You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fix and keep? Fix and sell? Part it out?

- Thread starter sweetbeats

- Start date

A Reel Person

It's Too Funky in Here!!!

You are incorrigible!

I'd keep it. That's a sweet board & could be used as a sidecar to your M-XXXX Frankenboard.

What seems to be wrong with it? It looks in good condition?

Anyway,... you need another project to fill your empty existence!

PS: how much $ & what's the "catch"?

(... & You should customize it with some "dim" bulbs!)

I'd keep it. That's a sweet board & could be used as a sidecar to your M-XXXX Frankenboard.

What seems to be wrong with it? It looks in good condition?

Anyway,... you need another project to fill your empty existence!

PS: how much $ & what's the "catch"?

(... & You should customize it with some "dim" bulbs!)

technoplayer

Recovering Gear-aholic

Brought home another stray Cory?? For the love of.......

Sell it and concentrate on your studio!

We have to put you on a 12 step program..............

Sell it and concentrate on your studio!

We have to put you on a 12 step program..............

Hammerstone

Out of style

Turn it around, make a profit, take your wife to dinner.

technoplayer

Recovering Gear-aholic

Exactly!!!

sweetbeats

Reel deep thoughts...

Well folks I'm not living at home right now and taking the wife to dinner would be...awkward. And no its not related to gear.

But nonetheless I did pick this M-512 up with the thoughts of parting it out for profit and or if the repairs were simple enough then repairing it and reselling for a profit. I need money for rent and food after all.

So this M-512 came with the manual (which is in EXCELLENT condition but missing a page), and the bill of goods I was sold was that it had some water damage that was making channels 1-4 inoperable, and that a fader knob and 10 color caps were missing.

$100

When I arrived it actually looked like the water damage was around the balance amp out jacks and some of the master section RCA jacks and the bottom of the lower rear cross-member (a little rust), so right away I figured water damage wasn't likely the cause of the channel 1~4 problem. Also I noticed the SLATE level pot shaft was broken off. I also noticed the bottom pan under the master section was deformed so I had concern about damage to master section components but the seller said the master section was working 100%.

There were other usual cosmetic issues like banged up trim panels, scunge, but overall a "will clean up nice" candidate.

Obviously I picked it up anyway.

Here are some general pics:

I ALREADY SWAPPED THE METER BRIDGE END CAPS...HIDES THIS DAMAGE.

First thing I did was check out the bottom of the master section and that tweaked panel. Everything looked alright under there.

Here you can see the pushed in panel:

And before and after shots:

Then I took a closer look at the water damage...the RCA jacks will clean up nice. The XLR jacks are pretty sad BUT I have a sizable collection of those very jacks in excellent condition with good hardware so I'll swap those out...I'm not planning on doing anything with the rusted cross-member:

