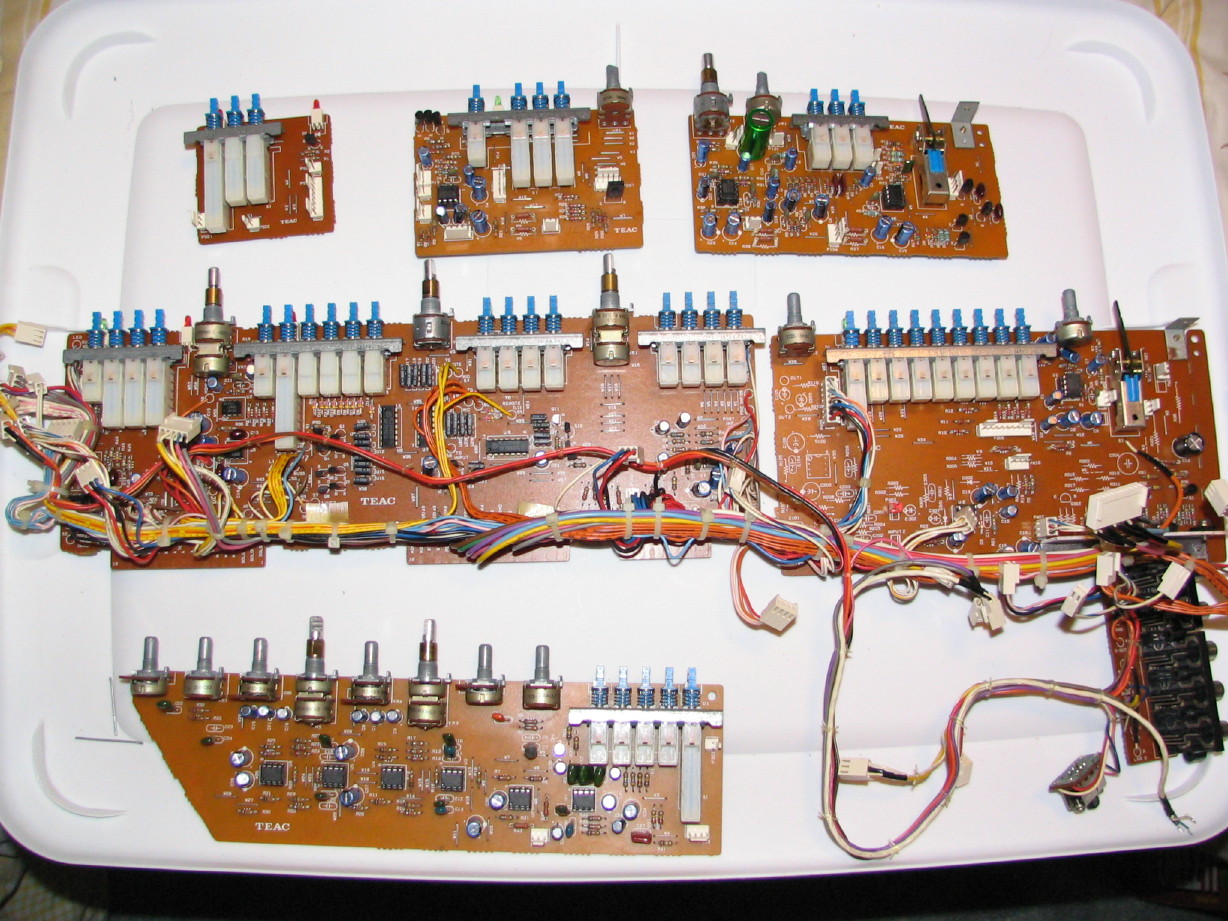

So, okay...I was thinking I could flexibly reconfigure the jack sets in these 72-point blocks, but, duh, we can all see that there is a single cast part that contacts the shell of each column of 3 jacks...so, so much for that. But it should STILL work out pretty nice even if there isn't a lot of room for labeling and I'll probably just keep a cheat-sheet handy, and, really, the layout is going to be so logical anyway...the buss outputs will be normalled to the tape machine inputs and right below that will be the non-normalled jacks connected to tie lines to the DAW inputs...that's the first module. Then the next module is the tape returns normalled to the tape machine outputs, and right below that the non-normalled jacks connected to the tie lines to the DAW outputs. Then below that will be an insert I/O module, and the send jacks are normalled to the return jacks and *right* below those will be a set of non-mormalled jacks connected to tie lines to processing gear. Lastly is the module with all the master section I/O and there is a host of outputs and inputs there that are normalled and below that a set of non-normalled extra tie line jacks available for...whatever. Makes sense to me...which...is...uh...sensible...to me.

ANYway...

I got the custom patchbay module faceplates back from Front Panel Express and boy am I pleased with them...my measurments were quite correct. They fit on the jack blocks like they were absolutely meant to be there, and they look nice. They did a nice job.

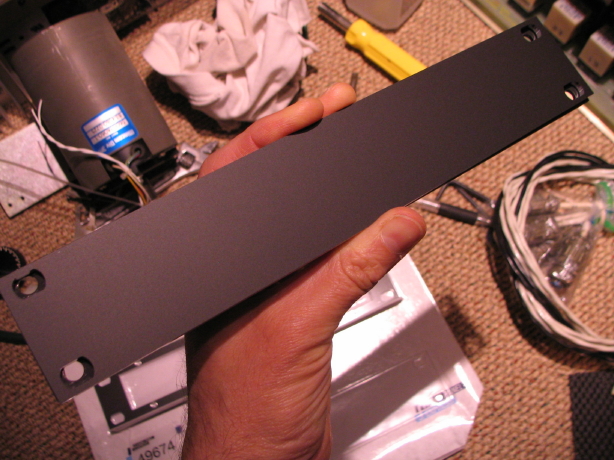

Here is what you pull out of the package when it comes...they spare no expense to make sure that the plates don't get scratched up:

I got my plates a little thicker than stock. You can't hardly tell the difference from the front, and I figured for a few extra bucks it was worth the additional rigidity. Shiny edge is new plate, black edge is stock:

Here is the single blank plate I had made up and the stock plate is behind it...they are exactly the same size and the rack-mount holes are right smack where they ought to be:

Here is a new plate mounted up to one of the jack blocks:

And for comparison here is the stock module with the new one:

And who could resist doing a mock mounting of the new module in the (filthy) console frame? Not me.

SO...

I can check "obtain missing patchbay modules" off the JH-416A project list. All I need now is a whole MESS of install wire...and a bunch of time, patience, and SOLDER!! I won't be getting to that phase anytime soon, but that's all that's left to resolve the nasty stock punchblocks, missing harnessing and missing patchbay modules.

ALSO...I now have a full set of (formerly) unobtanium JH-416A schematics which is an extreme plus for me.