evm1024

New member

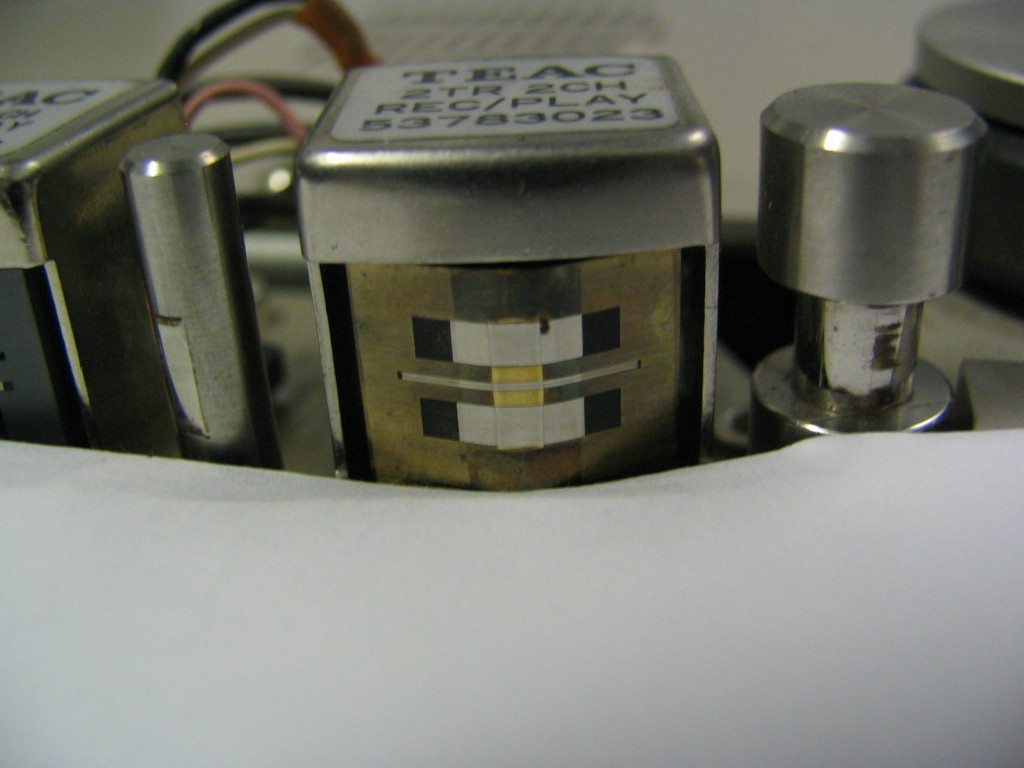

It is time to re-lap a few MCI headstacks. One is Mine and the other belongs to Jortiz. I like to get some practice in before risking an otherwise good head. I have a MCI headstack or two floating around so I have started with the most wornout one. Here is a scan of the Rec and PB heads.

The PBhead is on the right and has not been touched. As you can see the flat spot on the head goes the full width of the relief slots. It appears to be worn flat to nearly the full depth of the relief slots. And, you can see that the gap is blown out. It is so worn that the gap has started opening up. Of course it is dirty and not at all nice looking.

The left head is the Record head. It was not so worn to start with so I chose it to practice on. The gap has not started opening up yet (but given the wear on the PB head this is not too far in the future). As you can see the relief slots are about half the size the originally were. I have not started polishing this head yet. Just lapping to get rid of the flat spot and restore the original headshape. I did this by lapping the sides of the center of the head and leaving the gap area alone. As the lapping progressed the edges of the flat moved closer to the gap. I monitored the edges of the flat spot and adjusted the lapping motion to keep the flat spot edges straight, parallel to the gap and equal distances from the gap. This keeps it all centered. As the flat spot edges got closer and closer to the gap they merged at the gap and I stopped. I really do not want to take any of the gap away given the wear of this head.

I'm out of abrasives right now so this was a good time to stop. Next up in a day or 2 will be increasing fine abrasives up to 1500 grit followed by lapping film to put a nice polish on the head. I'm thinking that this will remove any remaining hint of a flat spot as well.

I'll have to cobble up an LC meter so that I can measure the inductance of the head. I do know the inductance of a new head so this might give me a hint of the remaining head life. I'm guessing that this Rec head has less than 10% (more likely < 5%) left.

In any case this is just practice with Mine and John's heads coming sometime next week or a bit later (Darn, work gets in the way). Certainly, done by the end of Feb.

regards, ethan

The PBhead is on the right and has not been touched. As you can see the flat spot on the head goes the full width of the relief slots. It appears to be worn flat to nearly the full depth of the relief slots. And, you can see that the gap is blown out. It is so worn that the gap has started opening up. Of course it is dirty and not at all nice looking.

The left head is the Record head. It was not so worn to start with so I chose it to practice on. The gap has not started opening up yet (but given the wear on the PB head this is not too far in the future). As you can see the relief slots are about half the size the originally were. I have not started polishing this head yet. Just lapping to get rid of the flat spot and restore the original headshape. I did this by lapping the sides of the center of the head and leaving the gap area alone. As the lapping progressed the edges of the flat moved closer to the gap. I monitored the edges of the flat spot and adjusted the lapping motion to keep the flat spot edges straight, parallel to the gap and equal distances from the gap. This keeps it all centered. As the flat spot edges got closer and closer to the gap they merged at the gap and I stopped. I really do not want to take any of the gap away given the wear of this head.

I'm out of abrasives right now so this was a good time to stop. Next up in a day or 2 will be increasing fine abrasives up to 1500 grit followed by lapping film to put a nice polish on the head. I'm thinking that this will remove any remaining hint of a flat spot as well.

I'll have to cobble up an LC meter so that I can measure the inductance of the head. I do know the inductance of a new head so this might give me a hint of the remaining head life. I'm guessing that this Rec head has less than 10% (more likely < 5%) left.

In any case this is just practice with Mine and John's heads coming sometime next week or a bit later (Darn, work gets in the way). Certainly, done by the end of Feb.

regards, ethan

That playback head almost looks like mine!

That playback head almost looks like mine!