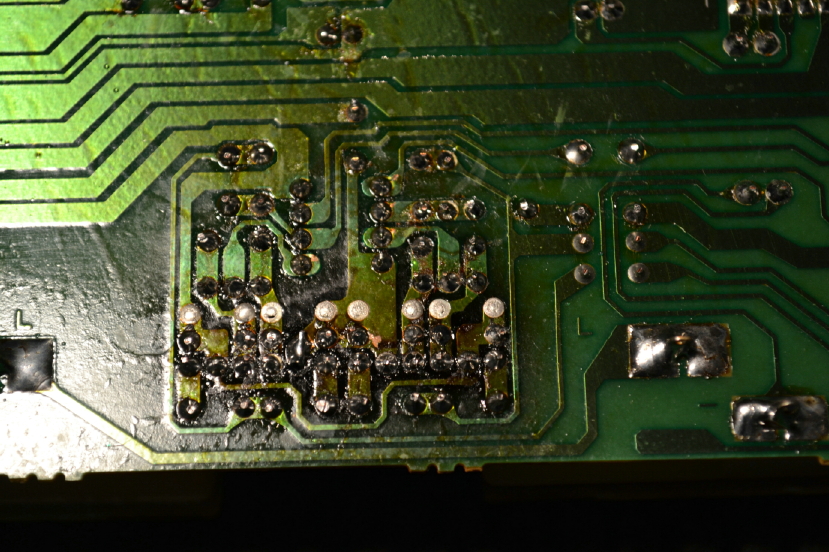

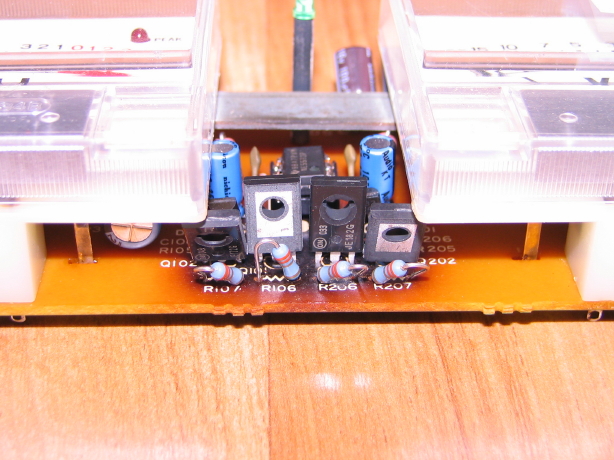

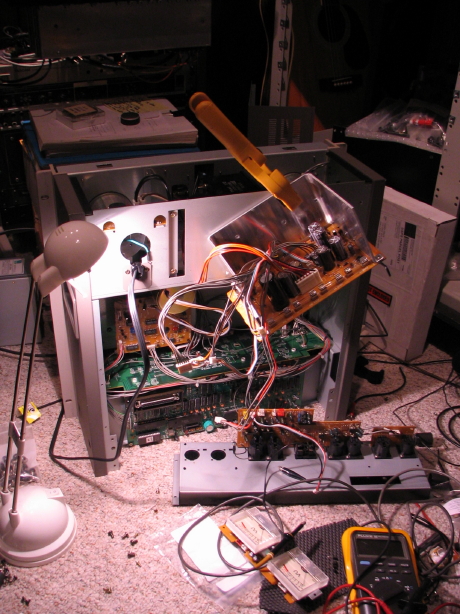

So we left off with a grumbly/noisy left channel in sync and repro mode and high noise floor/hum across both channels IIRC...PLUS the headphone amp wasn't working...this was after the headphone amp was rebuilt because the output transistors looked to have spent a long time at high temps...recapped it, replaced the transistors and associated resistors, did some trace repair on the board and socketed and upgraded the opamp...the transistors that were recommended and which I got were the wrong pinout and killed the headphone amp power rail upon installation. This was clearly my error...a rookie mistake. Recapped the entire power supply, still no-go, sent headphone amp to friend to verify operation and it was A-OK so something wrong with PSU, plus all the audio noise problems still existed. Frustrated, the BR-20T sat for months and months and months.