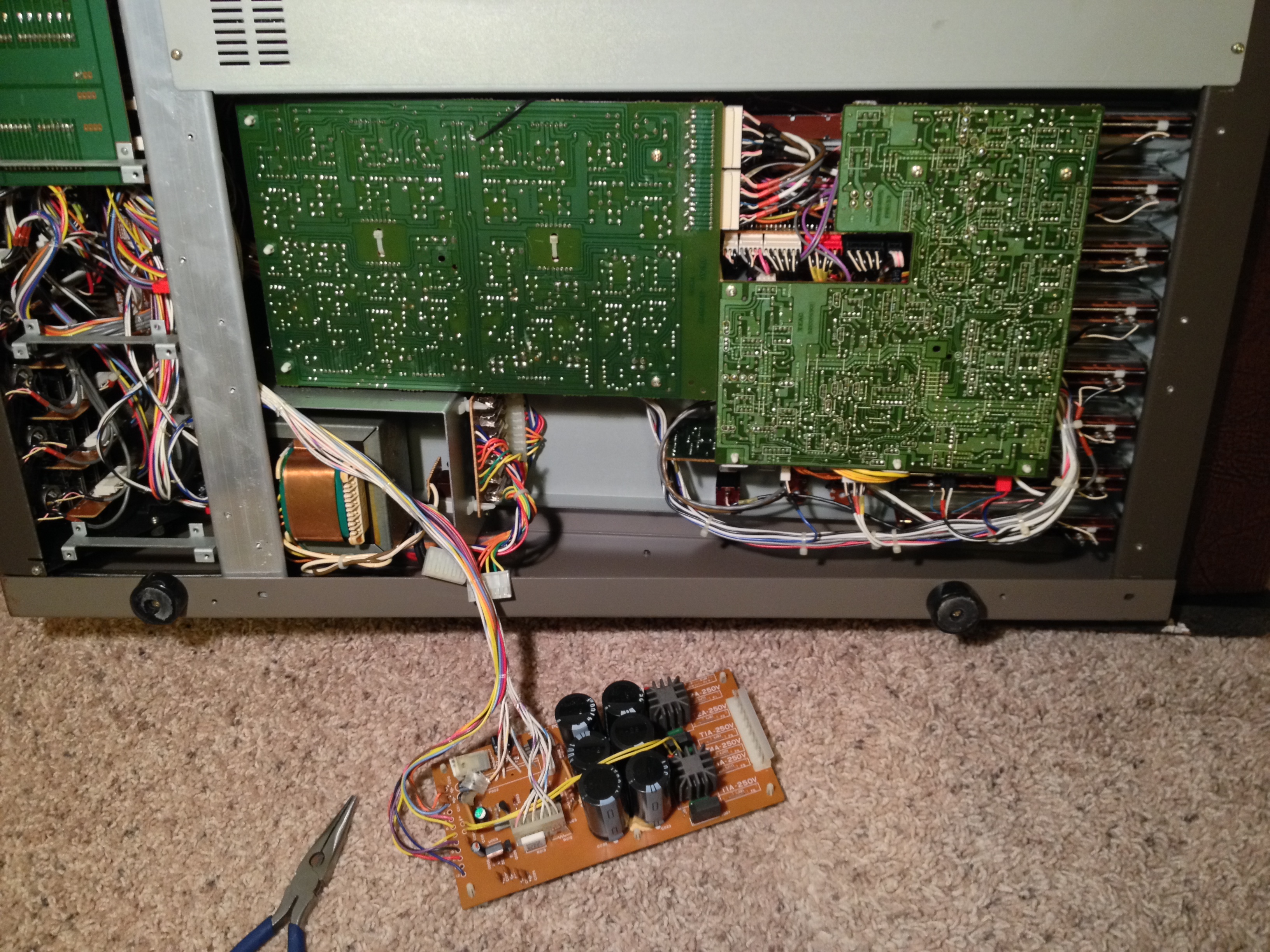

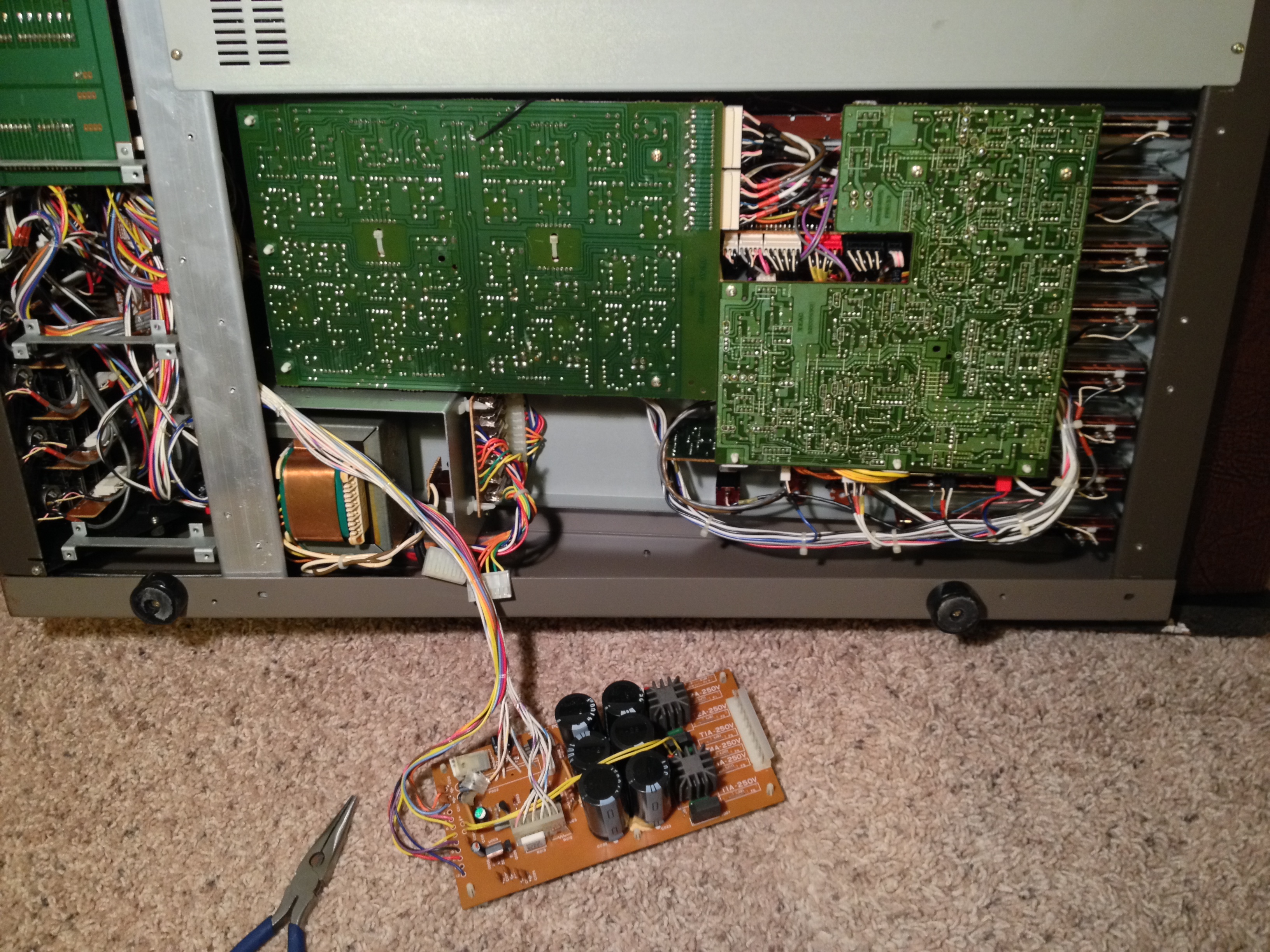

So with water damage my mind immediately goes to "how does it look inside??"

Fortunately it really looks like all the trouble is just to the exterior, and like I said the RCA jacks will clean up nice and the XLRs I will replace. Here is what it looks like from the inside of those XLRs:

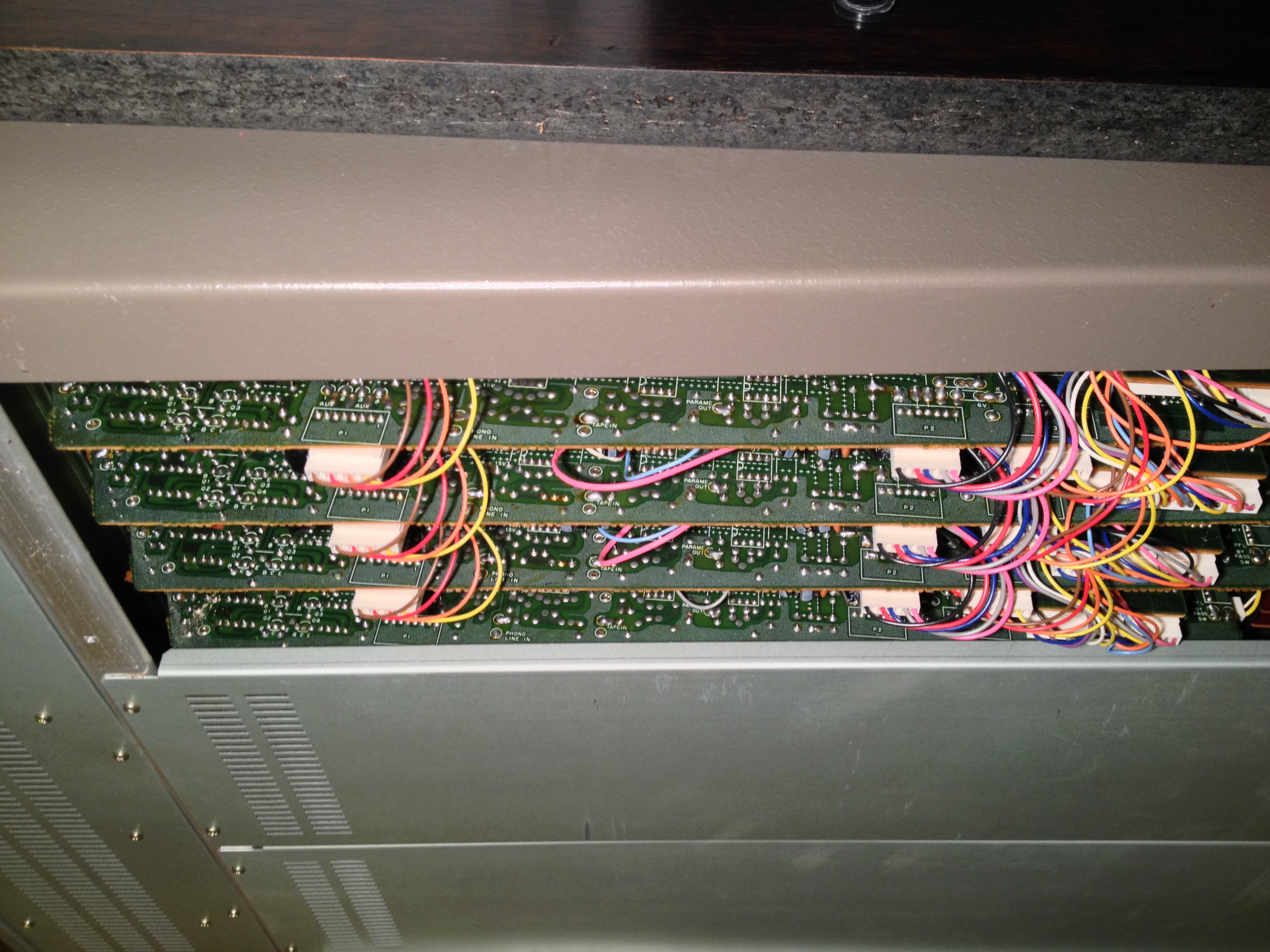

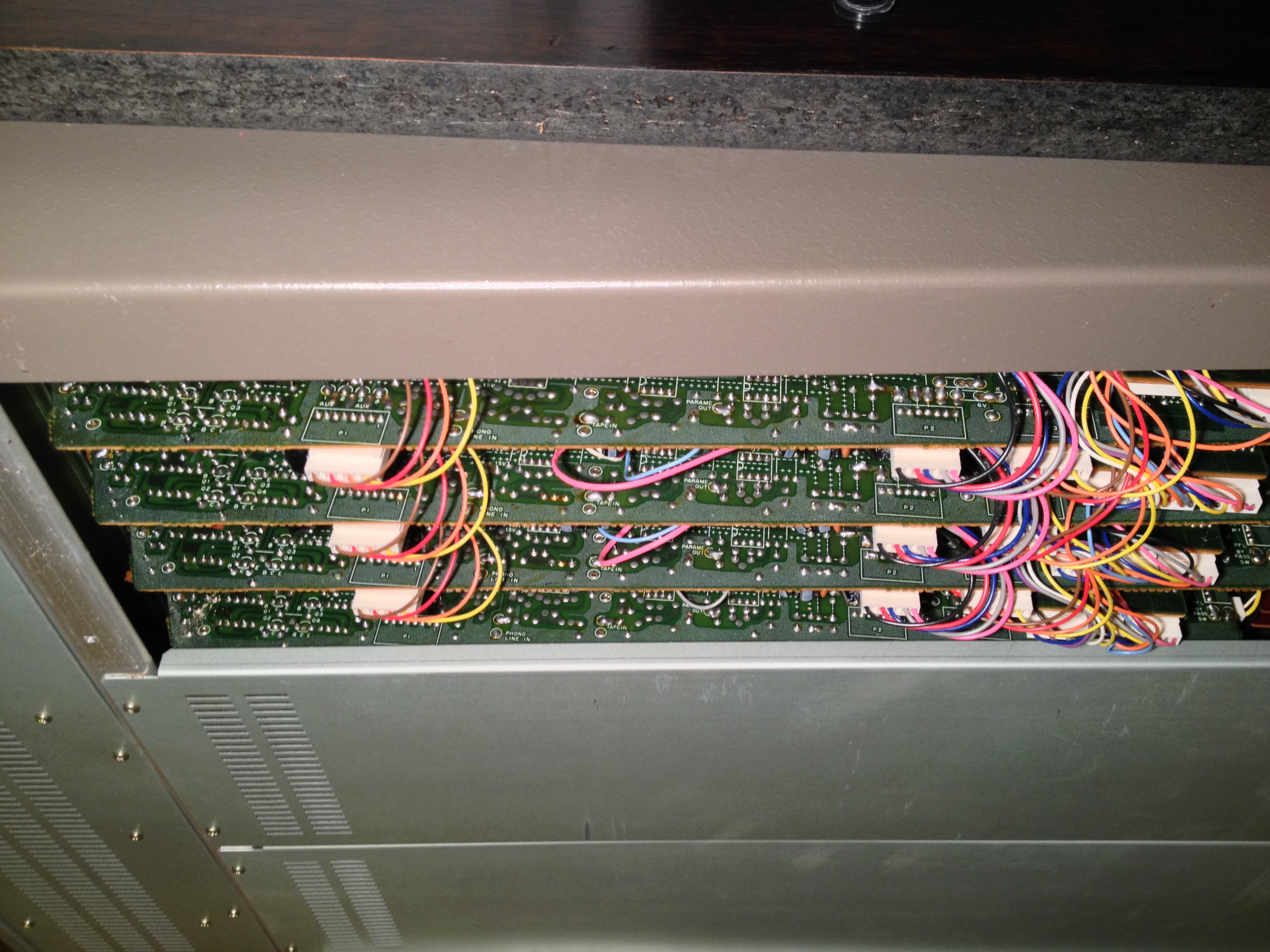

And actually overall this mixer is very clean inside, and it appears was well cared for at least until a point...I think it was kept clean for most of its life. I forgot how much I like the construction design of the M-500 boards. Tascam did a nice job with the engineering of them.

Random pics of guts:

Okay...so channels 1~4. What's the deal you ask? I noticed during my initial tour once I got the thing to my place the dress panel for that module was distorted...push down in the center. Bad...can you see it in these pics?

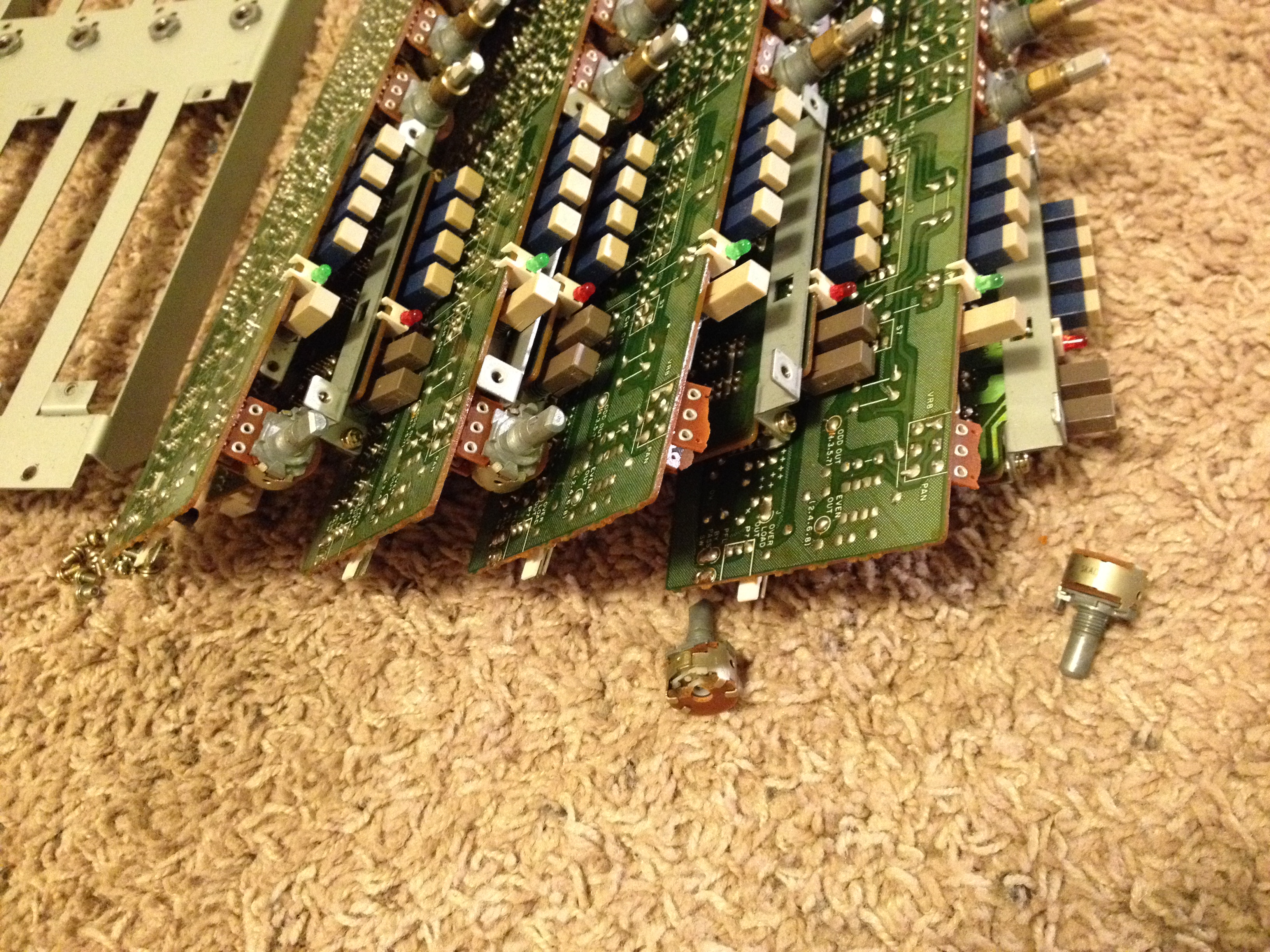

My worst fear was cracked channel PCBs. So I took off the bottom panel for that section and [sigh of relief] they look okay:

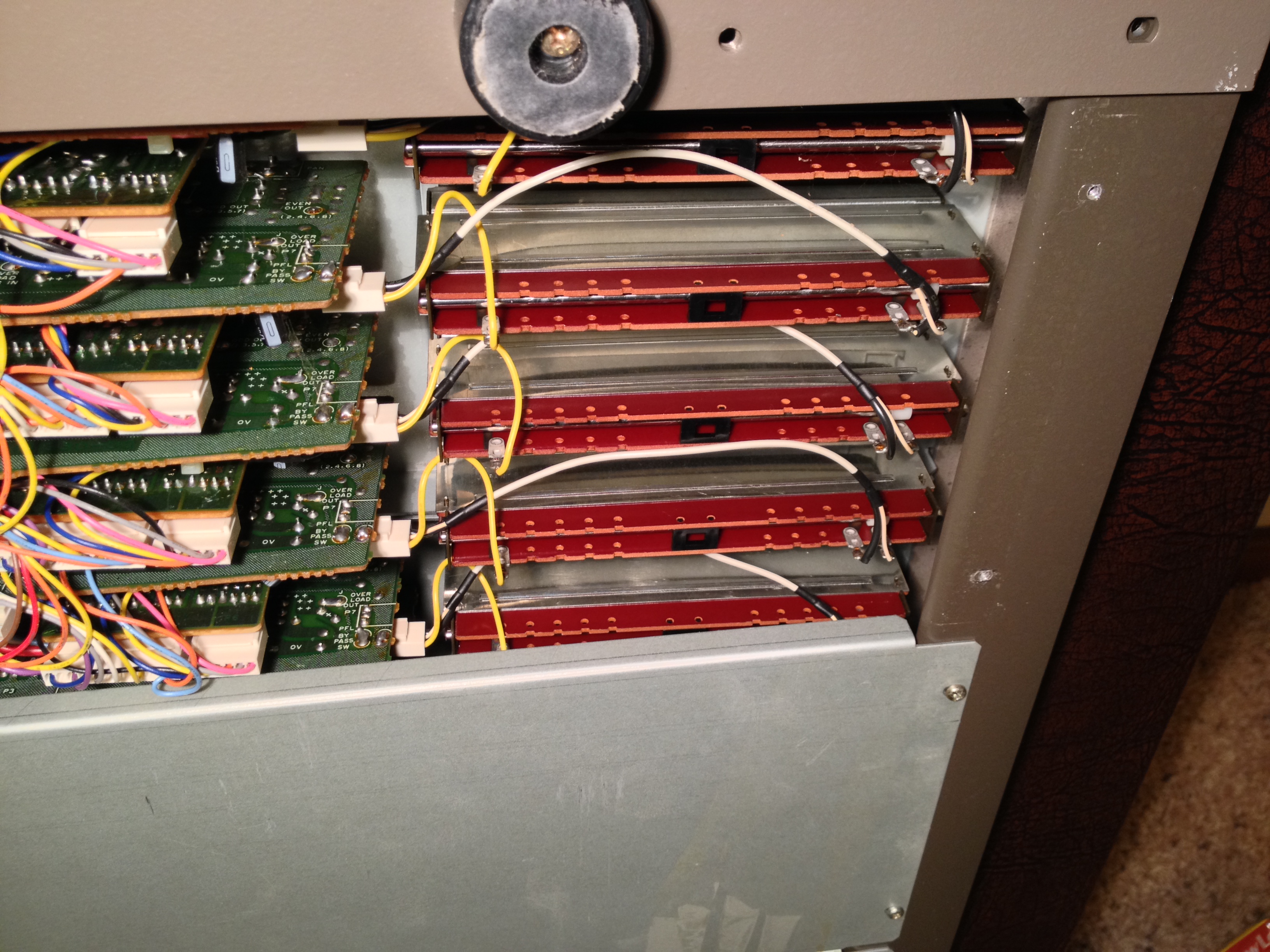

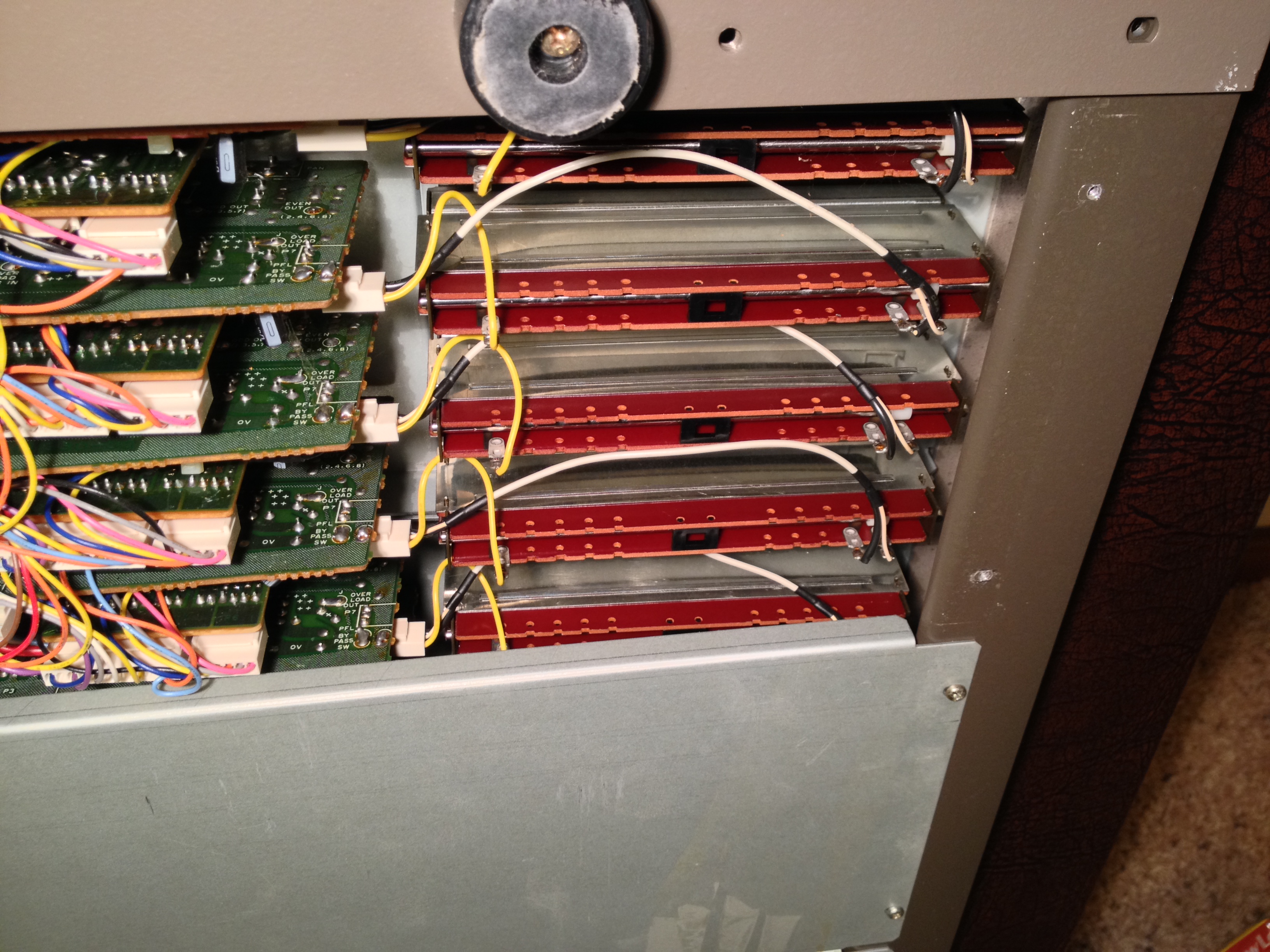

I *also* noticed that this board was fitted with the nicer ALPS faders.

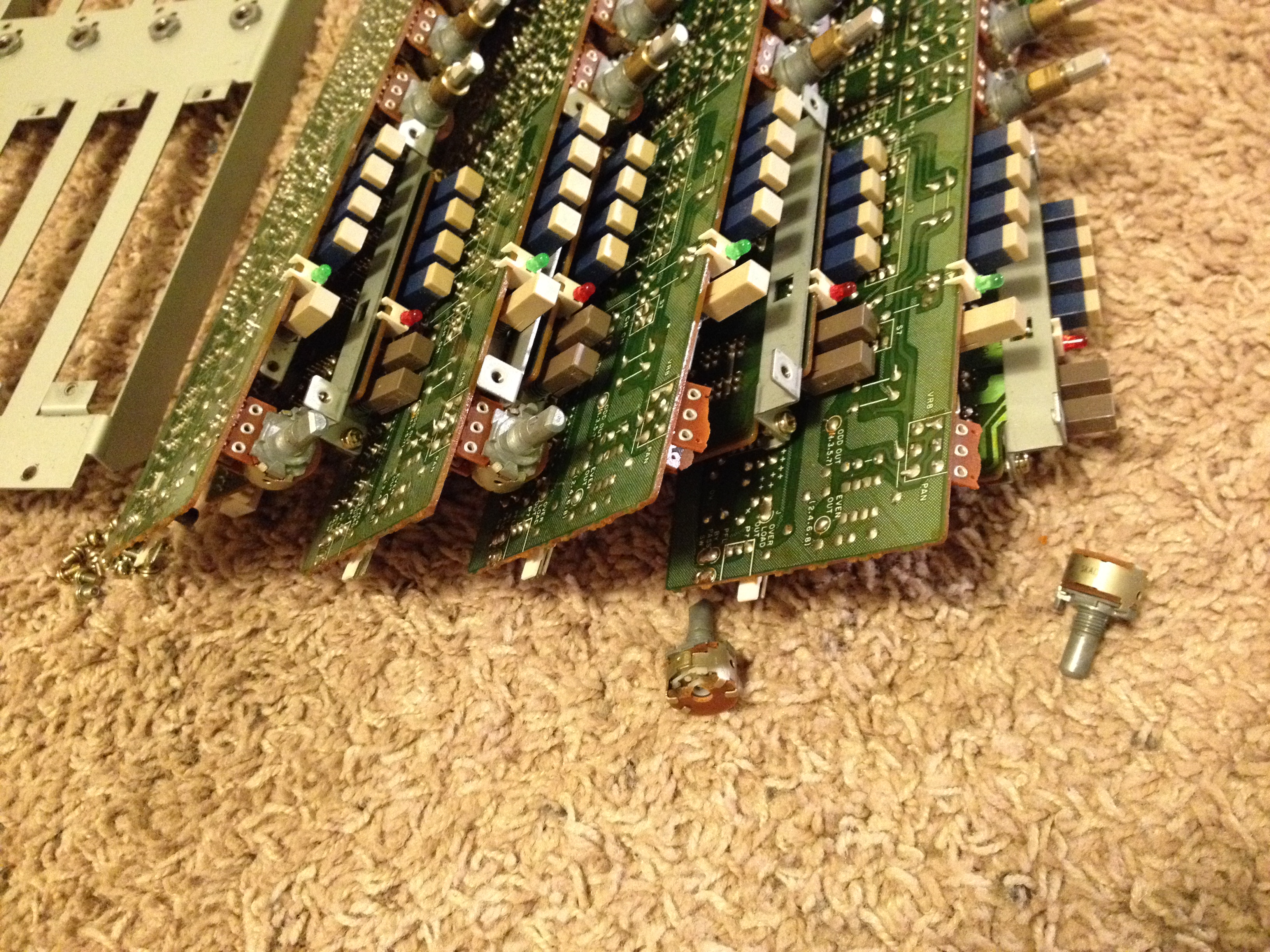

So I stripped the cards off the module and the culprit became readily apparent because the parts fell on the floor...busted pan knobs...everything goes through these and if they're busted, no signal:

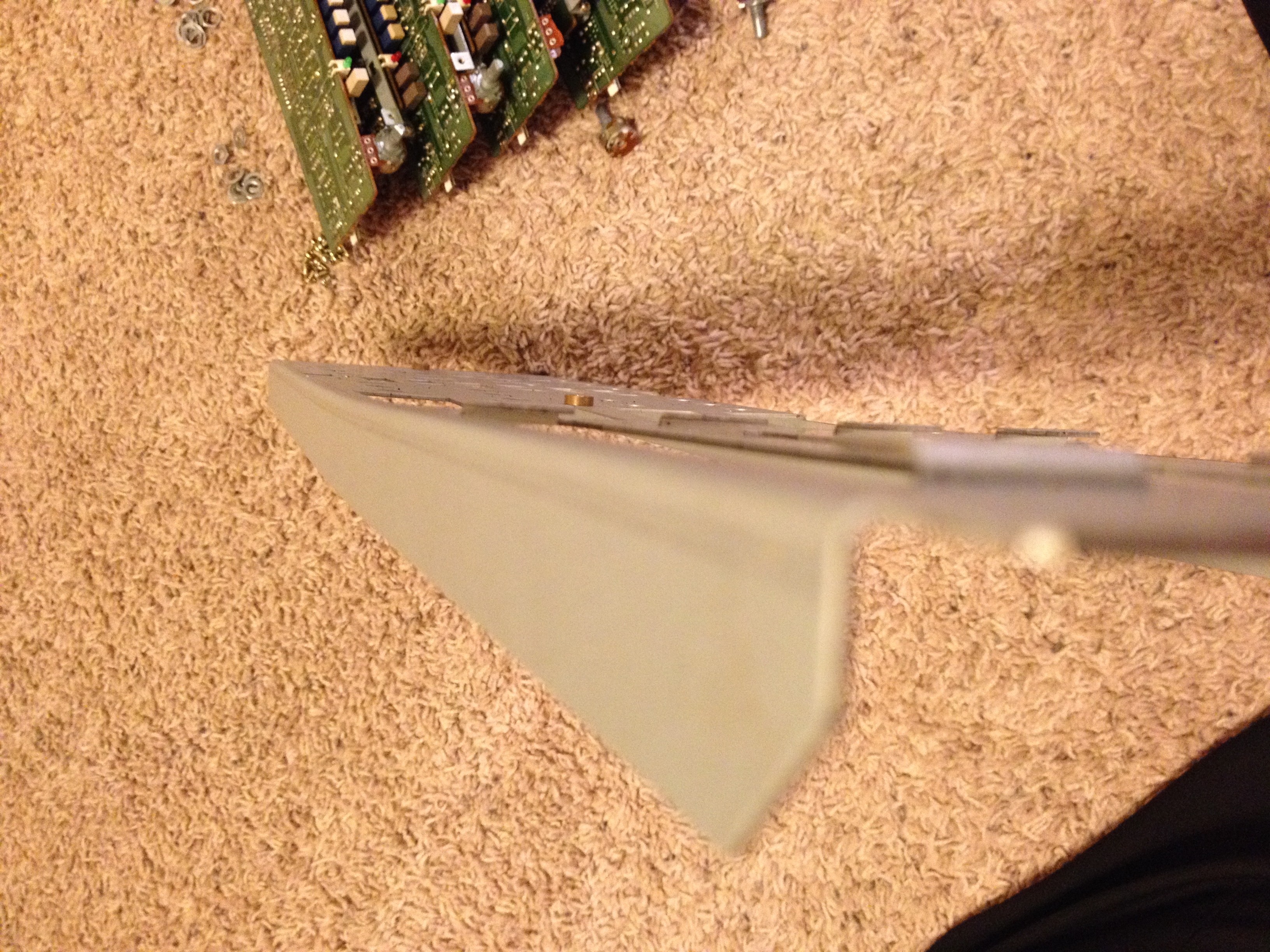

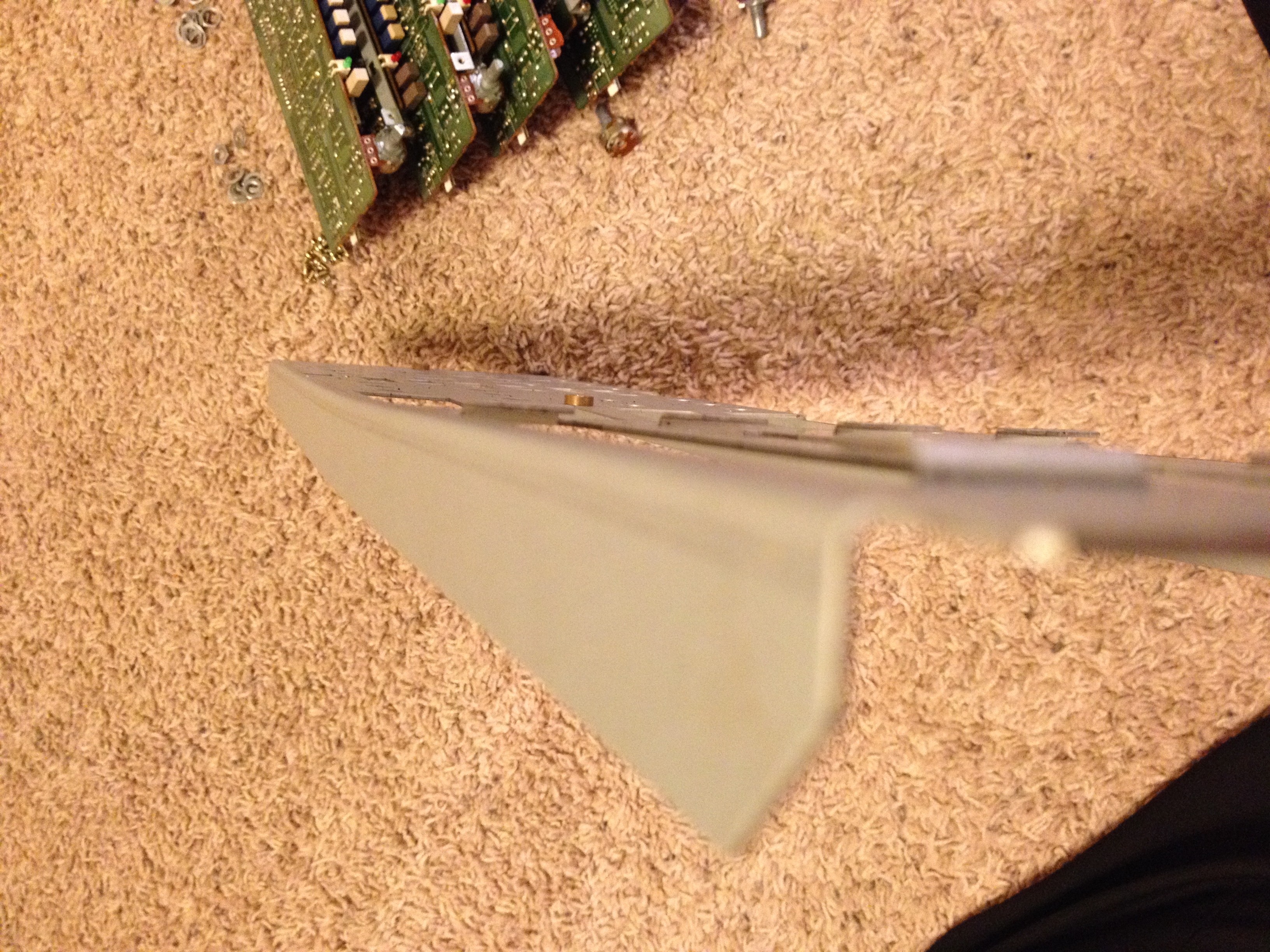

Here is the chassis panel that needs straightened yet:

I'm realistic in accepting that the broken PAN pots may not be the full extend of the damage.

