Heads relapped

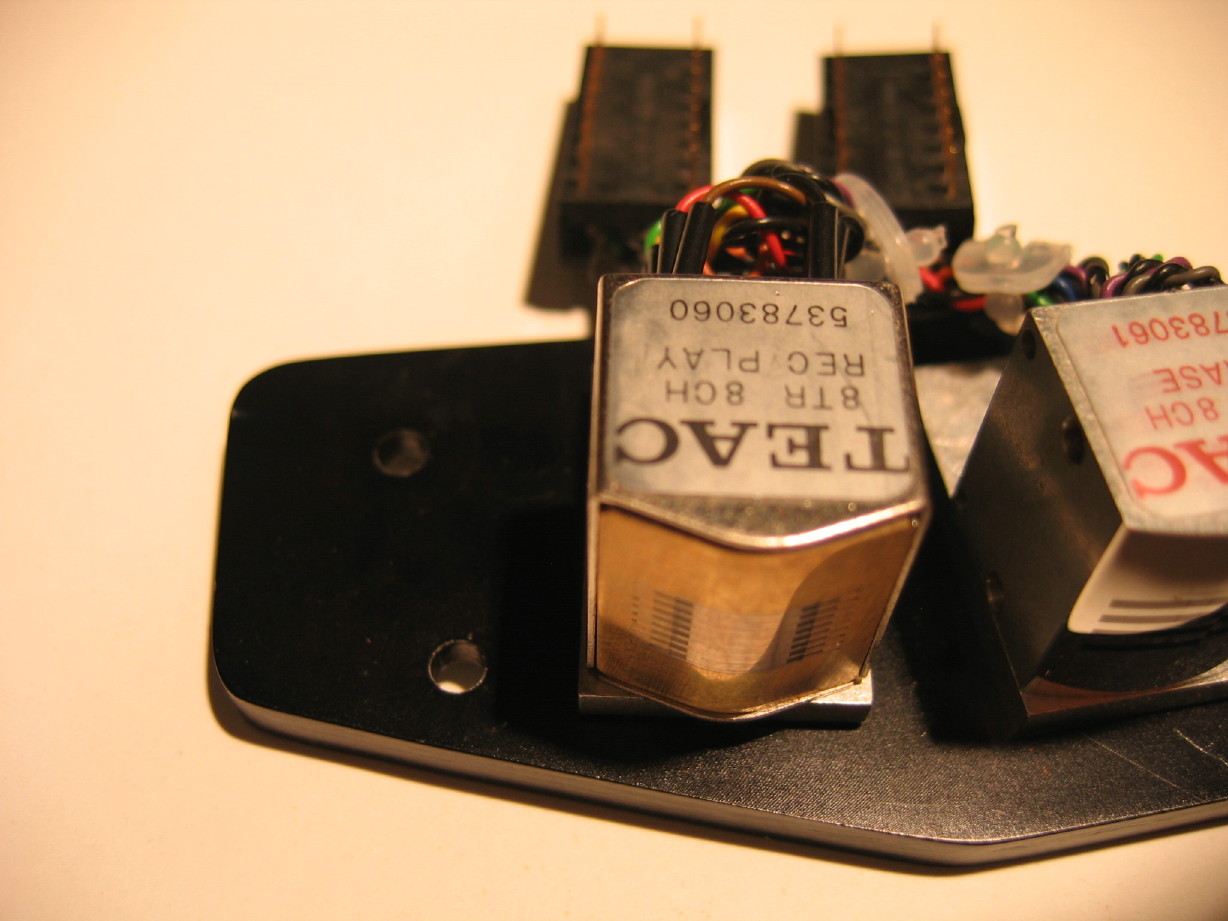

I recently enlisted help from evm1024 to relap the record/reproduce heads from the block that came with my 388 as well as the block that came with my parts 388. He did a fantastic job. Hopefully we're both happy with the transaction but I can't help feeling like I came out with the better end of the deal considering I now have two relapped record/reproduce heads which is just fantastic.