Finally decided I needed to do *something* so I tracked Ethan down and we decided it would be easiest for me to just leave the machine with him...Ethan being a super-busy fella, and me having no active need for the machine, it rested at Ethan's place for awhile, but I wanted to report an abridged version here what Ethan found and did for the sake of the "Story":

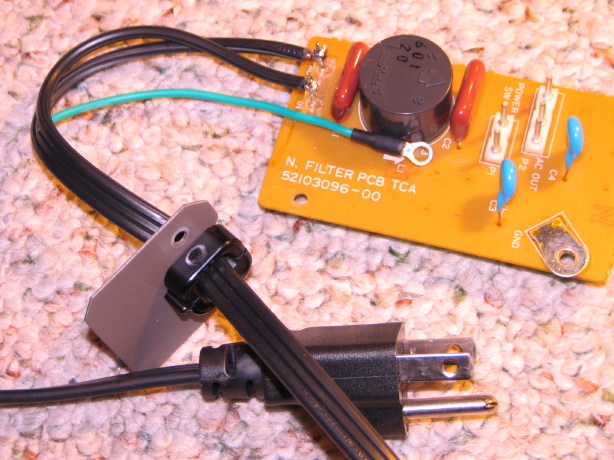

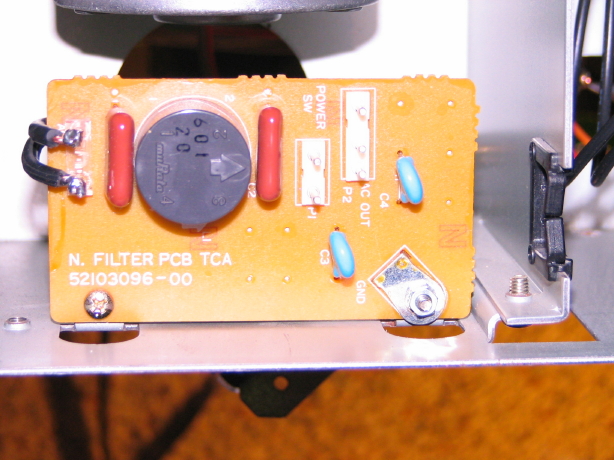

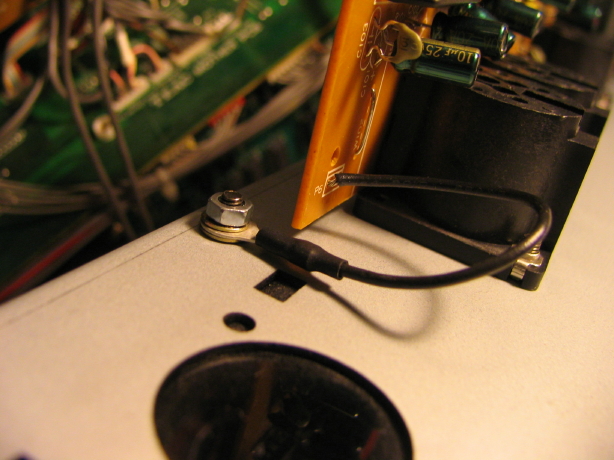

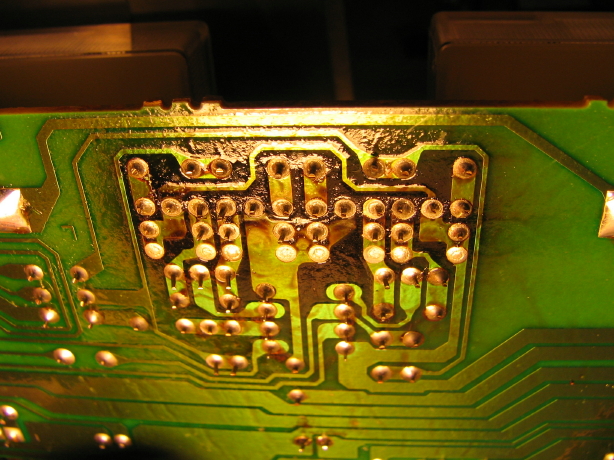

"The [headphone amp] fix: the headphone amp [gpower supply] was blown open [i.e. the current limiting resistors in the power supply had failed open...presumably when I installed the amp board with the incorrect transistors which likely caused the PSU to go WOT...that's Wide Open Throttle for you non-motorcyclists.

This makes perfect sense. I was confused in that I was measuring correct voltage from the PSU with the amp board disconnected, but when connected the voltages would quickly be pulled to 0V...and it changed over time, got worse...so I'm thinking the resistors were toast and power had found some high-resistance path either through the "open" resistors or by some other means, but regardless was "toast".]

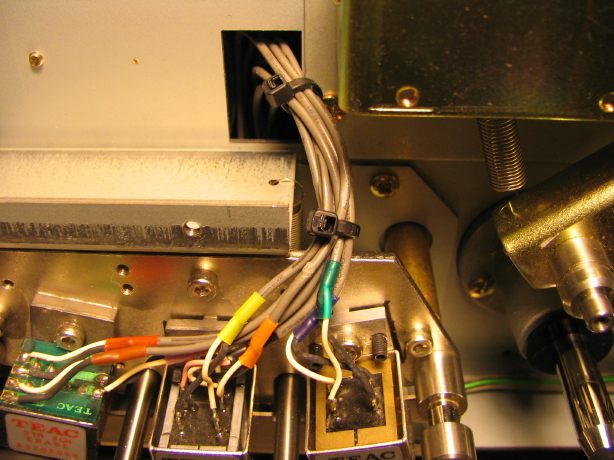

As for the noise: I chased signals around for a while and like you noted that it did not follow the rec/play amp boards when swapped. I did change the ch1/ch2 head wiring and the noise stayed with channel 1. This eliminated the head as a problem. Then I pulled the sync connection from the motherboard which allowed ch1 to be quiet for a few seconds then the buzz came back. Also I had shorted the ch1 sync inputs which silenced the noise (shorted input should be quiet).

