Cory, glad to see things are coming together with the PSUs and wiring harnesses and moving onto thinking about the module refurbs!

Hey, if you want to talk turkey about re-caps, you know I'm ass-deep in mine! (Hey, i'll trade ya for a lesson in grounding schemes!

) In the end my re-cap plan was a balancing act of "how can I keep this affordable while improving value where possible/prudent/cost-effective. In your case, with many fewer caps to order and probably a more generous budget (I'm perpetually shoestring), you sure have options I didn't but anyway....Nichicon and Panasonic are both very good choices. I wound up with 99% Panasonics as it's what suited my needs. Yes this meant that the bipolars are 85C caps and that's kind of a bummer, but in the end I resolved that it's not that huge a deal, either way, this is probably the last re-cap this console will get and they'll last a good long time. Would I have popped for Nichicon Muse bipolars if I had the budget and the stocks of the values I wanted were available? Very possible, but not how the cookie crumbled. If I'd had more time and a bigger budget, I would have spent more time working up a scheme that was all about performance and weighed each and every cap's purpose in its place in the circuit (especially the BPs as they're mostly in the signal) but...needs must, oh well!

For polar caps I wound up with Panasonic FM, FC, and due to available stocks in the large quantities I required in the time frame I needed them, I actually ended up ordering quit a few NHG and FR series, the latter mainly filtering IC power pins. They spec similarly to FM/FC and the price to quality ratio is very good. All of the polars are 105C caps.

Probably the only place where I was feeling iffy about using 85C (bipolar) caps was in the EQ sections, because in my console that's where lots of heat gets trapped an indeed where I experienced the highest concentrations of old cap failures. In your 416, the modules aren't nearly as cluttered with daughtercards and the main boards aren't as heavily stuffed so probably better ventilated, but then, I don't know, maybe it also runs warmer than a 600 series?

But I ramble...really glad to see the progress on this console!

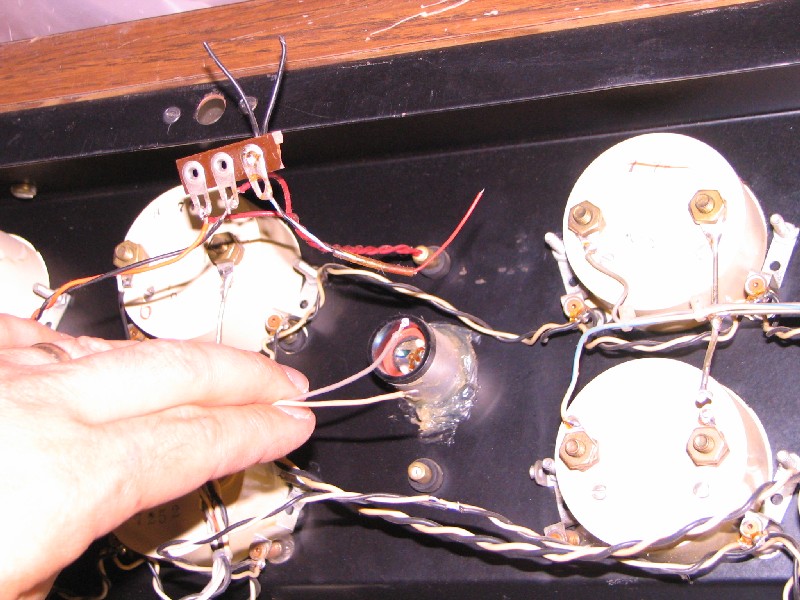

Brian, I think the 400 series DO run warmer. My impression of some of the scuttlebutt about opamp failures over the years is that they are related to heat. I'll have to see once I start using mine whether heat buildup is an issue and if it is I may add some forced air cooling to the frame. It would be easy to do. The entire bottom of the frame has a perforated screen that runs along the entire width and is about 10~12" deep underneath the motherboard, and there is also a perforated strip just below the armrest. The way it is designed it appears that air moving in a convection pattern would come up from under the motherboard at the front edge and also through the vented section below the armrest and then up and toward the back along the module cards and vent out the perforated section on the BACK of the frame, which also runs the entire width. You can see the rear perforated section and the one below the armrest as well as the gap between the frame and the front edge of the motherboard in

this picture. Decent design in theory but I'll have to see if stuff is getting significantly warm and in that case then some baffling and placement of a couple-three fans at the back that are low rpm (i.e. quiet) would probably take care of the problem just to encourage some air-flow.