Ethan left the erase heads alone as the heads themselves are ferrite which, as I now know, is brittle and can micro fracture during the lapping and leave behind a surface that can damage the tape. Not a concern to leave it alone on my heads here as both erase heads have some wear in the aluminum, but the ferrite head surfaces are great. Erase heads typically have a much larger bearing surface and therefore aren't as great a concern when it comes to wear.

The reason I needed at least one of these record/reproduce heads relapped was, as I have mentioned in the past, because the wear groove was (I believe) from 457 which was slit slightly more narrow than the tape I'm using (and want to use) which is LPR35. So because the groove was more narrow than the LPR35 the tape would ride up slightly on track...1? Or track 8...I'll have to look back, but the point is it would deflect away from the head and the effected track would have a lower output by 3~6dB's, as well as a lower record level.

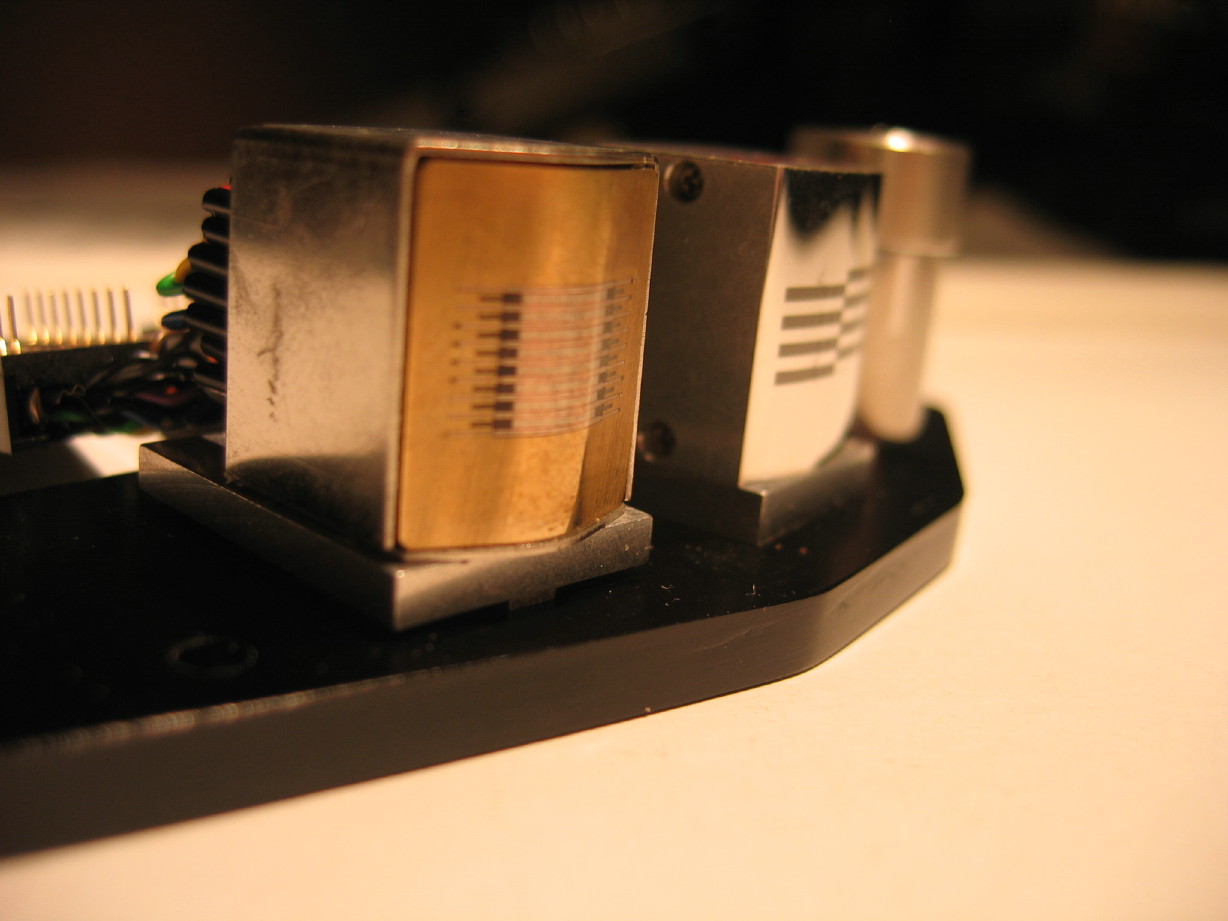

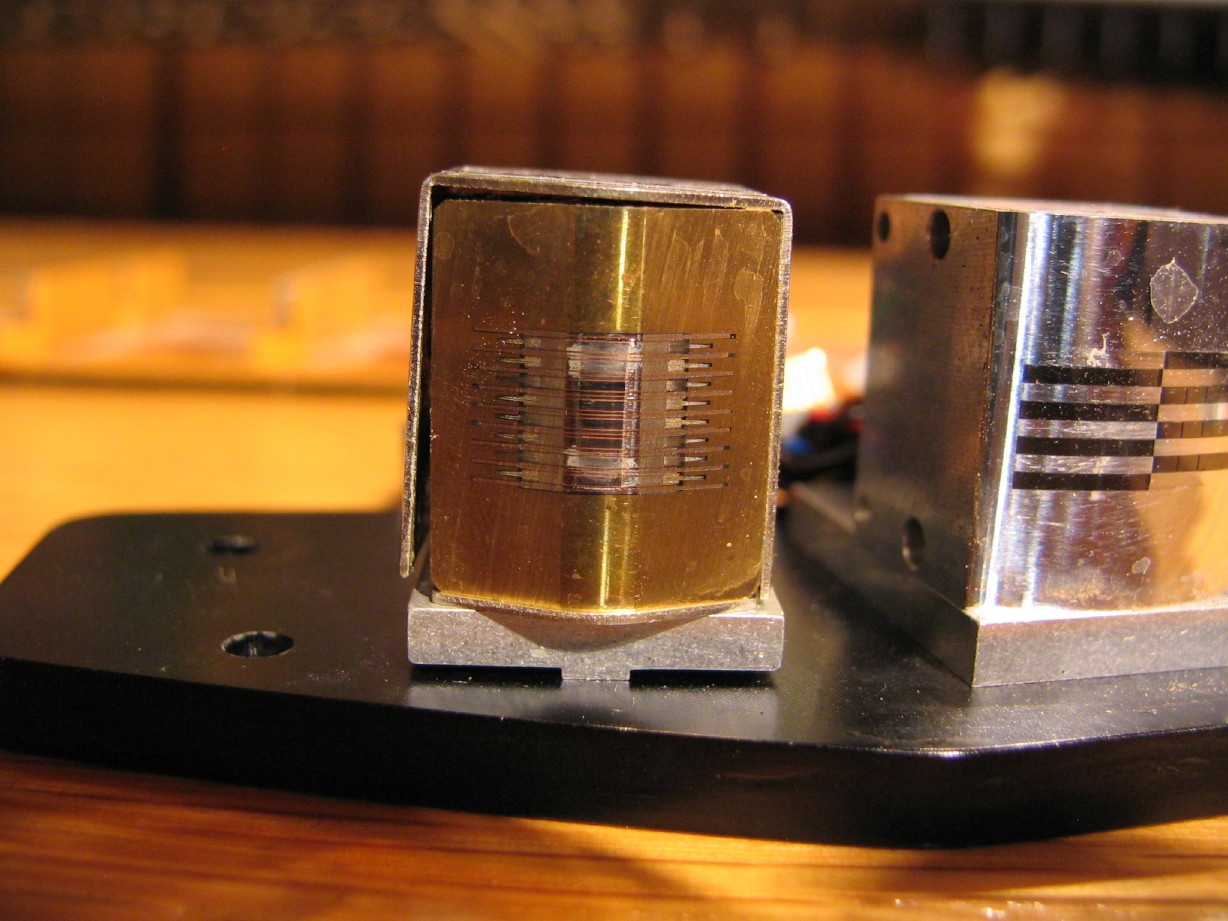

Ethan took careful consideration of the fact that 388 heads are rare and therefore removed as little material as possible. In fact you can just

barely see the remnant of the old wear groove...you can't feel it, but you can see it, just barely. He took it down

just as far as it needed to go. His quantitative perception is that there is a relatively healthy amount of material on these heads when new and both appeared to have quite a bit left so that's great news.

Anyway, big disclaimer here, Ethan is not in the business of relapping heads. If he decides otherwise at some point I'm sure he'll let us know. This was a private transaction between two enthusiasts located in close geographic proximity. Ethan's hope is that these case studies will encourage others to give it a try. Please refer to

his thread on relapping heads...remember he dove in using the Nortronics guide linked in that thread and gave it a try and put the thread up as a resource for others to try. I know I'm definitely going to be giving it a shot at some point, I'm just in a position that I wanted expediency on these heads and I want to experiment on some throw away heads first and I haven't the time resource at the moment...its a priority to have the these heads done, but it can't be a priority for me to learn at the moment. So, thank you Ethan for being willing to engage in the transaction, and even moreso for being willing to dive into this area of DIY and encourage others.

My assessment is that if you have a keen eye, and a relatively steady hand and you enjoy patient crafting then you have the aptitude to do this yourself. The whole crown-jewel of DIY is having the power to take care of your own needs as they arise...having control of the quality and the cost. Relapping is arguably a pinnacle of analog tape recorder maintenance and repair,

but you can do it. It isn't magic. Yes, the well-known firms that do this work professionally have expertise in this field that I certainly can't match...its called time and experience...yes they have tools and facilities to ensure repeatable quality control and to backup their gaurantee. Nobody is trying to say they aren't worth the expense or that there isn't a good reason they charge what they charge...you bet there is, and not everybody is going to be willing to rub their precious tape heads on sandpaper!

But for some it will be worth spending $20 on a half-dozen old tape scanner heads on eBay or something for practice, and maybe $20 in supplies and maybe another $20 in some basic tools to be able to learn and have the gear to relap a bunch of heads.

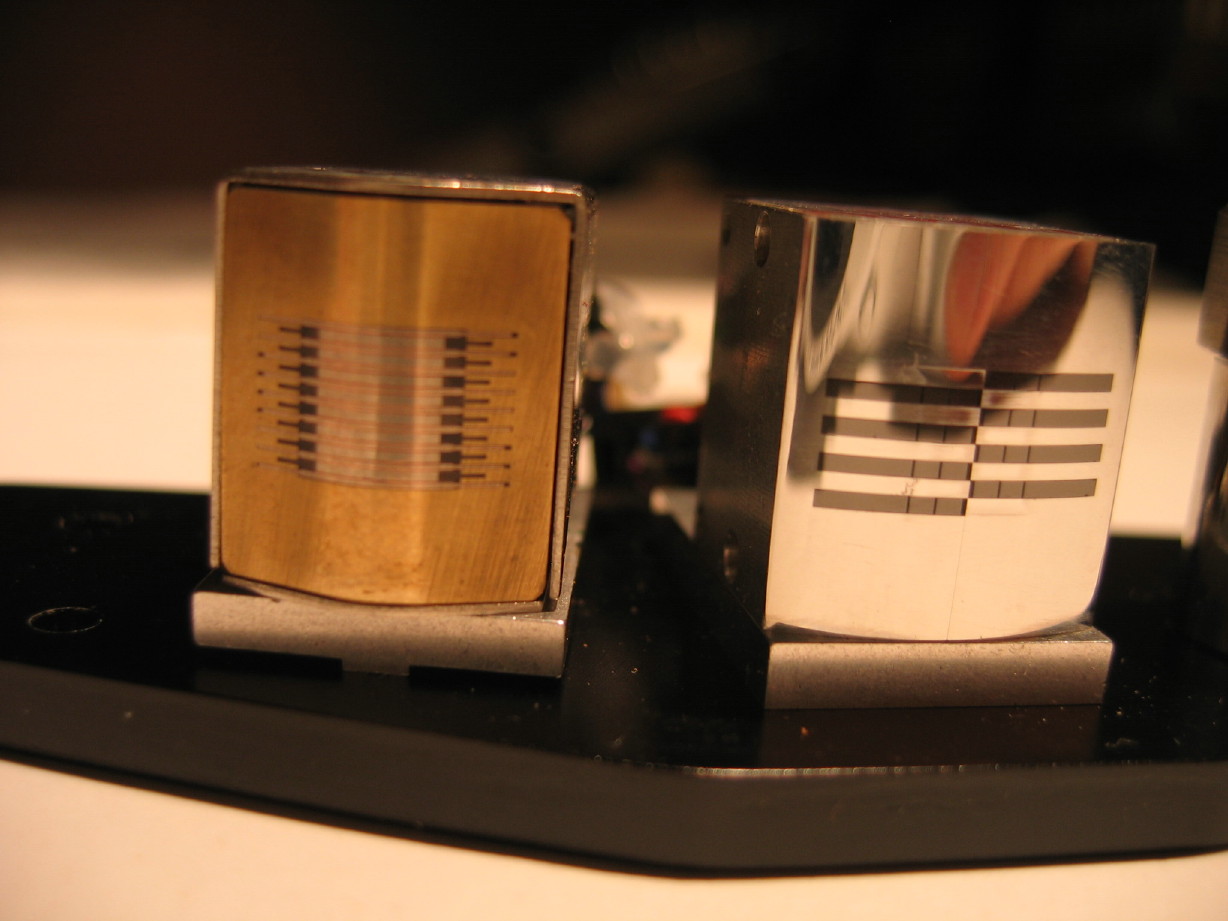

Okay...here's some pictures of the original block...note that these pictures all came out kind of blurry...

