sweetbeats

Reel deep thoughts...

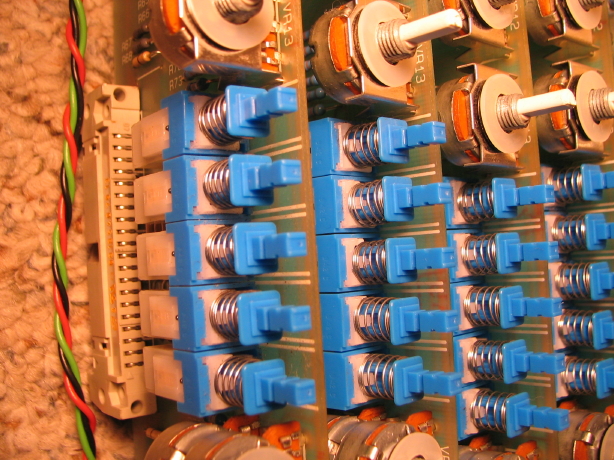

And then there were 16...

Last edited:

. If I don't see them by sometime later today I'll put 'em up.

. If I don't see them by sometime later today I'll put 'em up.

Looks AMAZING!!!

Nice work...both of you.

Well, first off, thanks for the kind words and glad you liked what I did with your shots.Yeah, kudos to Ghost...Jeff I still don't know how you crank those out so quick. The funny thing is, guys, I uploaded the D-SLR pics to the web server dayyyyys ago and just haven't had time to post the current status until early this morning, but Jeff started sending me renditions shortly after I uploaded the files several days ago! He was watching...annnnd waaaaiting....theyyyyyy're heeeeeeere!

It looks great Jeff...its not just the background but so much more and you do it so FAST! Its like a "Where's Waldo" to look for all the subtle touches...

We take Tascam manuals for granted...this manual is much more sparse and unrefined. It is a copy of the original manual. It covers the controls and all that and actually has a VERY good section on grounding, but there isn't really any application information.Doesn't the manual document any of that? Seems odd that such a task would be left to guessing, no?

Cheers!

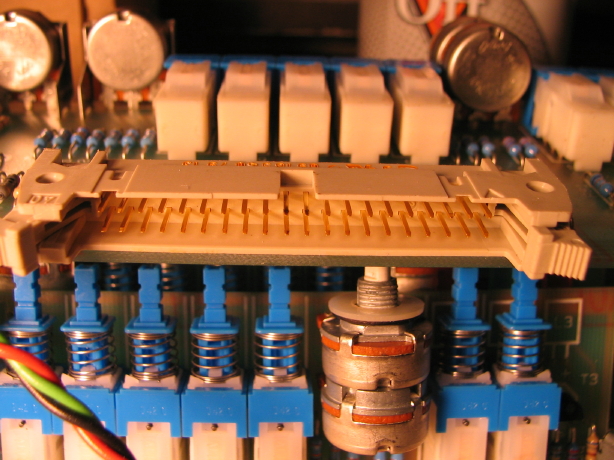

... Just wanted to say that this one's a keeper Cory (this and the MCI). I mean, what value can you put on such a detailed restoration job? I know it's probably never enough but still, most would never put in the time. So... my point is, there's more to this relationship that just routing signals or comparing a modern vs a more vintage or this and that..... but rather it is making music with a good friend that you got to know well inside and out..

... Just wanted to say that this one's a keeper Cory (this and the MCI). I mean, what value can you put on such a detailed restoration job? I know it's probably never enough but still, most would never put in the time. So... my point is, there's more to this relationship that just routing signals or comparing a modern vs a more vintage or this and that..... but rather it is making music with a good friend that you got to know well inside and out..  ...

...  .. and then, then.... you will have a more modern mixer but then there's also the MCI, which, I'm sure, will take its place right beside the Soundtracs. Keep 'em both, Cory, keep 'em both.... Wow, the sight will be something with Matilda in there as well! BTW, great photos Jeff.

.. and then, then.... you will have a more modern mixer but then there's also the MCI, which, I'm sure, will take its place right beside the Soundtracs. Keep 'em both, Cory, keep 'em both.... Wow, the sight will be something with Matilda in there as well! BTW, great photos Jeff.

Am I too late jumping in?... Just wanted to say that this one's a keeper Cory (this and the MCI). I mean, what value can you put on such a detailed restoration job? I know it's probably never enough but still, most would never put in the time. So... my point is, there's more to this relationship that just routing signals or comparing a modern vs a more vintage or this and that..... but rather it is making music with a good friend that you got to know well inside and out..

...

.. and then, then.... you will have a more modern mixer but then there's also the MCI, which, I'm sure, will take its place right beside the Soundtracs. Keep 'em both, Cory, keep 'em both.... Wow, the sight will be something with Matilda in there as well! BTW, great photos Jeff.