I think more than anything ensuring good heat-sinking for the opamp TO-99 cans will be important. A bunch of the cans in mine have nothing, some have the standard steel finned heat dispersion bands and a few have these really cool extruded aluminum heatsinks. I'm trying to determine if the there is any benefit in the aluminum ones and if so I'll probably stock up on those. They are like

these. Also, of course using a good heatsink compound. I'm a bit bothered by what somebody did in the past on mine...there are a bunch of the TO-99 cans with the steel finned type bands that are GLUED on with some sort of silicon product...the steel bands don't seem to fit tight (also a problem in and of itself as far as cooling goes) like they do on the ones in my Ampex MM-1000 amp cards, so to remedy the issue they just blobbed on some kind of caulk. Seems to me this could do nothing but harm to have a cap of insulating silicon rubber on top of the can.

So I'll get those cleaned up for sure.

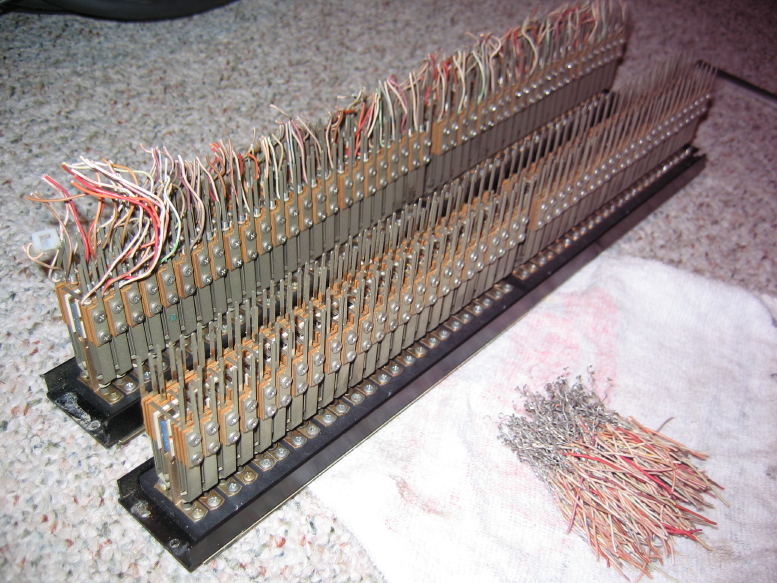

Caps...yeah...the JH-416"A" cards are really VERY simple...only two kinds of electrolytic caps, the 100uF coupling caps and only a handful at that, and the local filter caps. They seemed TOO simple to me...all sorts of caps I'm used to seeing that just aren't there...I thought it was just because it was older but then I realized its because they are transformer balanced...you add a bunch of stuff when you go transformerless, all in the name of "transparency" I suppose. Anyway that's it for caps...12 coupling caps and 2 filter caps per module. I'm told the factory Ducati caps on mine are known to have not been great from the start and are also known to be prone to premature drying out...I think in this kind of situation pretty much ANY reputable cap is a sure improvement. I use Nichicon because its what's familiar to me and therefore I'm comfortable with them, but honestly I think it really is true that there isn't going to be some "magic" improvement by spending premium on the best of the best of the best. Yeah, I'm sure there are plenty of arguments counter to that statement, but I don't think my ears are goiong to hear the difference you know? I think it is of paramount importance to consider the source and his/her goals when receiving advice. And I also believe it is acurate to say that the "standard-grade" of today is better than the "select-grade" of yesterday, and the stock caps on my cards were

not "select-grade".

MAN I used to do a lot of shotgunning of all electrolytics. Maybe some of it was warranted, maybe not. Maybe it was all just an insurance policy, maybe none. I don't know. I still think its a good practice to recap a power supply when it is getting on in years, but my impression is that its stuff like what I have in my JH-416 that drive the practice of recapping...its about 40 years old, operates warm and the caps weren't that great to start with. It makes clear

sense at this point compared to a lot of the other recapping that I've done on stuff that is about

half the age of the 416 and had better parts from the get-go. So I'll be recapping as I get to it but not before I get it cleaned up and operating. Just don't want to go that route again; work-work-work before play. I've got plenty of work to do on this thing but the goal is to hear how it sounds, and it'll be more fun to hear what it sounds like stock and then hear how it opens up with some new parts. And then like I said above I'll try some different flavors and I have a hunch I'll end up using the Nichicon KT's. I've used scads of them. They are Nichicon's only "audio-grade" cap that is also rated for

105C. I could spend double and triple or more on the MUSE stuff but I just don't believe that the incremental difference is going to be a justification for spending that much more money you know? Its a passive component. A better part is going to do better at staying out of the way of what the active components are doing but I think you reach a point that you are splitting hairs, and they didn't even HAVE stuff like the KT's back in the day. It'll be interesting to try the FG, KZ and ES MUSE caps and do a shootout and see. In the end I think the KT's will be the winner based on the temp rating and cost coupled with the performance (pun not intended).

