I'm doing some work on the patchbay element of this project.

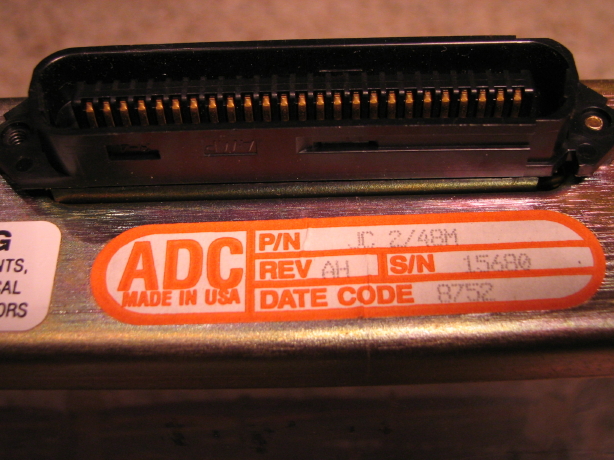

I'm finalizing the design of the custom mini-rack panels that will be fabricated by Front Panel Express that will mount the ADC TT jack blocks...just making sure my design is right before I pull the trigger and place the order.

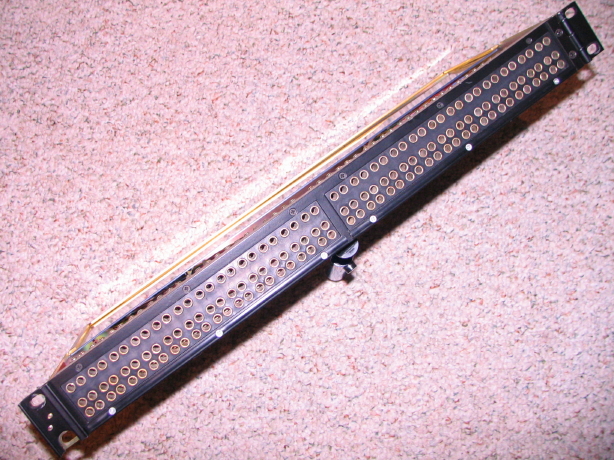

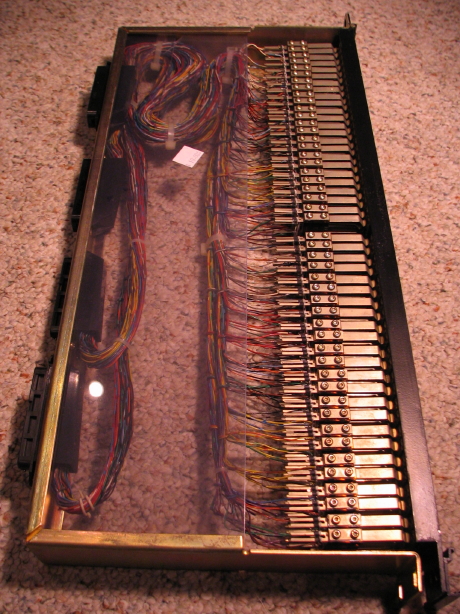

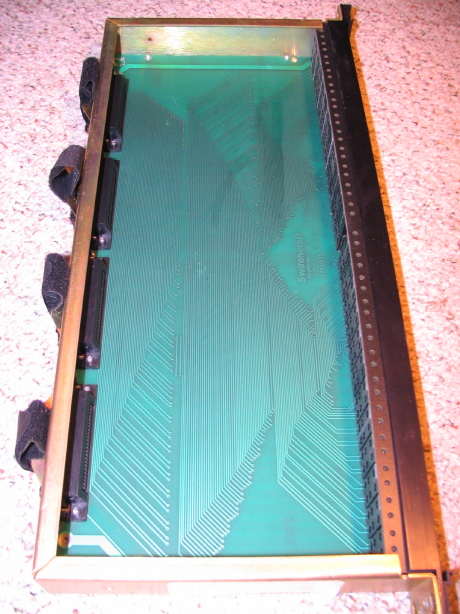

The ADC patchbay featured in my last post has been disassembled (removed the jack blocks from the frame) and I've stripped all the wire-wrap wiring from both blocks. That's nearly 400 little wires to unwrap from each 1U bay.

