Okay...THAT didn't work...

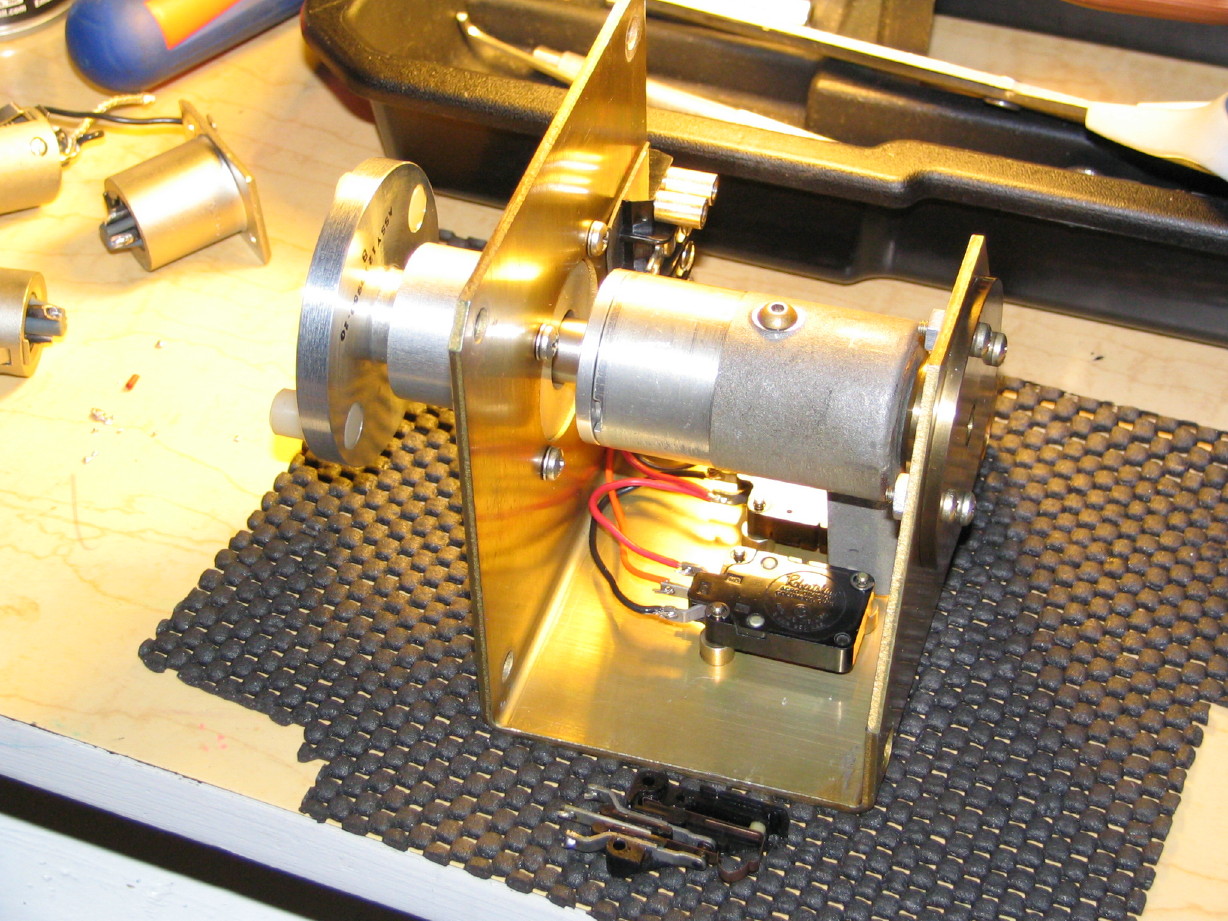

Well, I bolted up the motion sensor and it STILL doesn't actuate like it should in PLAY. Hm. There's just not enough drag to get that little paddle to close the new switch.

It turns out the assembly involves yet

another viscous coupling: the shaft from the disk that mates with the reel motor goes down inside the housing with the paddle that engages one switch or the other, okay? Well I thought it was just a friction fit between two surfaces but here is a fluid in there. Good news is that should last forever and be consistent in terms of avoiding wear on the shaft and housing surfaces...it makes sense to do it this way because the frictional coefficient needs to be consistent over time in order to maintain consistent performance, and this would not be the case between two hard surfaces as they wear.

ANYway...

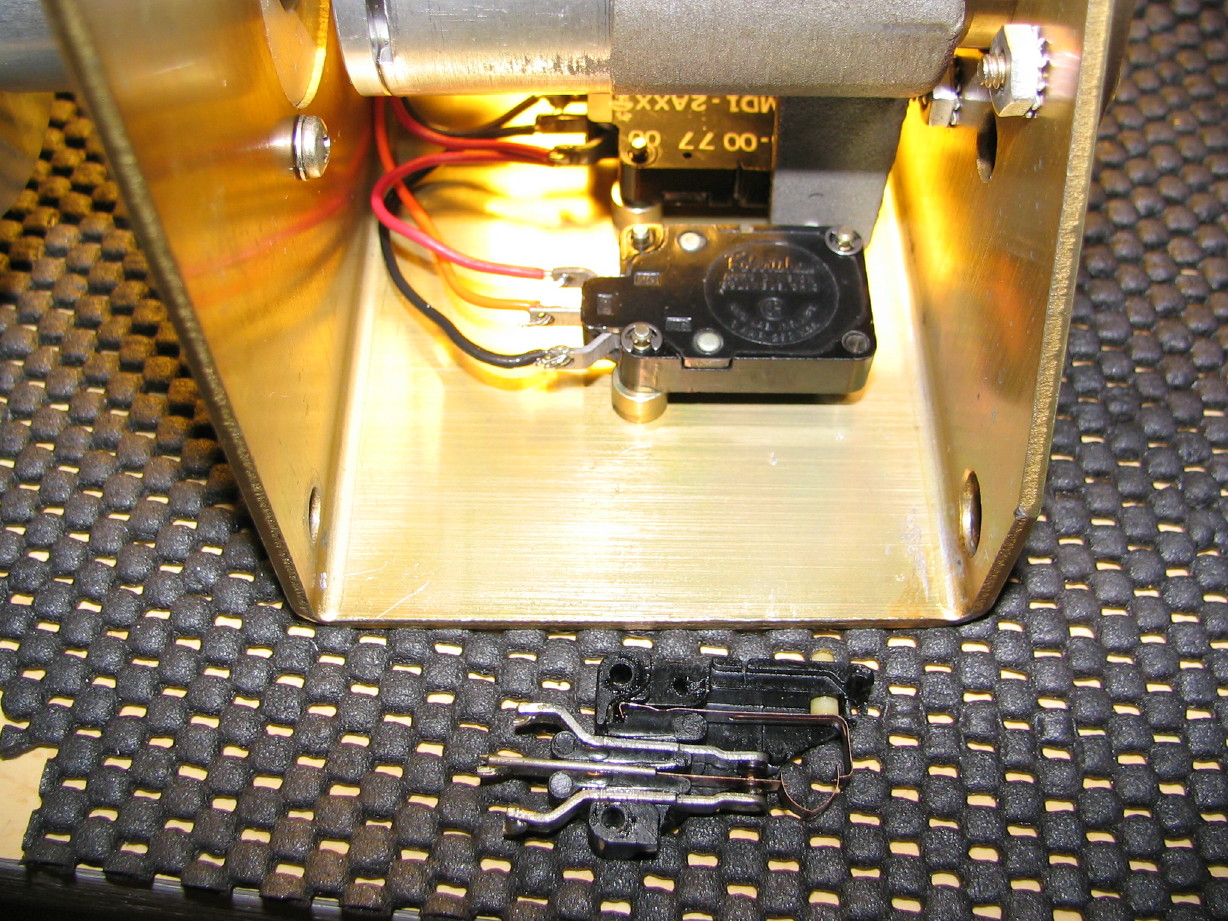

I figured "hey, maybe its low and I'll just add some more thick oil." Wrong. I used the closest thing I had to what is in the reel idler flywheel because I

assumed it was the same type of close-tolerance arrangement. Nope. I used my turbine oil. Figured I couldn't go wrong because its pretty heavy and very refined. It took it from not working right to not working at all. Slippery. I figured "Hey! I'll just pour everything out and put some HEAVIER oil in there. When I poured it out the turbine oil was mixed with a semi-gelatinous milky fluid. Dang. They had to put something WIERD in there. So I put some 80/90 gear oil in there...heavy oil. Nope. Still didn't work. I filled it up all the way thinking THAT would do the trick. Nope. But it did leak out the top as I as filling and make a mess. ARG!

So I took it all apart again to clean it all up, and it is devoid of any oil mess so that's good...got it on its side and I'm gonna leave it that way for a couple days maybe to drain as much as possible, but in the

meantime I've gotta try and figure out what was in there...it was, like, the consistency of freezer jam before you freeze it...when its still runny (sans berry chunks okay?)...thick and just a little jelly-like...man I'm up a creek if I can't figure this out...