The decision to go with 220uF over the stock 100uF (which is already pretty good size for coupling) is based on the LF knee calculation. The stock value tapers at between 2 and 3Hz. Sounds like 2Hz is a good target which would call for a 133uF cap so going the next standard value up brings us to 220uF which puts us in the 1Hz area. No high pass filtration going on there which is what we want. Would MCI have put 220uF caps in there from the beginning if they could? Maybe, but in 1970 a 220uF electrolytic was bigger and more expensive than the already big and expensive (relatively speaking) 100uF parts they put in. Money is the great compromiser of audio equipment. The JH-400 series, in spite of being a "professional" product was geared to handily beat the competition on price and so some value engineering was employed. Today it'll cost about $100~$200 to recap. Not bad when you consider that in today's dollars as equipped my console would cost between $150,000 and $200,000.

My point here is that your Panasonics are great parts. Brian you know as well as I do that you can search the web for what people have used and Panasonic parts ALWAYS come up. FM, FC, whatever. Good stuff. If I wasn't so familiar with the Nichicon parts I betcha I'd be putting Panasonics in.

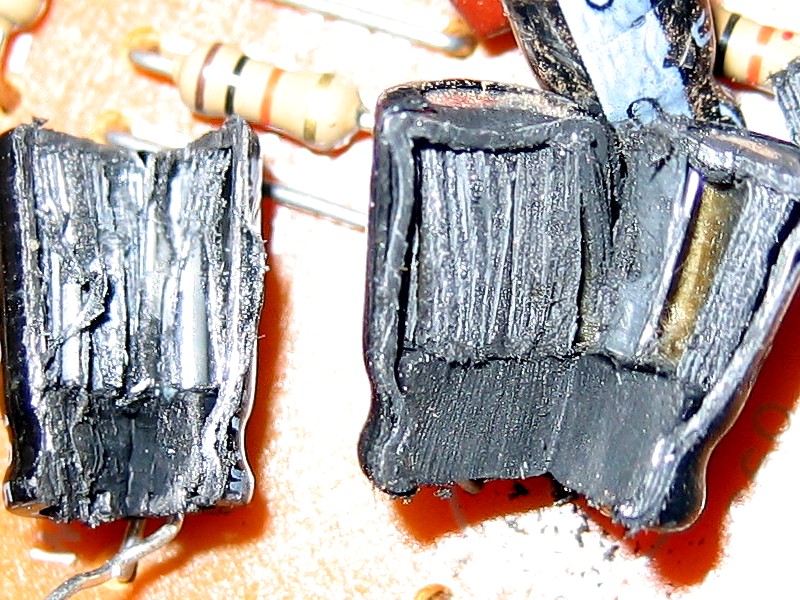

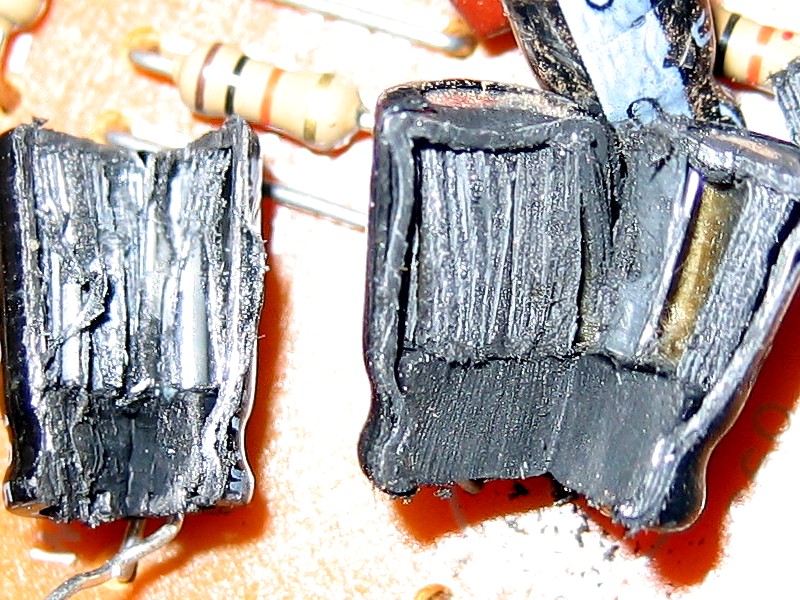

And the whole non-polar vs. polar thing...I wanted to understand WHY, on a bipolar powered audio circuit, non-polars are considered "better" or more "ideal" and I'm still in a fog about it. I talked to some others from a theory standpoint and what I got right was "I don't know". The question that came up is whether or not the non-polar caps are essentially two polar caps back-to-back in one can and if that is the case you are essentially doubling that number of caps when you replace polar coupling caps with non-polar. If that's the case then whether or not having more caps in the path is outweighed by the benefit of the non-polar cap's ability to handle being reverse-biased I don't know. What shows up on paper may not be apparent to the ear. I went ahead and cut open a polar and a non-polar cap to see if I could identify anything physically that would shed light on that question about the construction of non-polar caps but no questions were answered. One of my mentors still supposes that it is something "like that", i.e. functionally two polar caps back-to back in one can. Here are some chopped up caps...the polar cap is on the left, the non-polar on the right:

I guess the other Nichicon option is the EP series caps which are 105C rated, but not "audio-grade" which may not matter one little bit...the marketing people would love it if I thought it did I suppose...but they are even more expensive than the 85C rated ES "MUSE" parts, so who knows.

