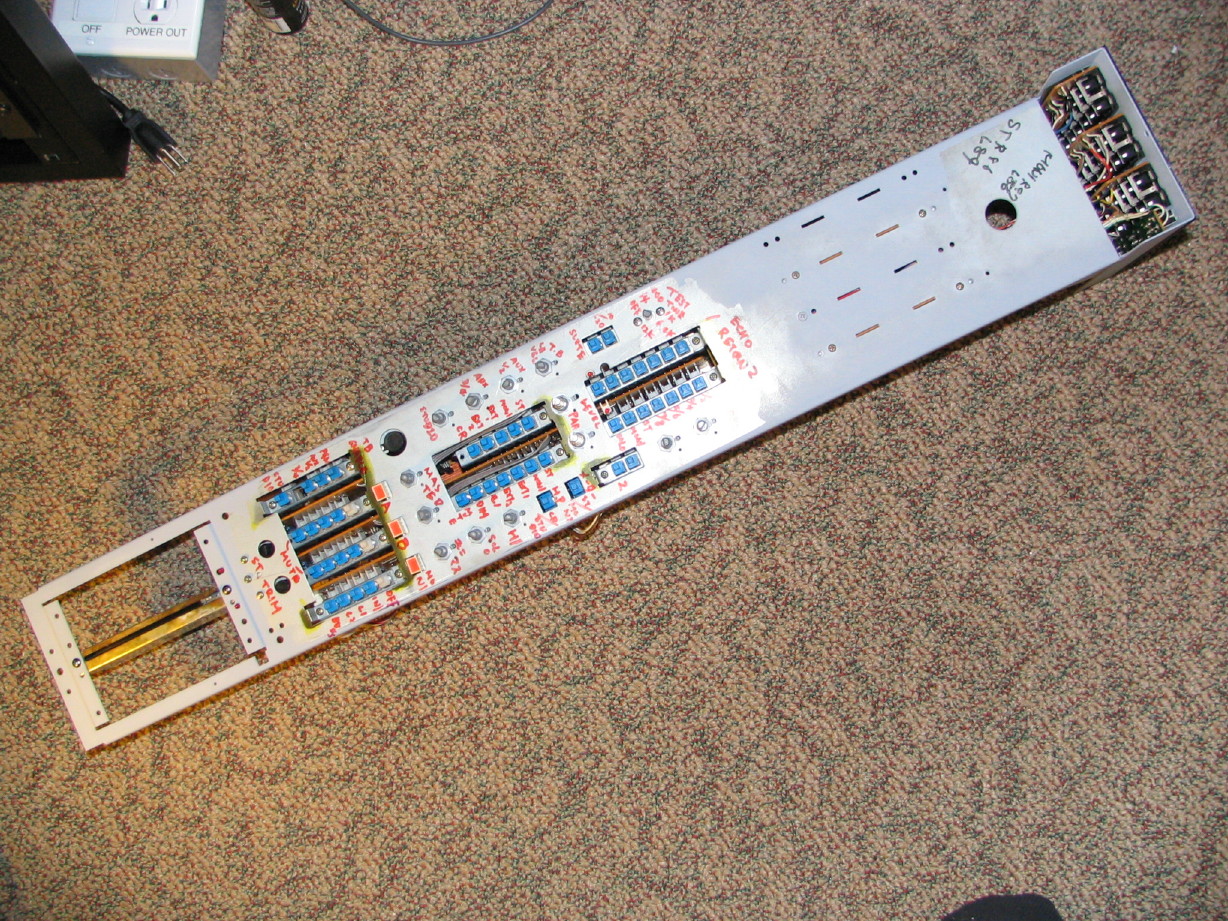

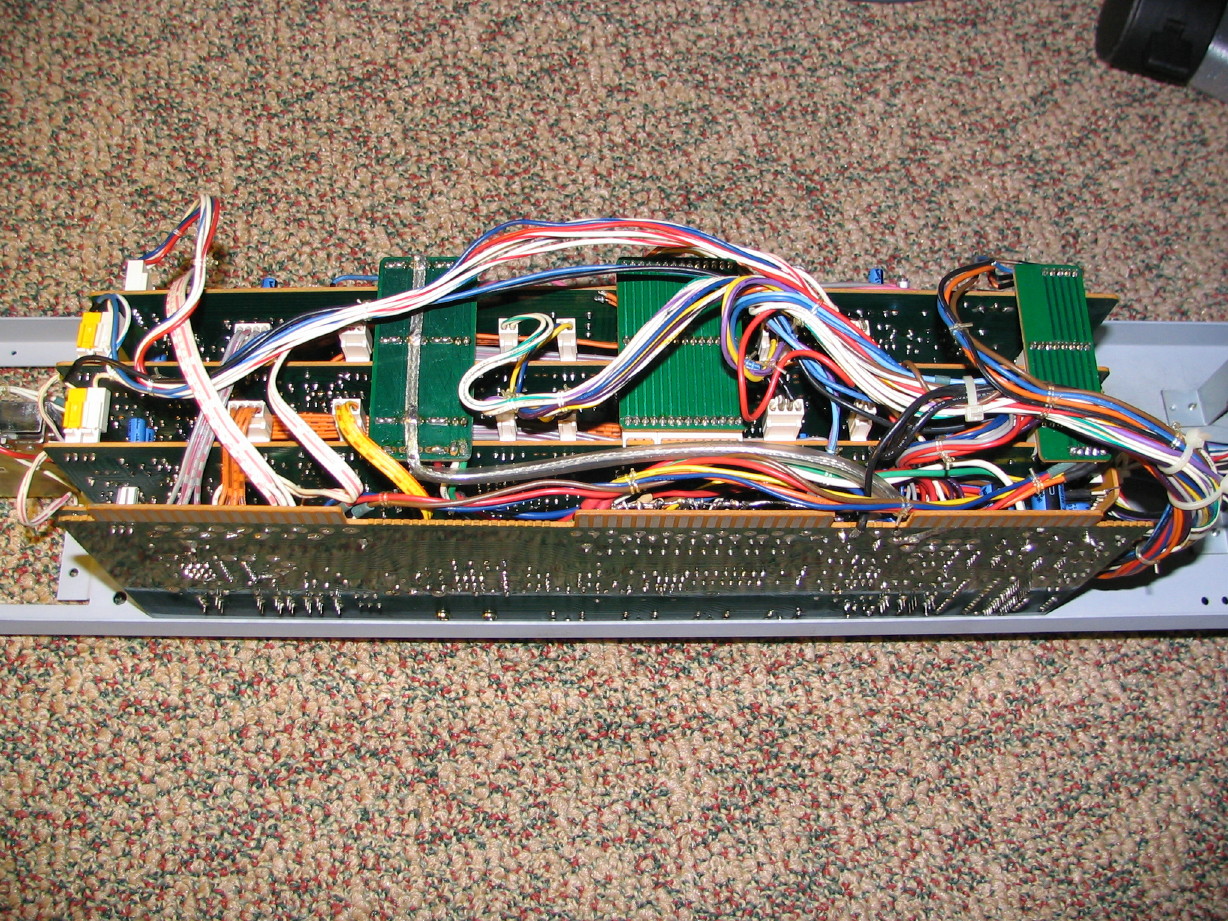

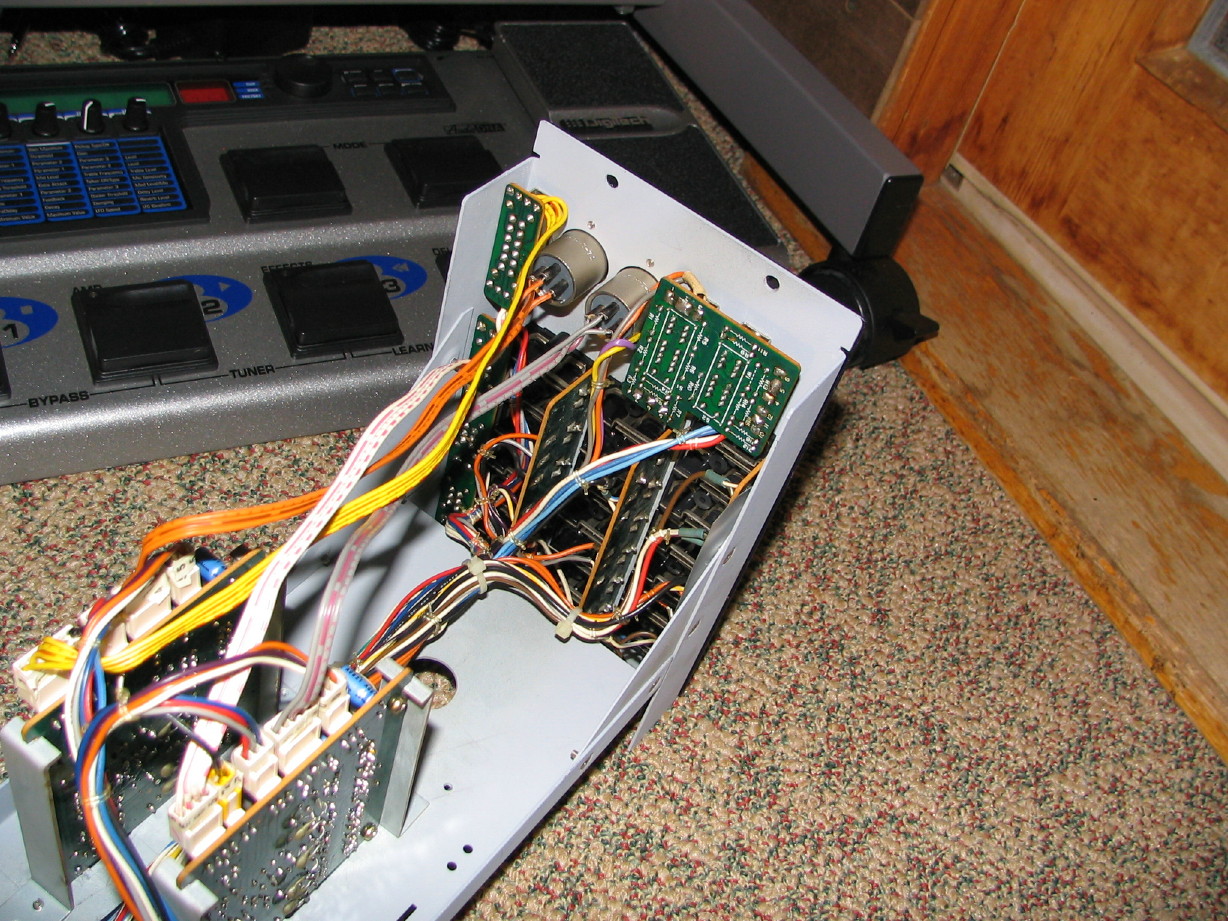

Here is a couple shots that cover the main PCB's and an internal shot of the jack panel:

Here is one of the top...doesn't look much different than before but it will once the dress panel and knob caps go on:

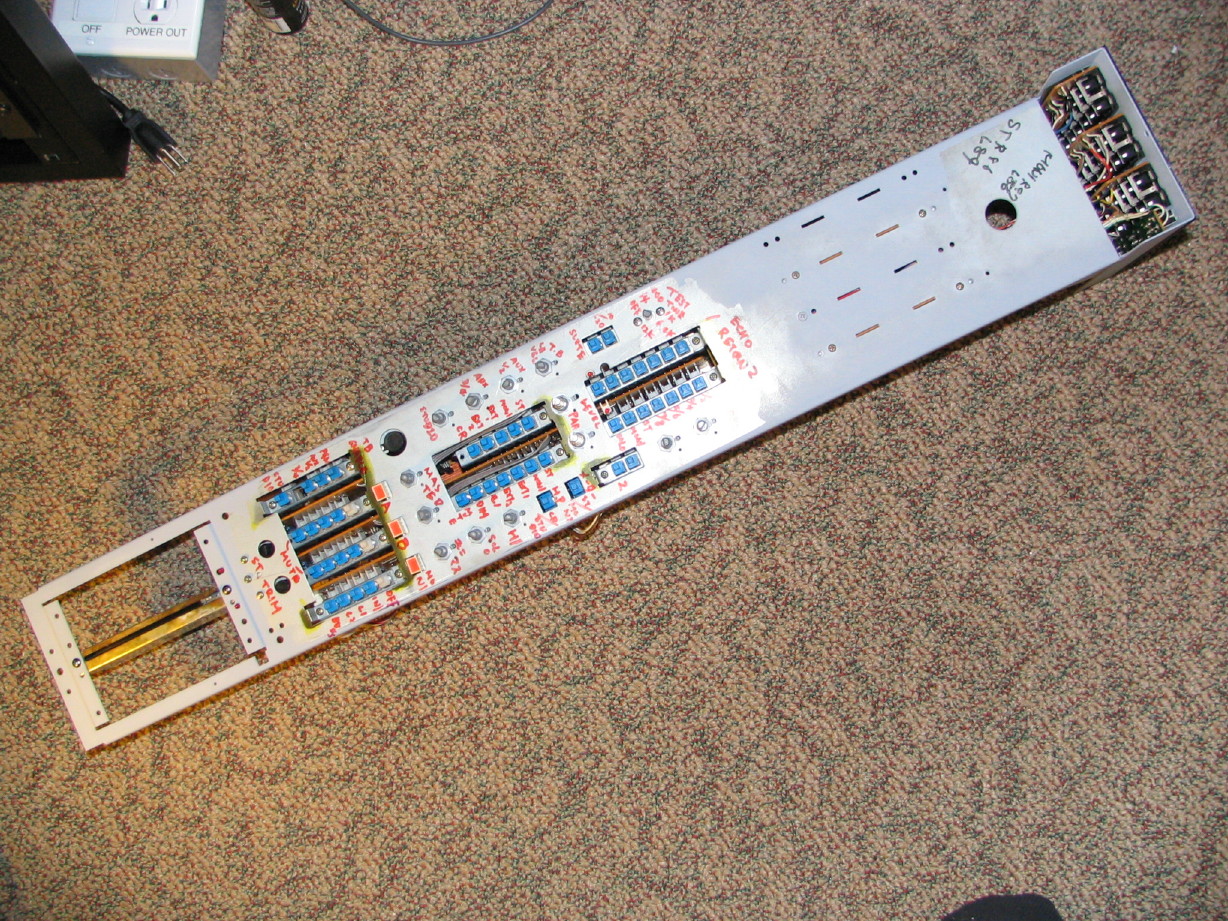

And finally here are a couple before shots of the jacks:

And here is the after:

Sometime in the next couple days I'll smoke test it, and if it passes that and some preliminary audio tests I'll put the dress panel and knob/switch caps back on.

and if it passes that and some preliminary audio tests I'll put the dress panel and knob/switch caps back on.

In the past week, here and there, I finished cleaning up the master fader, finished the recap job on the 4 Control Module main PCB's, and then last night stuffed and soldered in the new caps on both Balance Amp PCB's including some new resistors that had old bypass electrolytics on them...figured it'd be better just to pull the whole resistor/cap array and stuff with new rather than try to get the old cap off the resistor and clean up the resistor...was hoping I could fit both cap and resistor tails through the holes in the PCB, but they wouldn't fit and the pads are so small I figured it'd be better to piggy-back the caps on the resistor tails rather than drill out the holes...found a nice way to wrap the tails of the cap on the resistor so that there is a really nice weld between the two and the cap sits right on top of the resistor.

And the coup de gras to cap (sorry for the pun) off the evening was that I actually got the Control Module completely reassembled (except for the dress panel and knob and switch caps...leaving those off until after the smoke test).

Remember this? This is a before of the master fader and the first PCB with the rodent excrement on it...the proverbial "before" picture:

Here is the "after" pic:

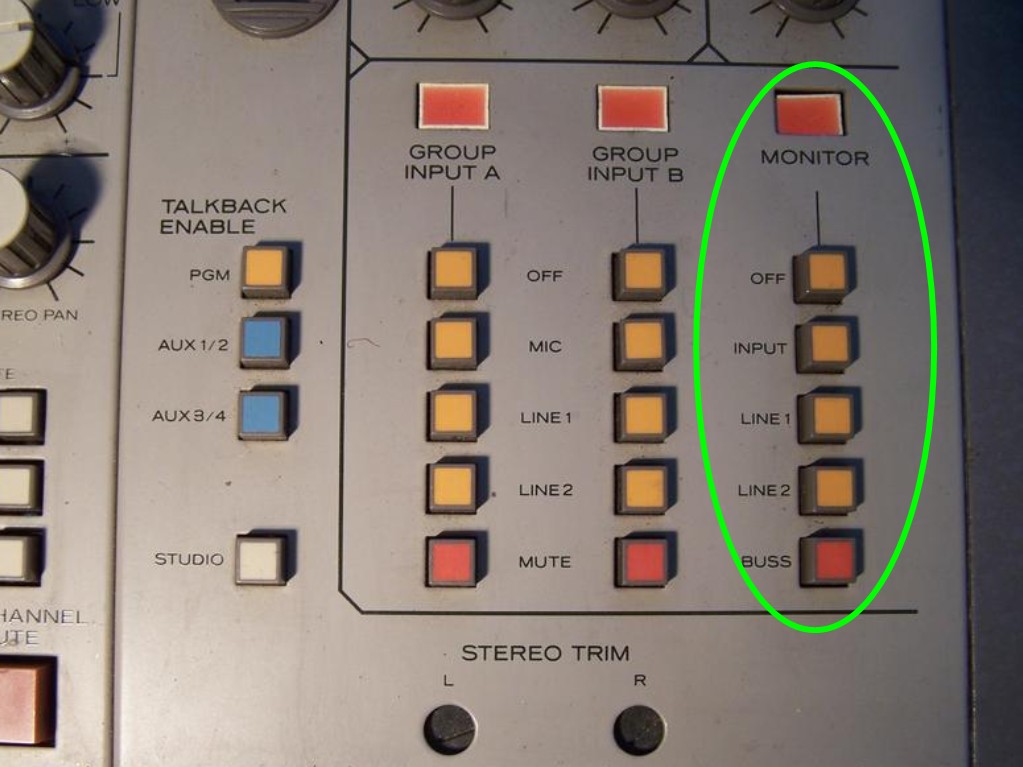

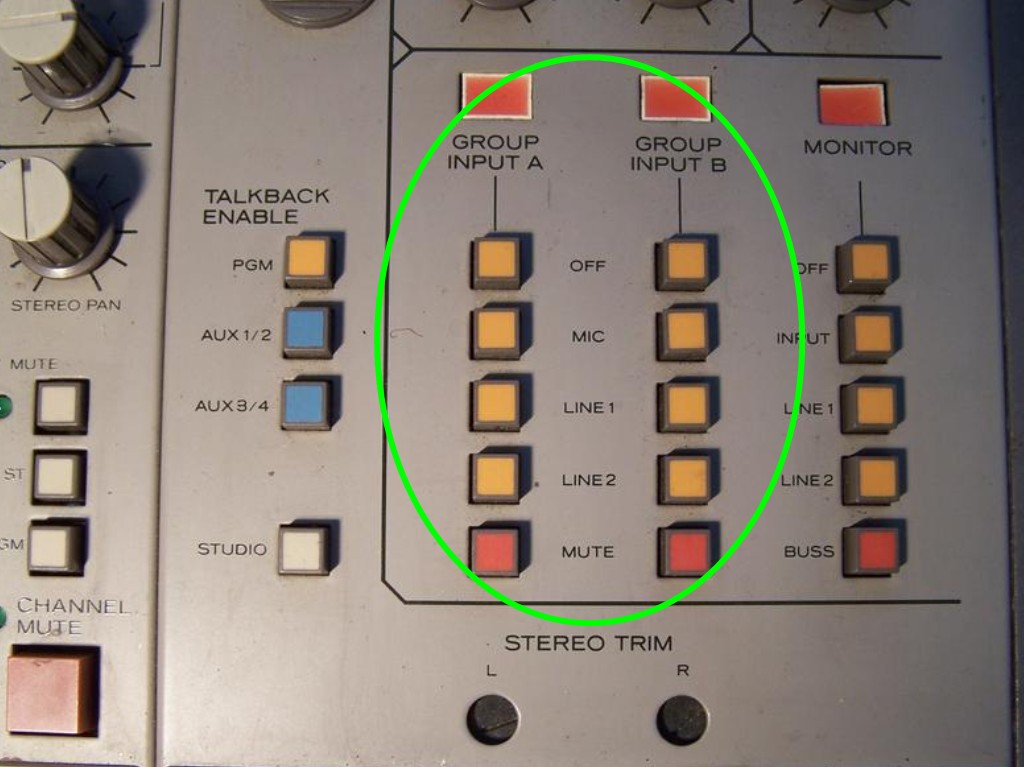

Here is a couple shots that cover the main PCB's and an internal shot of the jack panel:

Here is one of the top...doesn't look much different than before but it will once the dress panel and knob caps go on:

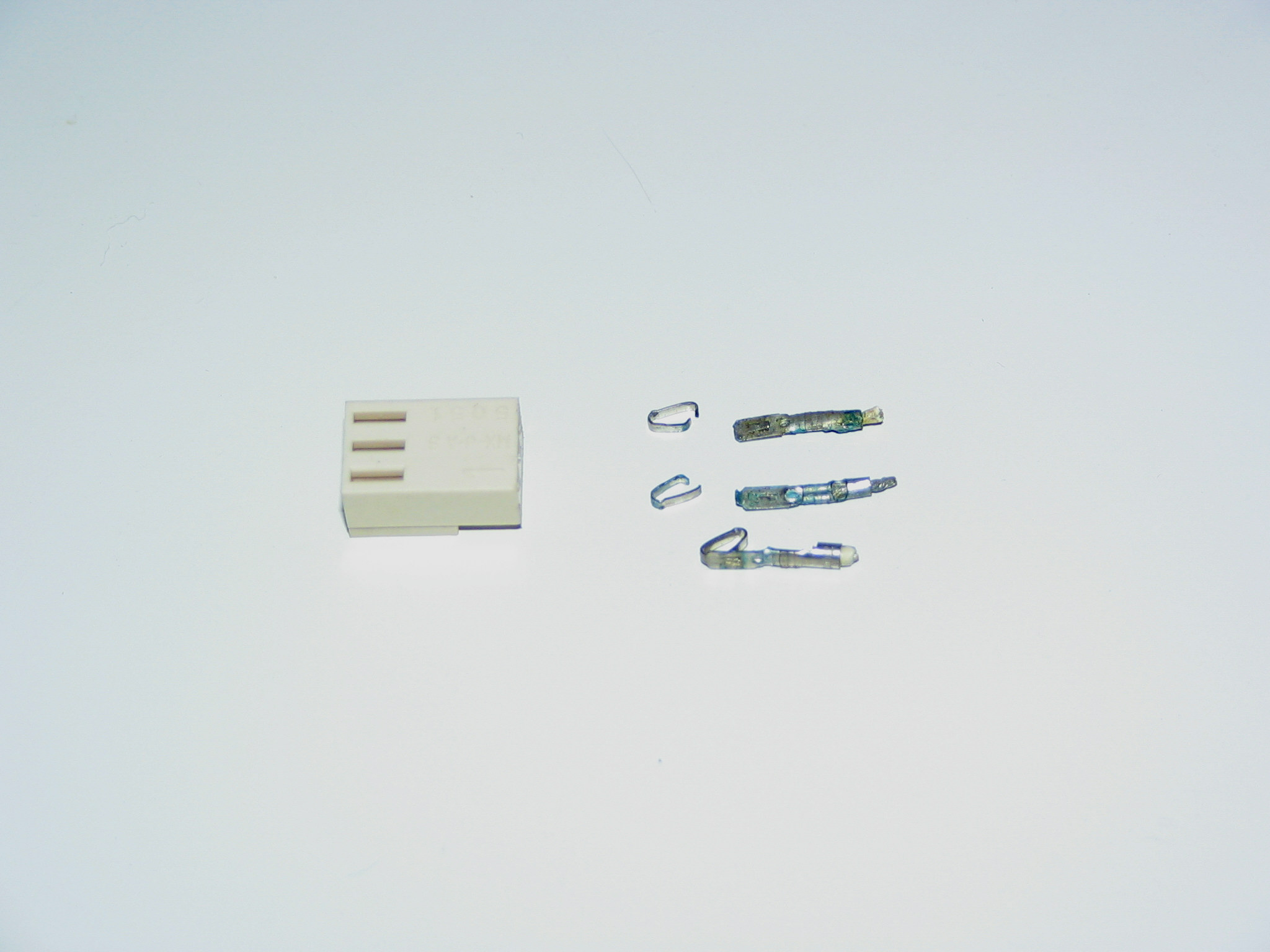

And finally here are a couple before shots of the jacks:

And here is the after:

Sometime in the next couple days I'll smoke test it,

and if it passes that and some preliminary audio tests I'll put the dress panel and knob/switch caps back on.

and if it passes that and some preliminary audio tests I'll put the dress panel and knob/switch caps back on.

Last edited:

It was the low band frequency sweep pot on the EQ board, and no I wasn't being obsessive. Didn't see it earlier but it had gotten bent so bad in the past that it wouldn't even turn. Now in my world that has to be fixed. Figured it wouldn't sustain straightening but I did my best. Secured the card to the channel frame via nutting some of the pots (of course including the bent one) and found a great wrench in the toolbox...just about fits over the pot shafts right. It is one I got to open/close the brake bleed valves on an Austin Mini I used to have. Anyway, snapped that sucker right away, but I happen to have a pot with the same body and shaft that was on a broken M-520 strip so I'll replace the shaft like I did on a couple others. This should be easier since it is not a stacked pot.

It was the low band frequency sweep pot on the EQ board, and no I wasn't being obsessive. Didn't see it earlier but it had gotten bent so bad in the past that it wouldn't even turn. Now in my world that has to be fixed. Figured it wouldn't sustain straightening but I did my best. Secured the card to the channel frame via nutting some of the pots (of course including the bent one) and found a great wrench in the toolbox...just about fits over the pot shafts right. It is one I got to open/close the brake bleed valves on an Austin Mini I used to have. Anyway, snapped that sucker right away, but I happen to have a pot with the same body and shaft that was on a broken M-520 strip so I'll replace the shaft like I did on a couple others. This should be easier since it is not a stacked pot.