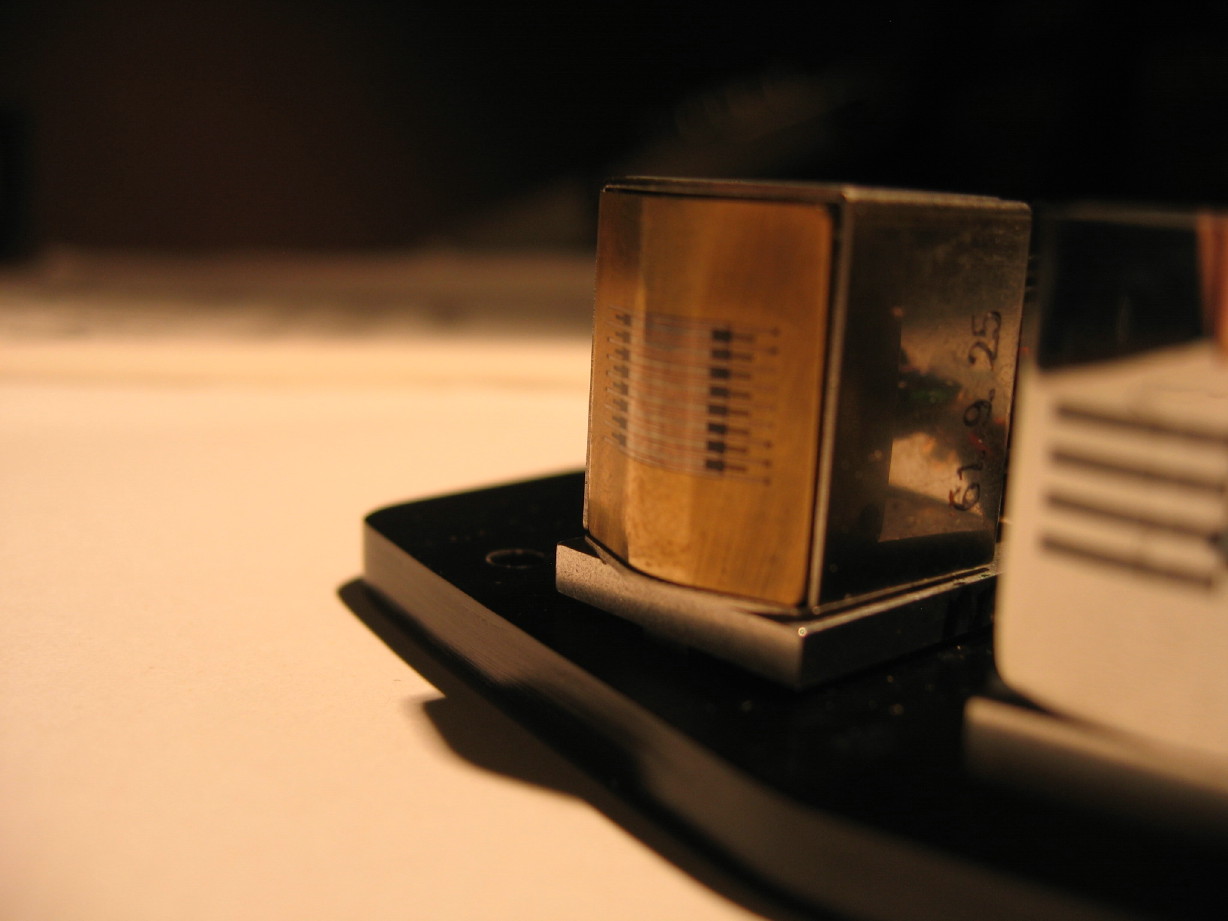

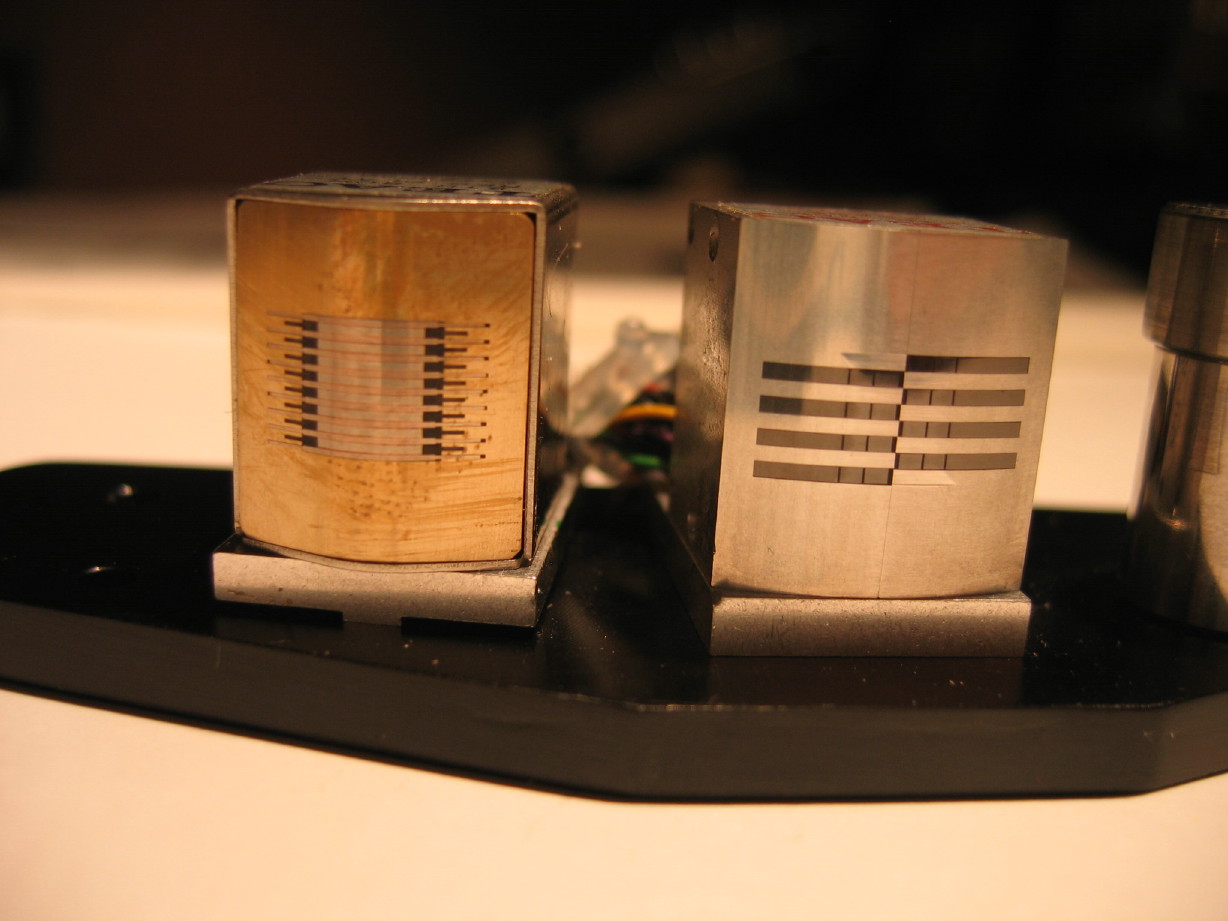

And here's a before shot:

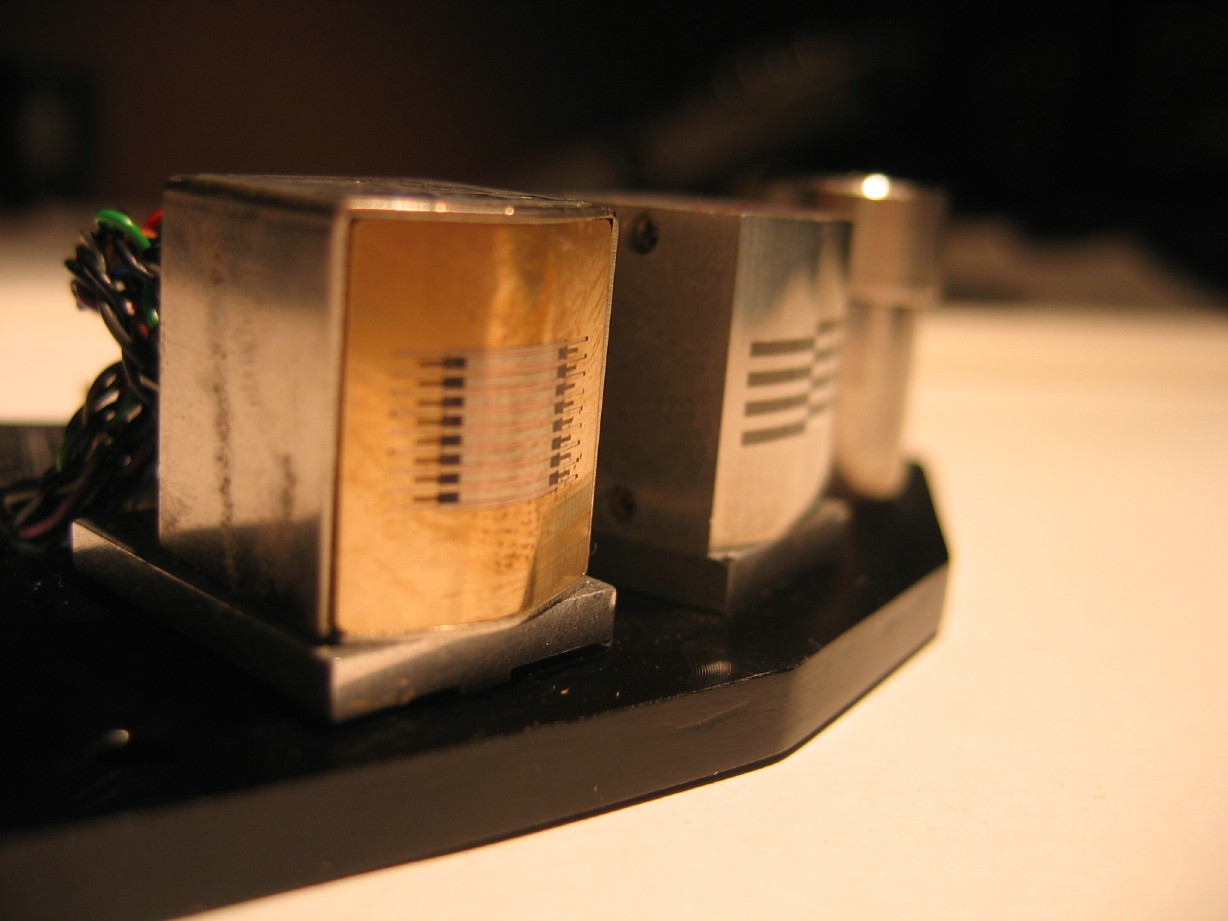

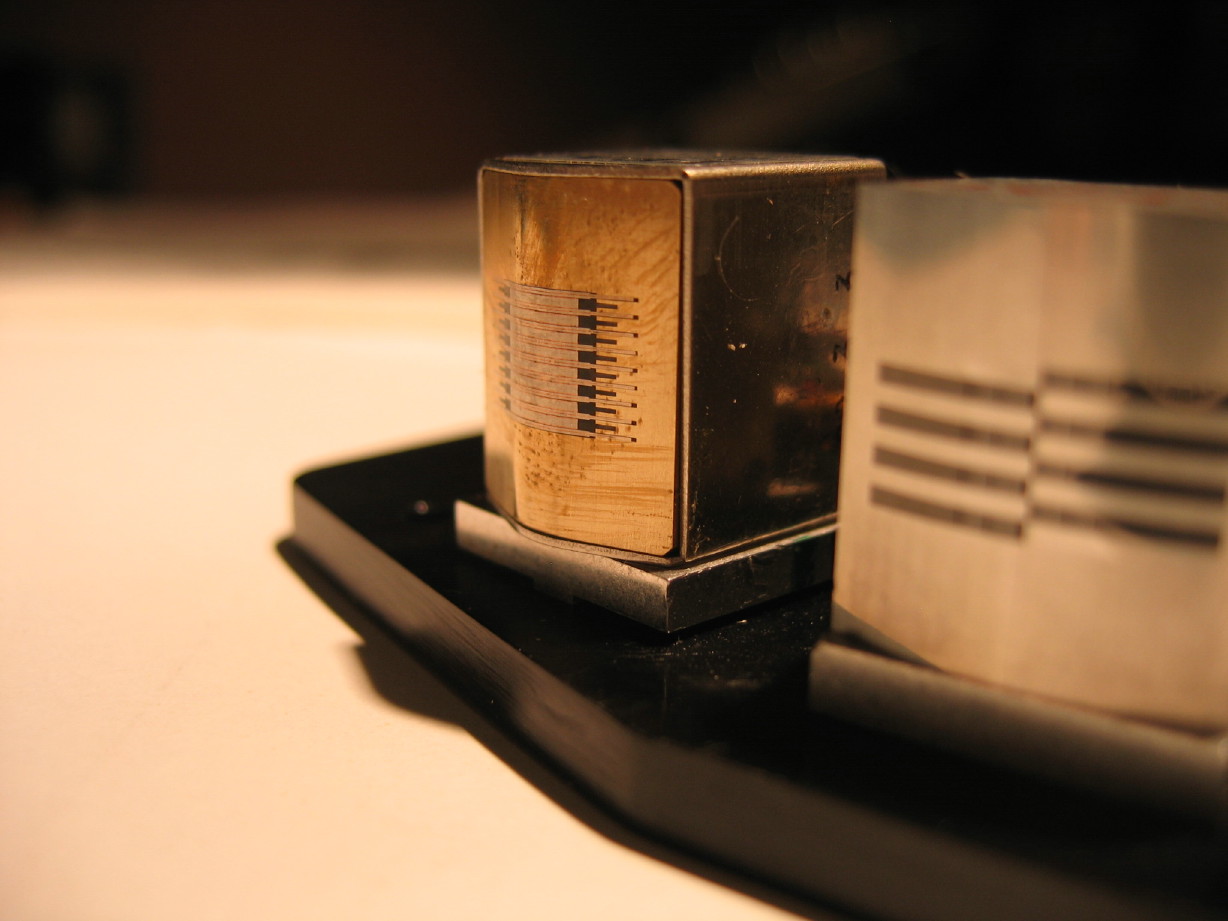

And now for some pics of the spare block...and these are kinda blurry too, and note that the wierd lines all over the face of the stack just remind me I need to wipe it with alcohol...they're not from the lapping process:

Annnnnd the before shot:

Now...not sure when I'm going to get to it exactly, but the next step is to get back to setting this 388 up...never checked the tensions and I'll need to start over on calibrating the electronics with a relapped head in there. When I get to biasing I'll do it using my scope as advised by the folks at Tascam and then I'll report where that leaves the bias amp output voltage at so those of you without scopes using LPR35 can get your 388's in pretty close range for proper biasing of that tape as the 150mV spec'ed in the manual is likely not right for LPR35. Should work good for 457, but not LPR35.