Vintage Texas

New member

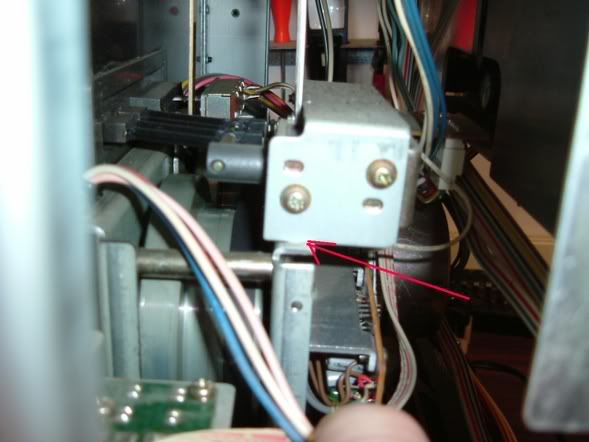

Carefully lower the whole plate down in a angle between the bottom section and upper pc-board and unplug the plastic connection plug for capstan-motor supply board:

Now the belt can be reached that probably is stretched or broken:

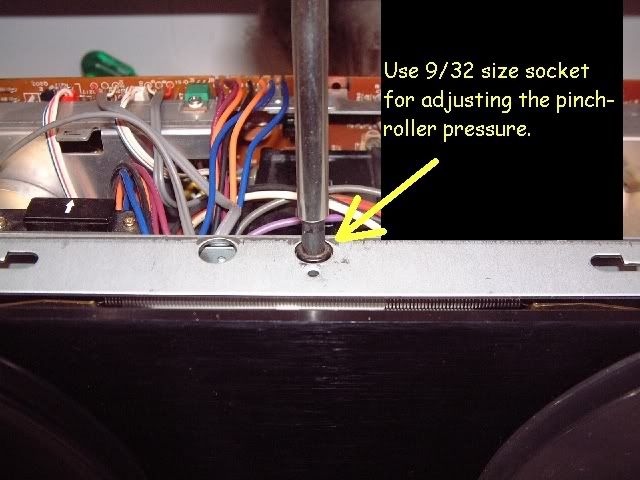

Both fly-wheels need to be taken off to reach the linkage controlling pinch-roller engagement that usually is gummed up and doesn't move properly when pressing play-mode.

Take the head-cover off the front and you find a black plastic washer on the shaft on each capstan-arm, pry carefully off this washer and slide the Left fly-wheel out from the back at the same time, don't loose that washer now.

See red arrow:

Here is the L-flywheel with plastic washer next to it + old gummy belt:

Now the belt can be reached that probably is stretched or broken:

Both fly-wheels need to be taken off to reach the linkage controlling pinch-roller engagement that usually is gummed up and doesn't move properly when pressing play-mode.

Take the head-cover off the front and you find a black plastic washer on the shaft on each capstan-arm, pry carefully off this washer and slide the Left fly-wheel out from the back at the same time, don't loose that washer now.

See red arrow:

Here is the L-flywheel with plastic washer next to it + old gummy belt: