T

The Great Cobb

New member

ok

Sorry, double post.

Sorry, double post.

Close enough to be the same. Odd.

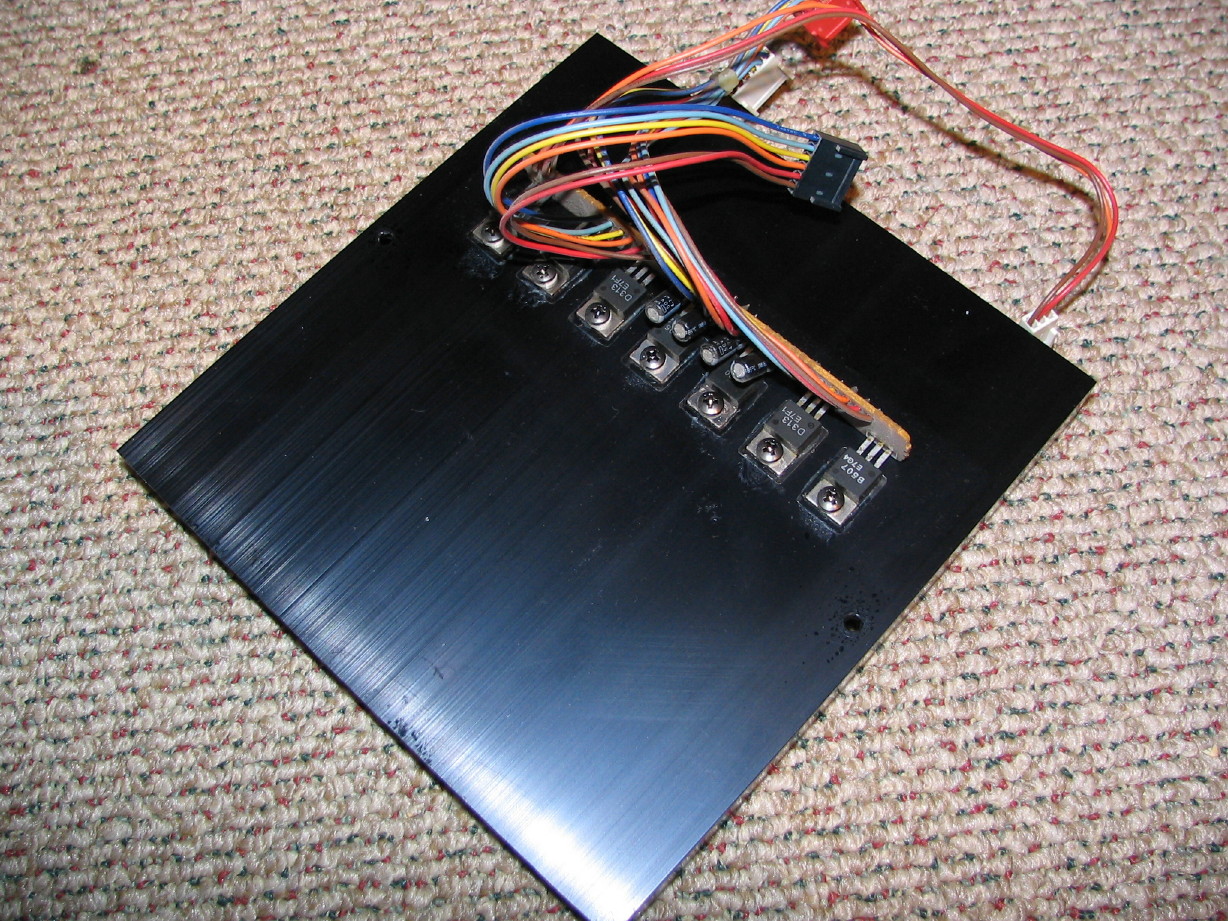

Does it appear the the series pass transistors get hotter than the heatsink (much hotter that is) - Be aware that the transistor cases are likely at unregulated voltage levels so don't touch them with the power on and don't touch them with a pad of your finger least you want to get burnt. (Use the top of your finger at the first joint).

It does not appear that we have an overload based ont he current readings. So now I'm thinking about a lack of heatsink grease on the series pass transistors that leads to thermal runaway.

--Ethan

OK if the transistors and the heatsink are the same temp then we (should) have good thermal conductivity.

You might try this where you don't let the heatsink get fully hot - just let it start to get hot and then test the transistors to see if they are much hotter.

Thermal runaway does involve changes in values as the part(s) heat up.

When you measured the currents did you let it run for a while? We are looking for the thing that takes more than its normal share.

Quite a stumper.

--Ethan