So overall I'm thinking of swapping out those XLR jacks in the balance amp section, replacing the PAN pots for channels 1~4 as well as the SLATE level pot, replacing the missing fader knob and color caps, and I also believe PGM BUSS 1 is non-functional so I'd like to chase that down...clean it up annnnnd...I dunno.

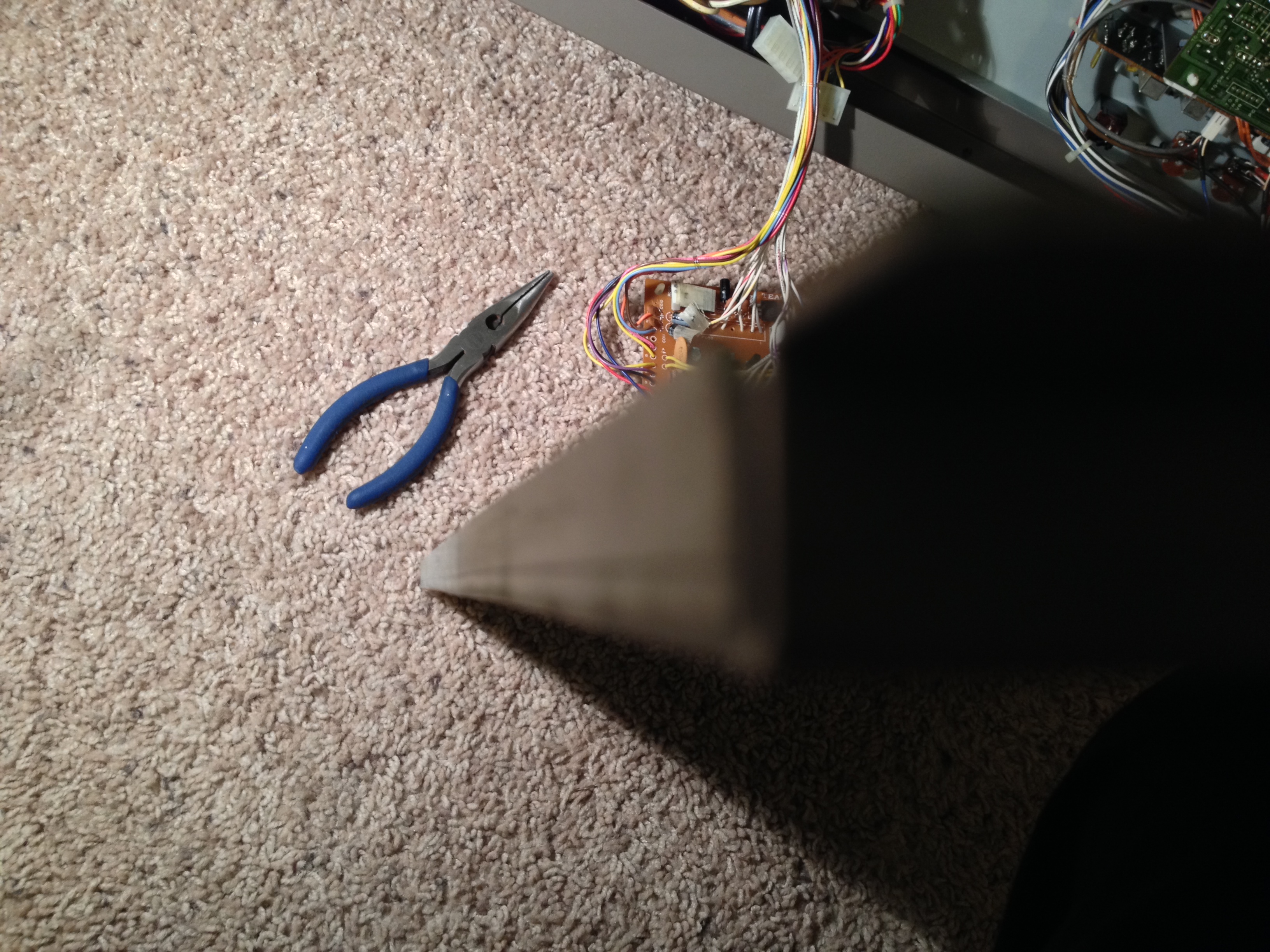

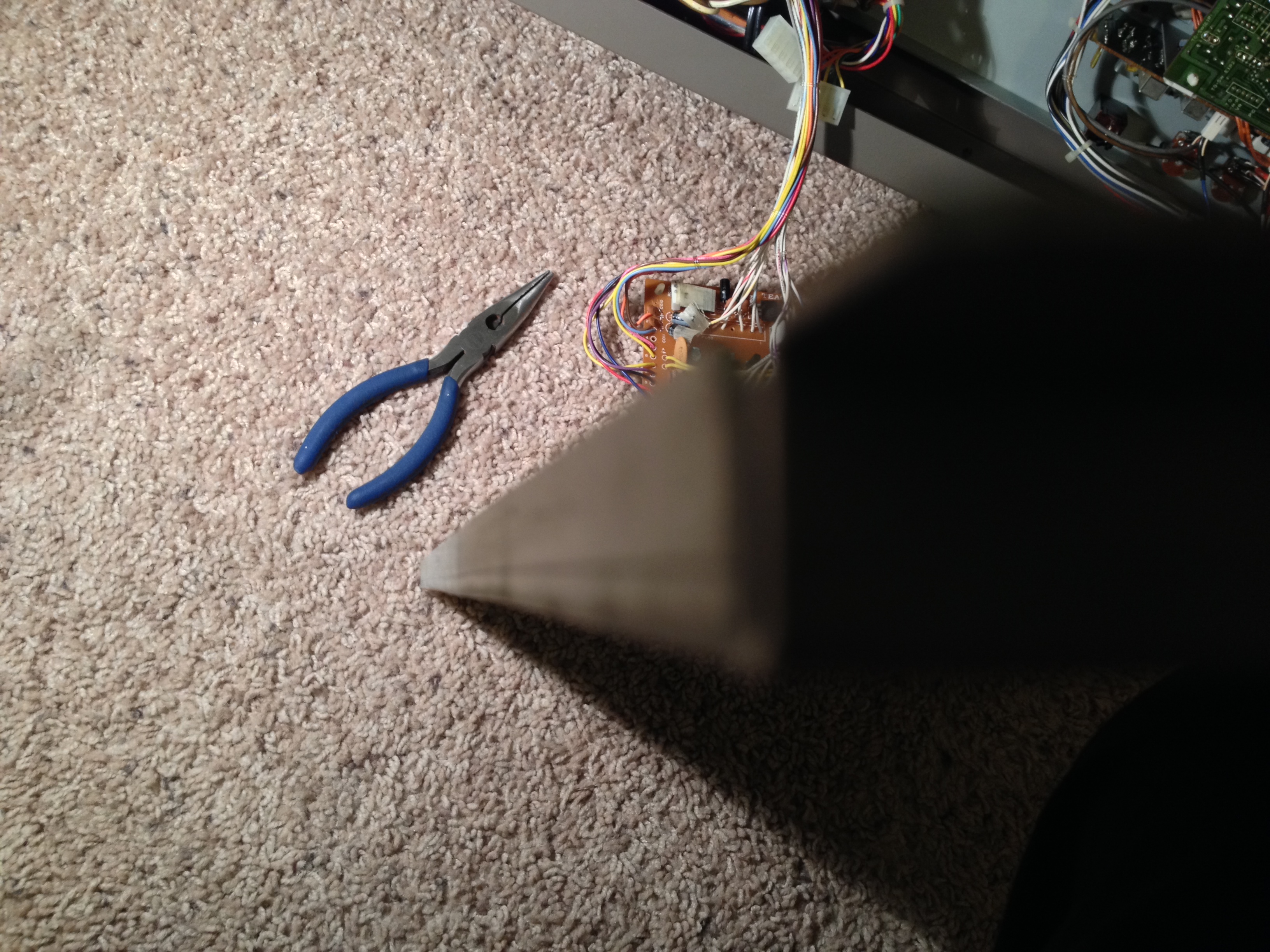

Anyway here's how it looks at one point in the night...ohhhh the carnage:

But nonetheless I did pick this M-512 up with the thoughts of parting it out for profit and or if the repairs were simple enough then repairing it and reselling for a profit. I need money for rent and food after all.

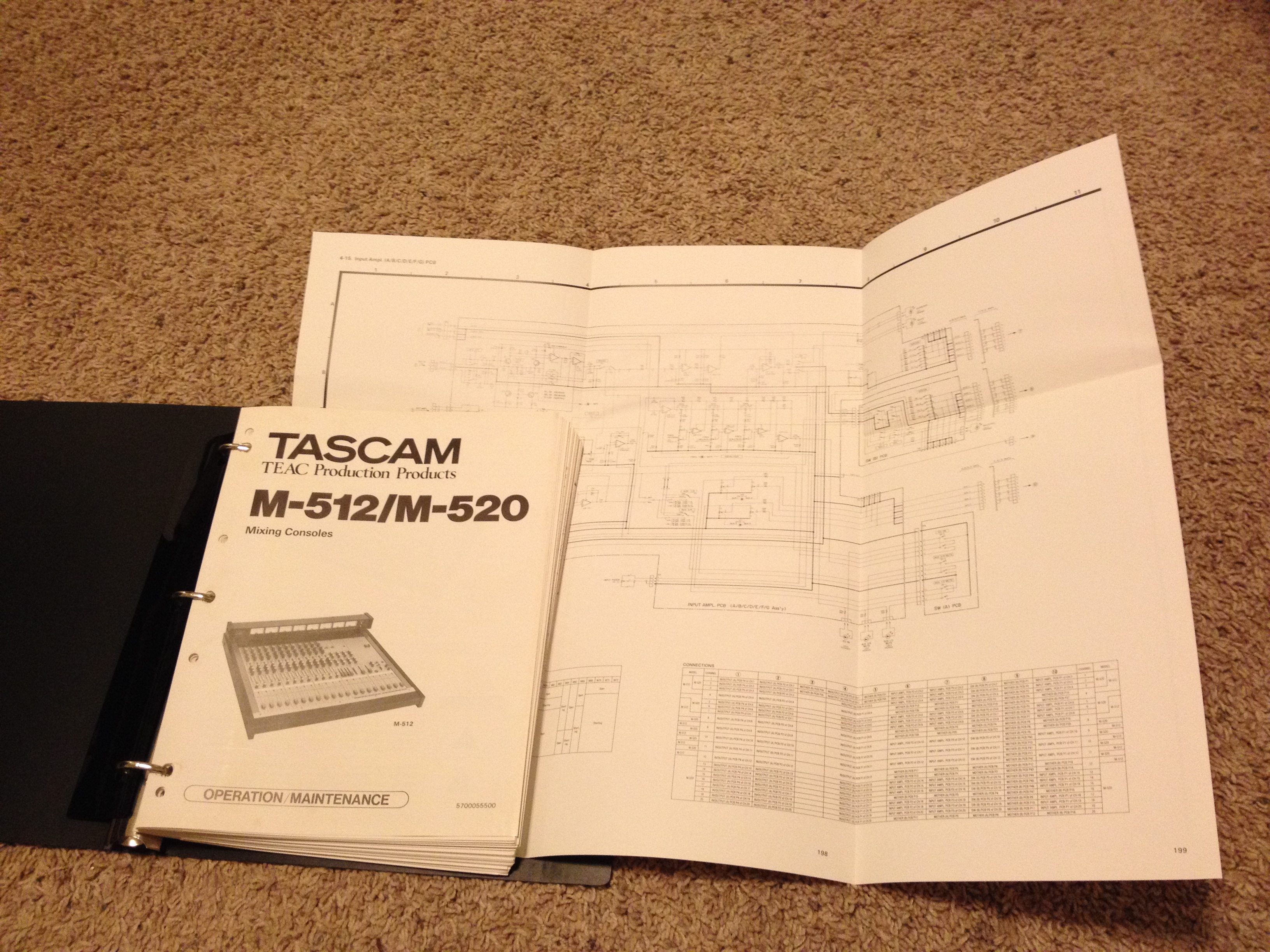

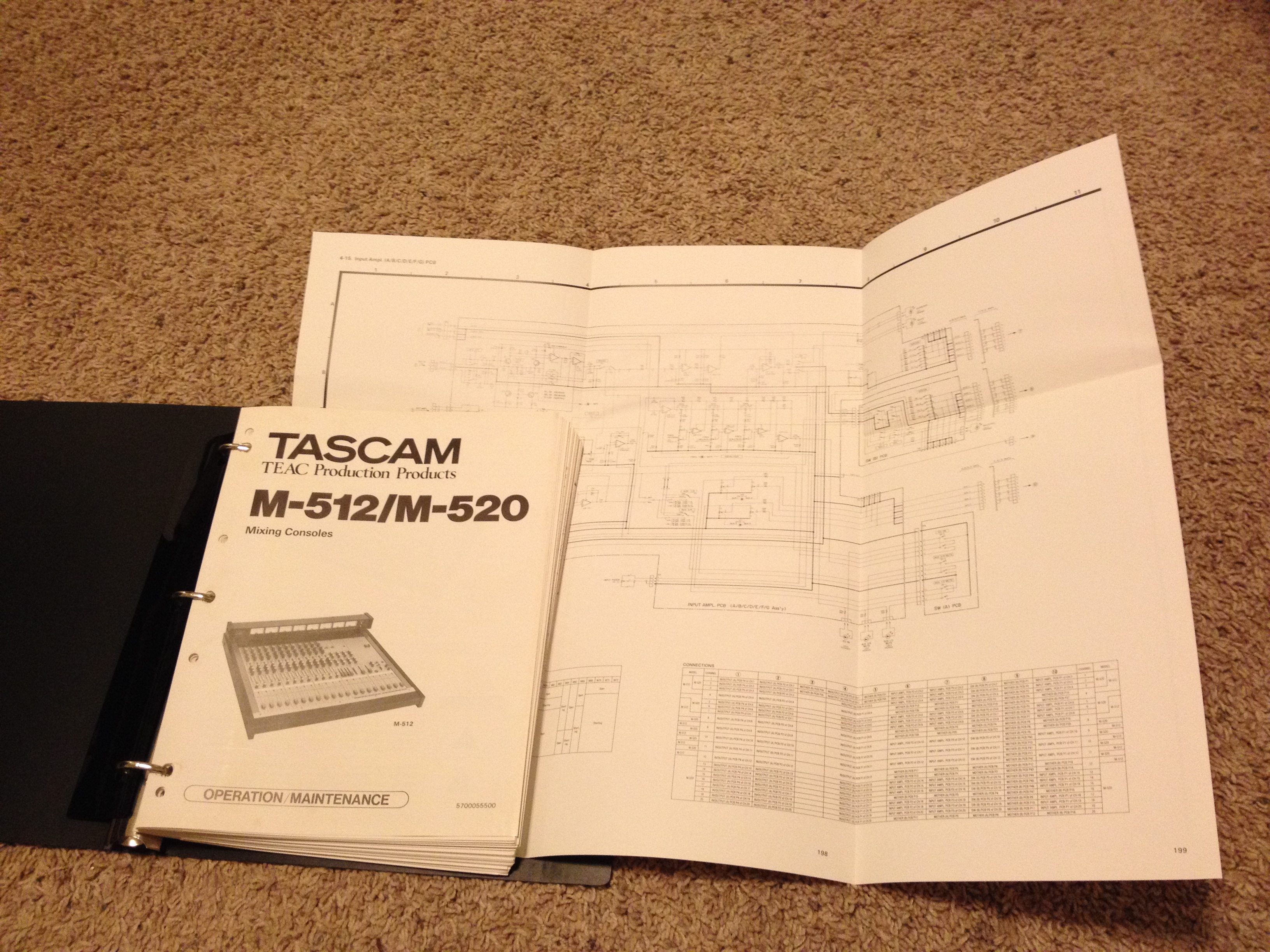

So this M-512 came with the manual (which is in EXCELLENT condition but missing a page), and the bill of goods I was sold was that it had some water damage that was making channels 1-4 inoperable, and that a fader knob and 10 color caps were missing.

$100

When I arrived it actually looked like the water damage was around the balance amp out jacks and some of the master section RCA jacks and the bottom of the lower rear cross-member (a little rust), so right away I figured water damage wasn't likely the cause of the channel 1~4 problem. Also I noticed the SLATE level pot shaft was broken off. I also noticed the bottom pan under the master section was deformed so I had concern about damage to master section components but the seller said the master section was working 100%.

There were other usual cosmetic issues like banged up trim panels, scunge, but overall a "will clean up nice" candidate.

Obviously I picked it up anyway.

Here are some general pics:

I ALREADY SWAPPED THE METER BRIDGE END CAPS...HIDES THIS DAMAGE.