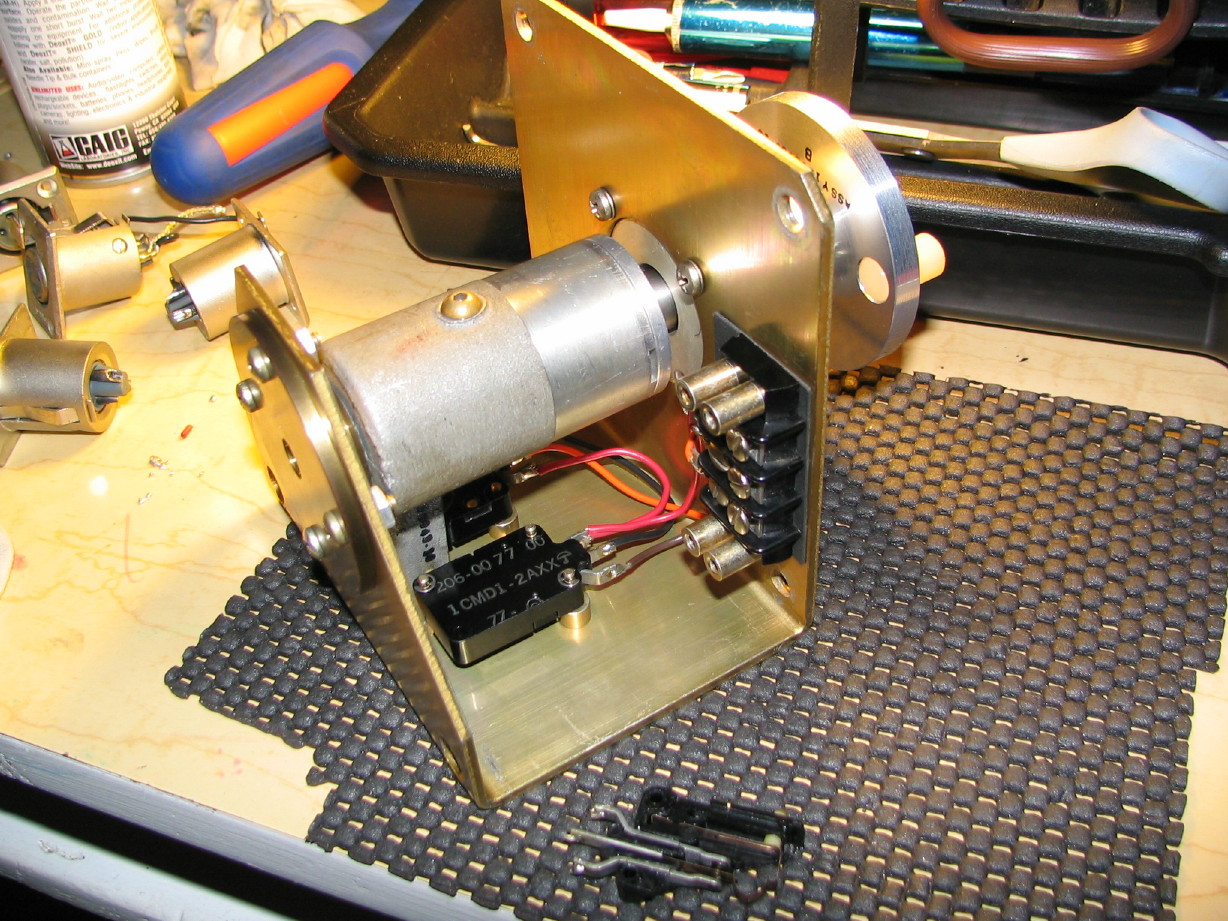

Oh and to add insult to injury its STILL doing that thing where it won't go into PLAY sometimes, even with the new switch installed on the motion sensor. I'm just going to go ahead and recap the Control Relay Box...there are only 5 caps in there and three of them have to do with time delay and holding voltage, and those three caps happen to be "Beaver" branded paper casing lytics which are NOTORIUS for going bad...I've already got some nice Vishay replacements so I'll put those in and see where we're at. Even if that doesn't fix it I know it needs to be done anyway so there you have it.

I believe it is my dodgey-busted-onitslastlegs switch that is the cause of my transport's intermittent willingness to enter PLAY mode. Its any easy swap so I'll know soon.

I believe it is my dodgey-busted-onitslastlegs switch that is the cause of my transport's intermittent willingness to enter PLAY mode. Its any easy swap so I'll know soon.

So I took it all apart again to clean it all up, and it is devoid of any oil mess so that's good...got it on its side and I'm gonna leave it that way for a couple days maybe to drain as much as possible, but in the meantime I've gotta try and figure out what was in there...it was, like, the consistency of freezer jam before you freeze it...when its still runny (sans berry chunks okay?)...thick and just a little jelly-like...man I'm up a creek if I can't figure this out...

So I took it all apart again to clean it all up, and it is devoid of any oil mess so that's good...got it on its side and I'm gonna leave it that way for a couple days maybe to drain as much as possible, but in the meantime I've gotta try and figure out what was in there...it was, like, the consistency of freezer jam before you freeze it...when its still runny (sans berry chunks okay?)...thick and just a little jelly-like...man I'm up a creek if I can't figure this out...

).

).