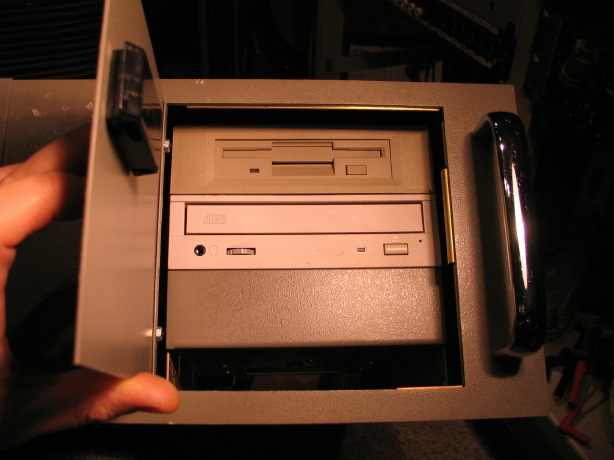

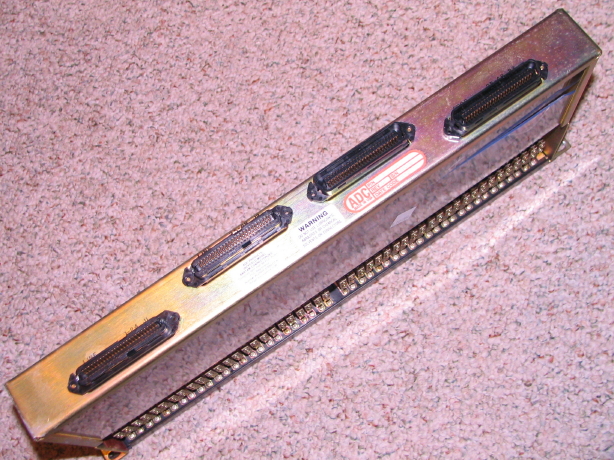

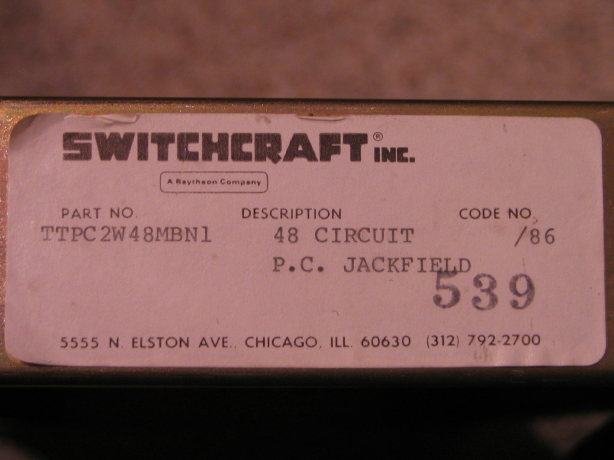

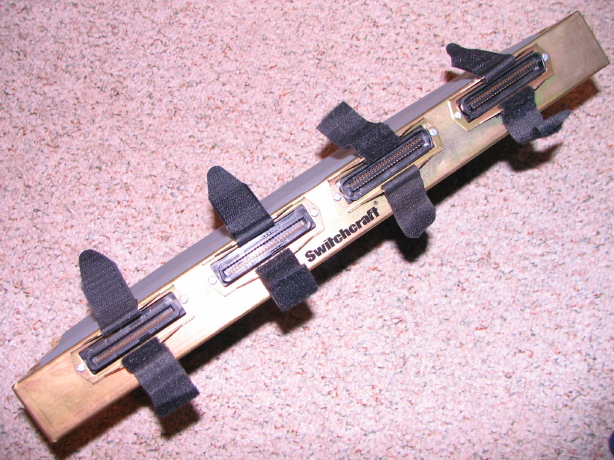

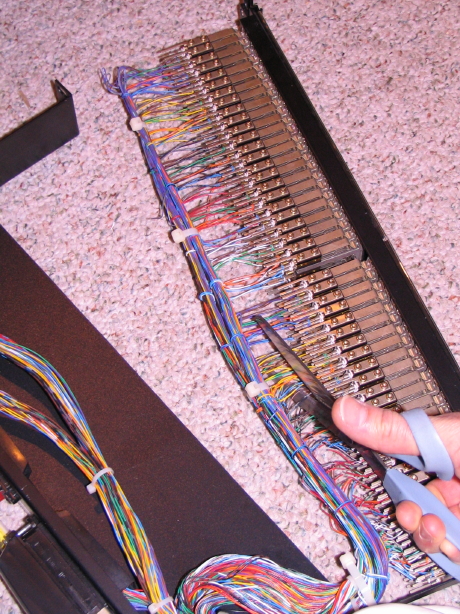

I just unboxed another identical but even newer ADC bay I got for cheap sometime last year to do the same thing. I'm stoked. My JH-416A will be outfitted with a basically new patchfield. These are nice bays. So nice that it totally feels wrong to do this:

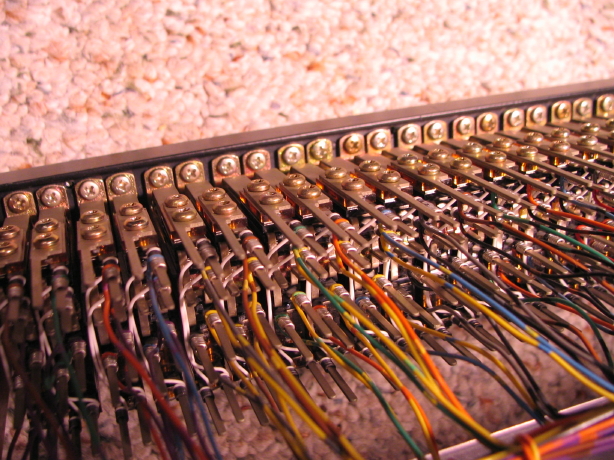

I believe this particular unit is essentially unused and there I am hacking into it with a pair of scissors. I have to remind myself that the wire and wire wrapping in general is not ideal for audio. The wiring is, like, 28AWG or smaller solid core CAT3 telco wire, and eventually the wire wrapped on the jack terminals can oxidize and cause trouble. That's why I'm yanking all the CAT3 and when it comes time to build up the harnessing I'll be soldering everything and using Gepco 22AWG shielded stranded install cable.

