sweetbeats

Reel deep thoughts...

Duh...

I figgered out the whole mic input pin assignment confusion...schemati 4-18 in the M-500 manual is a nice big wiring diagram that shows how all the guts interconnect...it includes the actual mic jack...the schemo for the channel card doesn't include the mic jack, just the connection from the input PCB (to which the mic jack connects). Why does this matter? Because XLR pin 1 goes to input PCB terminal 2, XLR pin 2 goes to PCB terminal 1, and then pin 3 to terminal 3. So what was confusing on schematic 4-15 is no confusion at all once you realize that what is shown as 'pin' 2 on the channel card PCB does not mean XLR pin 2...it is actually XLR pin 1, which makes sense.

Phew.

I figgered out the whole mic input pin assignment confusion...schemati 4-18 in the M-500 manual is a nice big wiring diagram that shows how all the guts interconnect...it includes the actual mic jack...the schemo for the channel card doesn't include the mic jack, just the connection from the input PCB (to which the mic jack connects). Why does this matter? Because XLR pin 1 goes to input PCB terminal 2, XLR pin 2 goes to PCB terminal 1, and then pin 3 to terminal 3. So what was confusing on schematic 4-15 is no confusion at all once you realize that what is shown as 'pin' 2 on the channel card PCB does not mean XLR pin 2...it is actually XLR pin 1, which makes sense.

Phew.

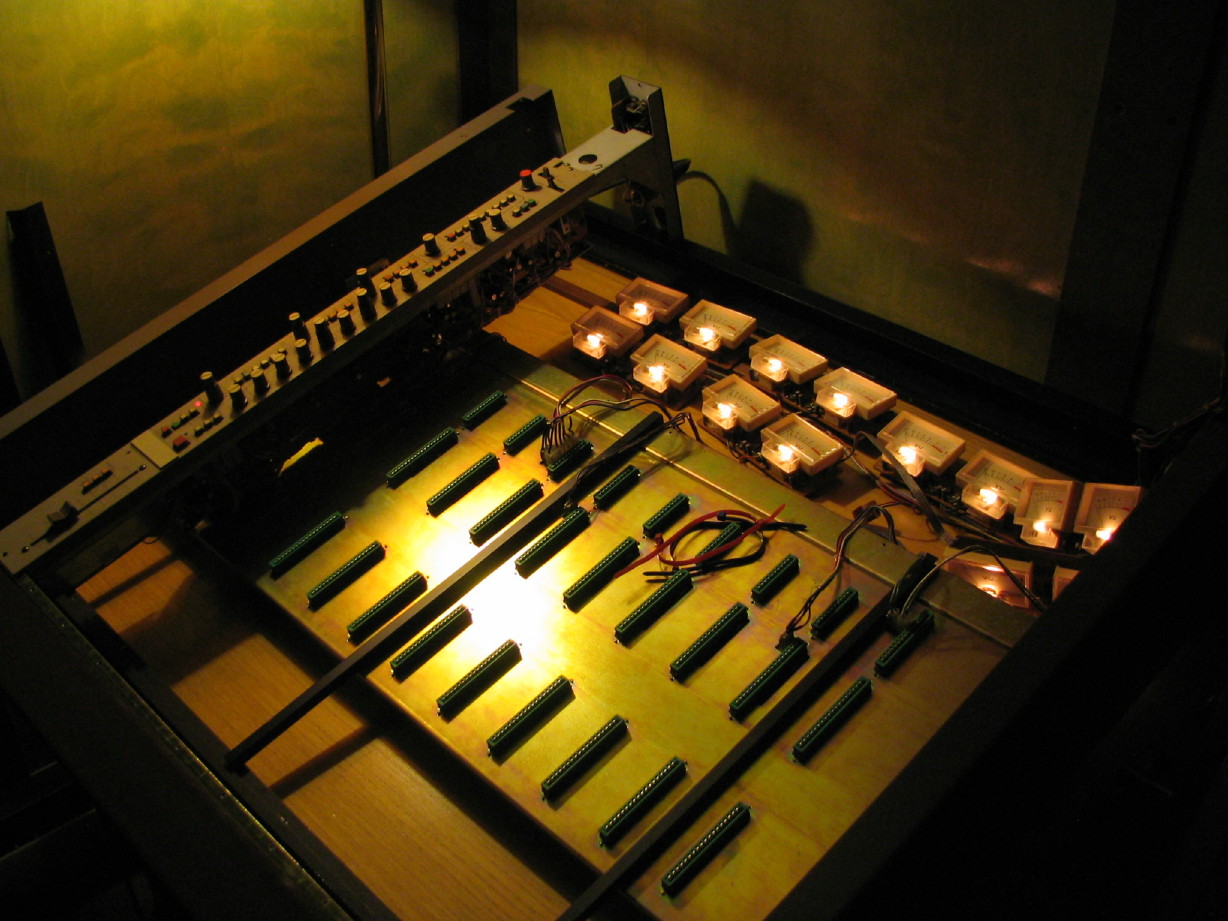

%20mod/0V(D)%20mod%20%231.JPG)

%20mod/0V(D)%20mod%20%232.JPG)

%20mod/0V(D)%20mod%20%233.JPG)

%20mod/0V(D)%20mod%20%234.JPG)

)

)

What a thread! That is just awsome SB! Looking forward for more!

What a thread! That is just awsome SB! Looking forward for more!