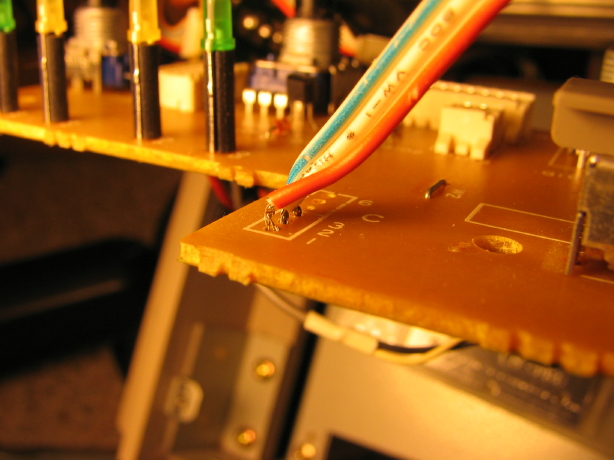

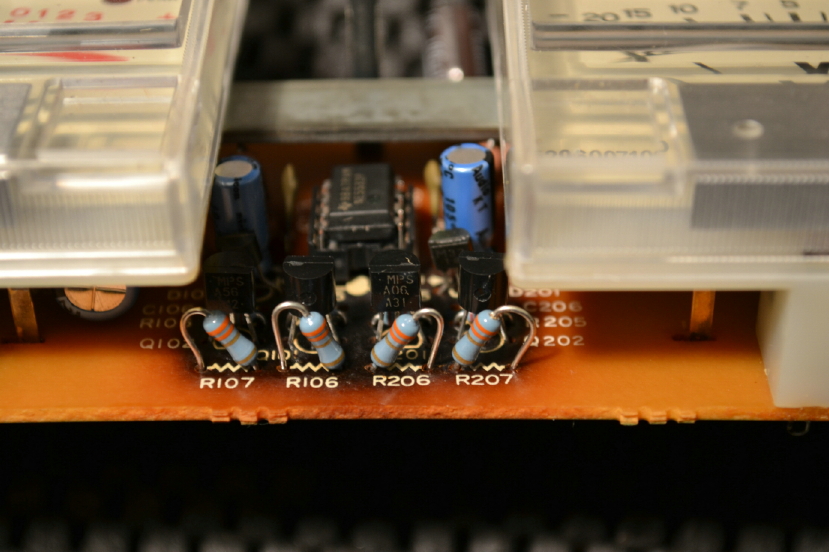

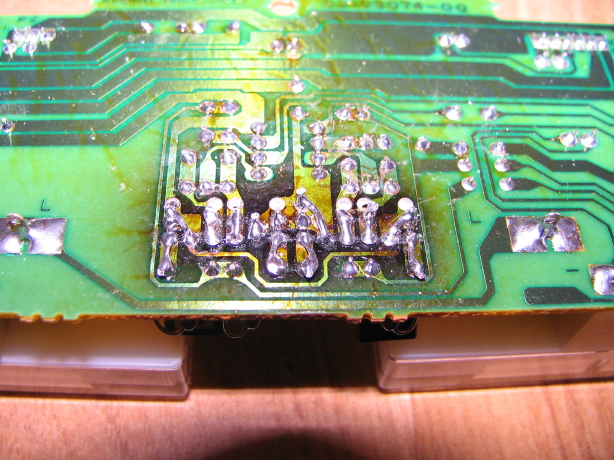

This really left the motherboard as the single thing common. I was loath to remove the motherboard and did touch up the connectors with a little solder just in case there was a crack. No change. Then looking over the manual I see that the sync head outputs go to the time code board. So I start tracing those wires.