My

understanding is that this is ALL about biasing...audio signal is relatively extremely complex and electrolytic caps display non-linear performance when their charge state passes through or to "0". Non-polar caps handle it better. A solution is to introduce a bias to the caps so that the polarity of the charge is controlled. If this is done right then it really shouldn't

matter if you have a polar cap installed because the bias current will keep the cap from being reverse biased. Again, non-polar caps handle this better because they are

non-polar. They still have non-linear characteristics when crossing "0" though. To take it a step further I understand that in some SSL consoles they used two back-to-back polar caps for coupling and then tied the midpoint to a DC bias. Dunno if that was worthwhile or not. I hope that somebody smarter than me will read this and correct me where I'm wrong on my understanding.

Anyway,

please take any and all of this with a grain of salt...I'm an unschooled hobbyist. We'd really need to have somebody trained and/or experienced in audio circuitry to have some more affirmative info, but I'm sort of spilling this out here to reinforce why I'm sort of the mind to select good quality parts that are affordable and be done with it...shell out some extra cash to try out the "high-end" parts to compare for myself, but barring any major "ah-HAH!" outcomes of that objective testing it seems like a whole lot of attention to something that may be a whole lot of hoo-haw to try and make the circuit more "perfect" and "clean" and "linear". This mixer will be anything BUT clean and linear. For folks like me and equipment like this it seems that going back to the adage I was told wayyyyy back in the beginning, which is to select good quality low ESR 105C parts is good enough for me. Yes, there are exceptions where space and availability of certain parts back when some gear was manufactured as well as COST may mean that there are cheap "upgrades" today that are beneficial, but I've had to learn where that is evident. Not that I know even a simple majority of those cases with lytics in audio circuits at this point, but I know more than I used to, for instance, about sizing coupling caps in the audio path and how to identify evidence of cost controlling with parts used...identifying the compromises made and then make a choice to sidestep that compromise. I think many of us here would be surprised, especially with the Tascam stuff, just how fine and dandy we are to recap with the same value and voltage rating and just "get good quality 105C rated parts".

Live and learn.

) In the end my re-cap plan was a balancing act of "how can I keep this affordable while improving value where possible/prudent/cost-effective. In your case, with many fewer caps to order and probably a more generous budget (I'm perpetually shoestring), you sure have options I didn't but anyway....Nichicon and Panasonic are both very good choices. I wound up with 99% Panasonics as it's what suited my needs. Yes this meant that the bipolars are 85C caps and that's kind of a bummer, but in the end I resolved that it's not that huge a deal, either way, this is probably the last re-cap this console will get and they'll last a good long time. Would I have popped for Nichicon Muse bipolars if I had the budget and the stocks of the values I wanted were available? Very possible, but not how the cookie crumbled. If I'd had more time and a bigger budget, I would have spent more time working up a scheme that was all about performance and weighed each and every cap's purpose in its place in the circuit (especially the BPs as they're mostly in the signal) but...needs must, oh well!

) In the end my re-cap plan was a balancing act of "how can I keep this affordable while improving value where possible/prudent/cost-effective. In your case, with many fewer caps to order and probably a more generous budget (I'm perpetually shoestring), you sure have options I didn't but anyway....Nichicon and Panasonic are both very good choices. I wound up with 99% Panasonics as it's what suited my needs. Yes this meant that the bipolars are 85C caps and that's kind of a bummer, but in the end I resolved that it's not that huge a deal, either way, this is probably the last re-cap this console will get and they'll last a good long time. Would I have popped for Nichicon Muse bipolars if I had the budget and the stocks of the values I wanted were available? Very possible, but not how the cookie crumbled. If I'd had more time and a bigger budget, I would have spent more time working up a scheme that was all about performance and weighed each and every cap's purpose in its place in the circuit (especially the BPs as they're mostly in the signal) but...needs must, oh well!

So sorry to hear that the JH-16 isn't working.

So sorry to hear that the JH-16 isn't working.  I'm assuming you are going to keep it though and get it worked on when you can, yes? Get hooked up with that MCI forum I linked above. The JH-16 is a source of aggravation for those that have had them but you'll find help there.

I'm assuming you are going to keep it though and get it worked on when you can, yes? Get hooked up with that MCI forum I linked above. The JH-16 is a source of aggravation for those that have had them but you'll find help there.