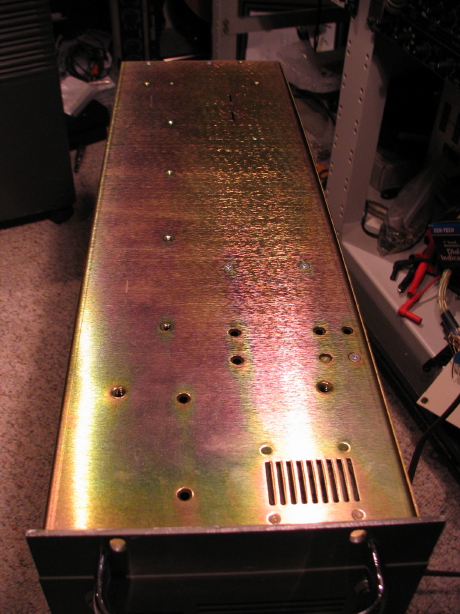

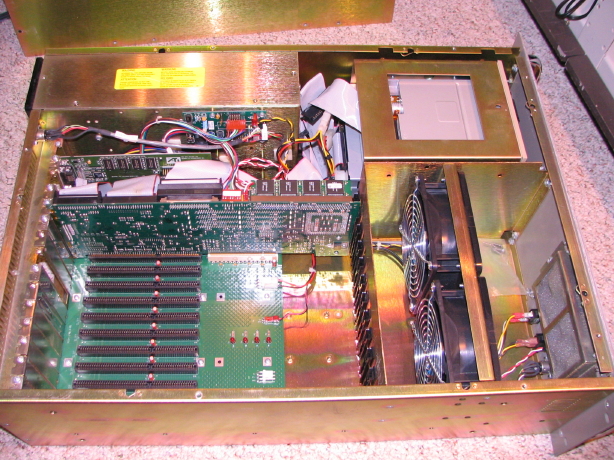

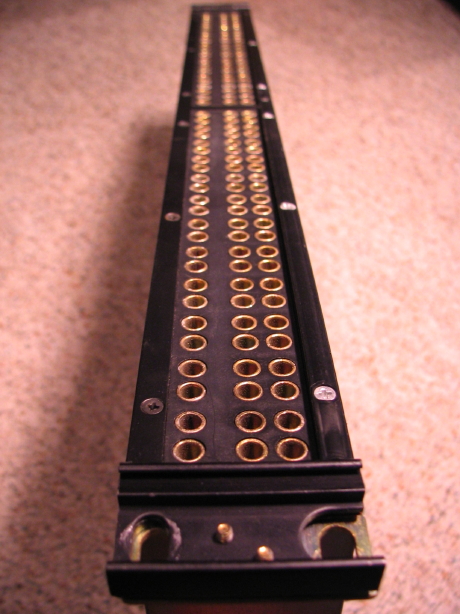

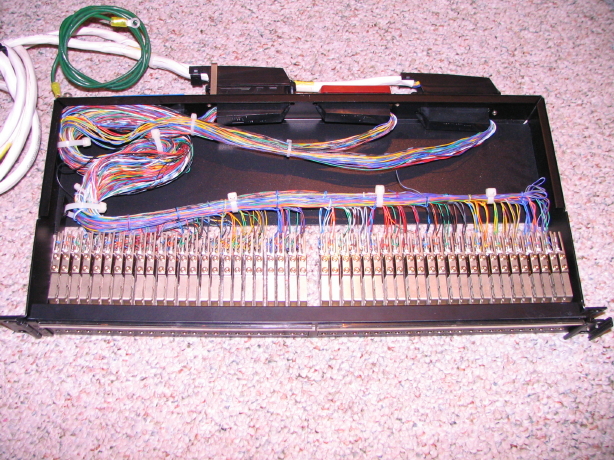

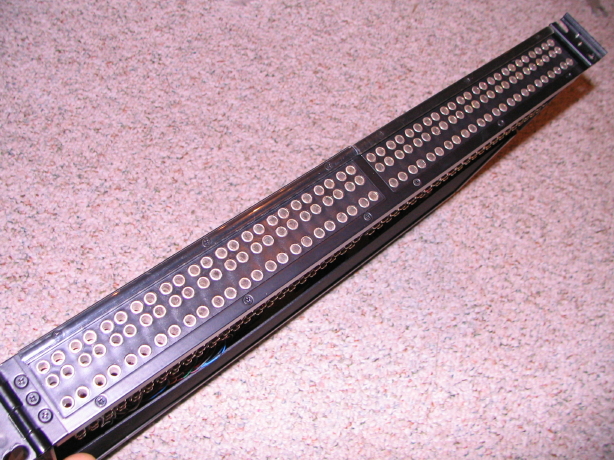

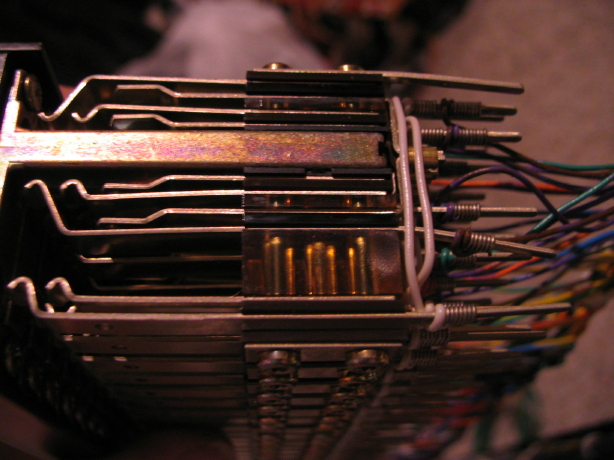

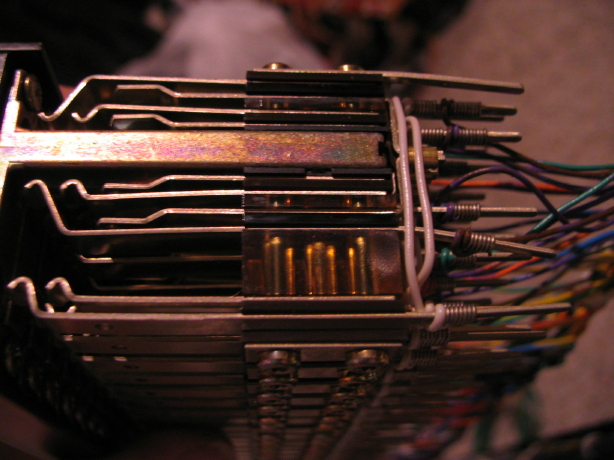

Here's a few more shots of this most recent patchbay:

The contacts are heavy guage. The insulators are, like, resin or something, not phenolic board.

So, again, the JH-416A mixers utilize 5 1U half-width patchbay modules. The factory configuration is 240 points total, 48 points per module. The JH-416B mixers utilize 6 modules for a total of 288 points which could be advantageous if you have a 16+ track tape machine as well as a DAW that's getting tied into the patchfield. The factory modules (which, again, are also made by ADC) are configured as 2 x 24...2 rows of 24 jacks in 2 separate jacks blocks. When I started picking up used ADC patchbays they were all single jack blocks of 2 x 24 jacks...same jack count but squeezed closer together and normalled. I figured that was fine because the first 3 modules normalled anyway on the 416 mixers. Then I started finding the jack blocks with 72 points...3 rows of 24 jacks, 2 rows normalled and the 3rd row doubling the first. When all the wires are removed the first 2 rows are still fully normalled and the 3rd row is independent which is great for the tie lines where non-normalled sources connect. So I have a total of 4 of these 72 point blocks that are in, like, new condition. So I'm thinking of just using the 4 blocks and having 4 modules with a blank for the 5th bay. That would still give me 288 points with the option of adding another 48 points later if needed. The 72 point blocks with 2 normalled rows and a 3rd non-normalled row could actually be really sweet...dense, but practical with room to grow if needed.

And here's another update: I believe I have located a set of the unobtanium JH-416A docs and the owner is kindly allowing me to borrow them and scan them in. I'll keep you posted on that but it would be a real good thing to have a proper set of schematics.

)

)