Remember how with the head disconnected the output was quiet for a little while? Something like that takes a cap to charge up to get the time constant. Having the sync heads go to the time code board might give such a cap. And one channel could be bad and the other fine with something like this...when looking at the machine something was not right so off again to the manual and

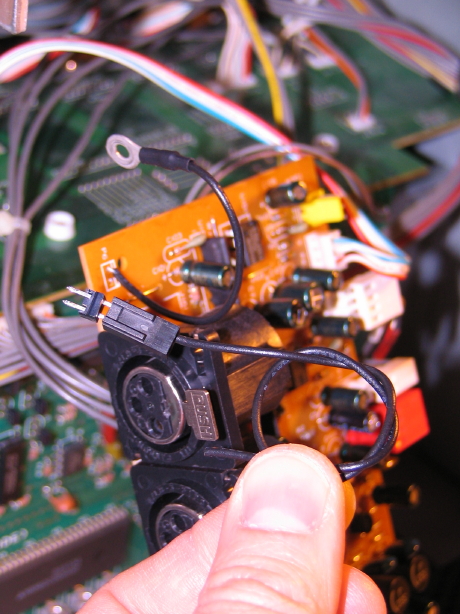

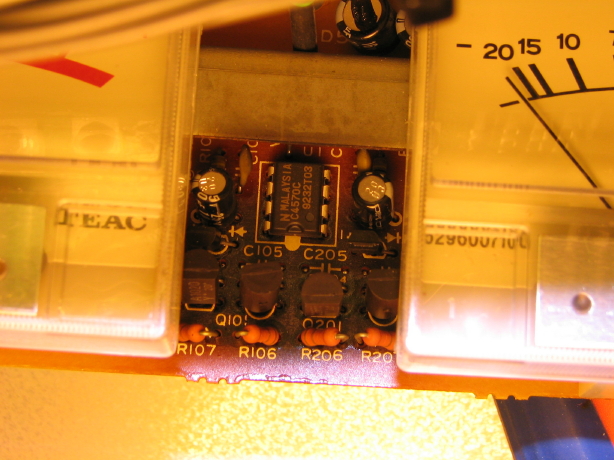

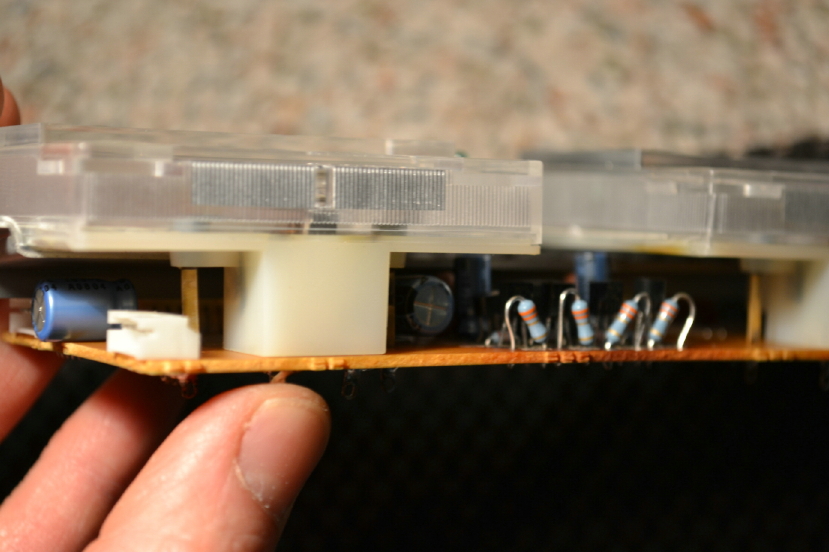

I discovered that the time code and bias/amp board were swapped. [yours truly is STILL slapping forehead and shaking head...] They were in each other's slots. Lucky that Tascam made it so they would not fry in this case but sad that they made it so that it was possible.

Putting both boards in their respective slots and the noise is gone, The deck records and does not have the distortion caused by the lack of bias...good news."

Indeed.

So me swapping the boards goes back quite a ways because I sequentially removed those boards as a troubleshooting step AFTER the problem was evident, meaning I must have swapped them during the cleaning stage. But I KNOW I was careful upon reinstallation. I betcha when I have the machine back in my possession it'll be evident what I did...I have a hunch I was referencing something upside-down. At any rate, it IS surprising that the cards would be able to fit in each other's slots...and VERY fortunate something else didn't fry, at least nothing that's known yet.

But Ethan

has done a basic play calibration and so far it is doing well.

Ethan was kind enough to send additional detail of his troubleshooting path relative to the schematics which is handy as a case-study then for future repair needs I may encounter.

Thank you, Ethan!

Should be able to go pick the BR-20T up in a week or so, give or take.

This makes perfect sense. I was confused in that I was measuring correct voltage from the PSU with the amp board disconnected, but when connected the voltages would quickly be pulled to 0V...and it changed over time, got worse...so I'm thinking the resistors were toast and power had found some high-resistance path either through the "open" resistors or by some other means, but regardless was "toast".]

This makes perfect sense. I was confused in that I was measuring correct voltage from the PSU with the amp board disconnected, but when connected the voltages would quickly be pulled to 0V...and it changed over time, got worse...so I'm thinking the resistors were toast and power had found some high-resistance path either through the "open" resistors or by some other means, but regardless was "toast".] But Ethan has done a basic play calibration and so far it is doing well.

But Ethan has done a basic play calibration and so far it is doing well.