happybirthday

Member

Hello pals, i am once again turning to the forum for knowledge. I really appreciate all the help and knowledge i have gotten so far.

Thank you for your time.

I have been using my 8516 quite heavily in the past two years. It has some issues which have started to get quite out of hand. Im hoping to learn more about electronic repair so i can preform work myself to keep this unit alive.

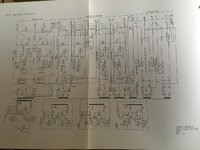

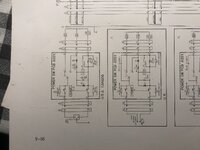

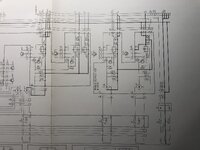

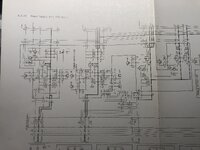

At this point every function still works, however i am getting unacceptable amounts of noise in my amplifier unit on the outputs. I have what i believe is a 120HZ hum in all channels when armed. The heads also appear to be picking this noise up when im playing back the tape and amplifying it when i record. Another noise i am getting is the skreechy sound of the capstan motor, also in all channels. With the amplifier unplugged the cap motor is nice a quiet.

I have a scope and was hoping to trace the hum to the power supply, however i have very little idea of how to do this properly. i can imagine the aged capacitors contributing to this issue, i dont want to blindly replace them, i would like to learn how to trace this noise properly and learn how to use my scope.

any advice is greatly appreciated.

Best,

mike

Thank you for your time.

I have been using my 8516 quite heavily in the past two years. It has some issues which have started to get quite out of hand. Im hoping to learn more about electronic repair so i can preform work myself to keep this unit alive.

At this point every function still works, however i am getting unacceptable amounts of noise in my amplifier unit on the outputs. I have what i believe is a 120HZ hum in all channels when armed. The heads also appear to be picking this noise up when im playing back the tape and amplifying it when i record. Another noise i am getting is the skreechy sound of the capstan motor, also in all channels. With the amplifier unplugged the cap motor is nice a quiet.

I have a scope and was hoping to trace the hum to the power supply, however i have very little idea of how to do this properly. i can imagine the aged capacitors contributing to this issue, i dont want to blindly replace them, i would like to learn how to trace this noise properly and learn how to use my scope.

any advice is greatly appreciated.

Best,

mike