First thing I did was check out the bottom of the master section and that tweaked panel. Everything looked alright under there.

Here you can see the pushed in panel:

And before and after shots:

Then I took a closer look at the water damage...the RCA jacks will clean up nice. The XLR jacks are pretty sad BUT I have a sizable collection of those very jacks in excellent condition with good hardware so I'll swap those out...I'm not planning on doing anything with the rusted cross-member:

So with water damage my mind immediately goes to "how does it look inside??"

Fortunately it really looks like all the trouble is just to the exterior, and like I said the RCA jacks will clean up nice and the XLRs I will replace. Here is what it looks like from the inside of those XLRs:

And actually overall this mixer is very clean inside, and it appears was well cared for at least until a point...I think it was kept clean for most of its life. I forgot how much I like the construction design of the M-500 boards. Tascam did a nice job with the engineering of them.

Random pics of guts:

Okay...so channels 1~4. What's the deal you ask? I noticed during my initial tour once I got the thing to my place the dress panel for that module was distorted...push down in the center. Bad...can you see it in these pics?

My worst fear was cracked channel PCBs. So I took off the bottom panel for that section and [sigh of relief] they look okay:

I *also* noticed that this board was fitted with the nicer ALPS faders.

So I stripped the cards off the module and the culprit became readily apparent because the parts fell on the floor...busted pan knobs...everything goes through these and if they're busted, no signal:

Here is the chassis panel that needs straightened yet:

I'm realistic in accepting that the broken PAN pots may not be the full extend of the damage.

So overall I'm thinking of swapping out those XLR jacks in the balance amp section, replacing the PAN pots for channels 1~4 as well as the SLATE level pot, replacing the missing fader knob and color caps, and I also believe PGM BUSS 1 is non-functional so I'd like to chase that down...clean it up annnnnd...I dunno.

Anyway here's how it looks at one point in the night...ohhhh the carnage:

Last edited:

Hammerstone

Out of style

Sweetbeats, it looks like you scored again, good luck with it!

In the interest of helping you overcome your "problem," I'll take one if they're free...

i am a hoarder so i say keep iti have three tascam 32s that i want to get rid of, anyone?

In the interest of helping you overcome your "problem," I'll take one if they're free...

i always loved the M series but never owned one. They really have all the features of a great inline console. About the Tascam 32s. One of them i restored to like new state and it took me a while, so i developed this emotional attachment tho those machines, but i know i have to let them go, as i have too many half track decks and the 32s are at the lower end, but it is hard to get rid of them...anyone experienced that ? or is it just me?

Hammerstone, i'm not there yet to give them away for free

Hammerstone, i'm not there yet to give them away for free

sweetbeats

Reel deep thoughts...

Found 3 of the 4 pan pots needed for the channel 1~4 repair and got them soldered in...pulled the busted slate level pot...don't have a good 10K pot so I dismantled the broken pot and swapped in a good shaft...

Should be able to pick up the replacement XLR jacks and hardware this weekend and look for another pan pot.

Still undecided as to where to go with this thing. There are parts that are common between my prototype Tascam M-__ console and the 500 series so this M-512 could make a great parts donor for spares and still be able to make a profit or at least come out even by selling some parts...I could trade out all the bottom knobs of the stacked knobs on the M-__ (the M-500 boards have a different knob design which makes it MUCH easier to see/feel the current position of that bottom knob than the ones fitted to the M-__)...could do some more colorization of knob caps on the M-__ too (since originally ALL the knob caps on the M-__ were the putty color...makes navigating difficult at times). But then again I think this M-512 is going to be an easy cleanup/fix up...could flip and be done...or keep...the M-__ is so very very cool but still temperamental and "buggy". Sometimes it's nice to have something that just *works* and doesn't have so many bells and whistles...

Anyway...just some of the stuff going through my head. It's fun being inside an M-500 board again though...it's always fun working on something that is very familiar...makes the partial disassembly and troubleshooting work FAST.

Should be able to pick up the replacement XLR jacks and hardware this weekend and look for another pan pot.

Still undecided as to where to go with this thing. There are parts that are common between my prototype Tascam M-__ console and the 500 series so this M-512 could make a great parts donor for spares and still be able to make a profit or at least come out even by selling some parts...I could trade out all the bottom knobs of the stacked knobs on the M-__ (the M-500 boards have a different knob design which makes it MUCH easier to see/feel the current position of that bottom knob than the ones fitted to the M-__)...could do some more colorization of knob caps on the M-__ too (since originally ALL the knob caps on the M-__ were the putty color...makes navigating difficult at times). But then again I think this M-512 is going to be an easy cleanup/fix up...could flip and be done...or keep...the M-__ is so very very cool but still temperamental and "buggy". Sometimes it's nice to have something that just *works* and doesn't have so many bells and whistles...

Anyway...just some of the stuff going through my head. It's fun being inside an M-500 board again though...it's always fun working on something that is very familiar...makes the partial disassembly and troubleshooting work FAST.

miroslav

Cosmic Cowboy

Brought home another stray Cory?? For the love of.......

Sell it and concentrate on your studio!

We have to put you on a 12 step program..............

I figure at some point, there is going to be a yard sale at his house unlike any ever seen before!!!

Too bad he's 3000 miles away.

sweetbeats

Reel deep thoughts...

Got all the metalwork straightened out...

Found that 4th PAN pot and got that soldered in...

Found a replacement pot for the SLATE level pot and got that soldered up and the master section put back together...

All the knob and switch caps are pulled and the dress panels are all removed for cleaning...

Went over everything remaining with toothbrush/paint brush and strong vacuum...

Started looking into the dead PGM BUSS 1 issue...the buss ain't dead...looks like there is a signal wiring problem up to the PGM BUSS 1 meter...I already ruled out a dead meter (switched meter pairs)...this should be easy to rectify...

Tracked down replacement XLR jacks and screws to replace the corroded ones...

Moving right along...

Found that 4th PAN pot and got that soldered in...

Found a replacement pot for the SLATE level pot and got that soldered up and the master section put back together...

All the knob and switch caps are pulled and the dress panels are all removed for cleaning...

Went over everything remaining with toothbrush/paint brush and strong vacuum...

Started looking into the dead PGM BUSS 1 issue...the buss ain't dead...looks like there is a signal wiring problem up to the PGM BUSS 1 meter...I already ruled out a dead meter (switched meter pairs)...this should be easy to rectify...

Tracked down replacement XLR jacks and screws to replace the corroded ones...

Moving right along...

sweetbeats

Reel deep thoughts...

Just following up with some pics.

So thanks to some old M-520 spares I dug up, I found the last couple replacement pots I was looking for...happy to find these spares:

Channel 1~4 PCBs ready to go with replacement PAN pots:

And here's that replacement SLATE level pot ready to nut back in:

Frame and modules stripped for cleaning...obviously the channel 1~4 module isn't back in yet...

And we end the night here...found the PGM BUSS 1 meter issue...sloppy solder job on a staple link up in the meter bridge...so all meters now function as intended. Plus I reassembled and reinstalled the channel 1~4 module and guess what? Though I haven't done a comprehensive test, channels 1~4 now pass tone to all 8 PGM busses and all 4 AUX channels...all mute and solo functions are working. Success! Here we have a pic of all 8 meters at 0VU representing a 1kHz tone input to channel 2 TAPE IN and routed to all 8 groups.

So thanks to some old M-520 spares I dug up, I found the last couple replacement pots I was looking for...happy to find these spares:

Channel 1~4 PCBs ready to go with replacement PAN pots:

And here's that replacement SLATE level pot ready to nut back in:

Frame and modules stripped for cleaning...obviously the channel 1~4 module isn't back in yet...

And we end the night here...found the PGM BUSS 1 meter issue...sloppy solder job on a staple link up in the meter bridge...so all meters now function as intended. Plus I reassembled and reinstalled the channel 1~4 module and guess what? Though I haven't done a comprehensive test, channels 1~4 now pass tone to all 8 PGM busses and all 4 AUX channels...all mute and solo functions are working. Success! Here we have a pic of all 8 meters at 0VU representing a 1kHz tone input to channel 2 TAPE IN and routed to all 8 groups.

A Reel Person

It's Too Funky in Here!!!

Great job so far!

What model Fluke meter is that, & is it sufficient for frequency ranges used in calibration?

I have a Fluke 77 Series II, so is why I ask. Looks identical to the one in the picture.

What model Fluke meter is that, & is it sufficient for frequency ranges used in calibration?

I have a Fluke 77 Series II, so is why I ask. Looks identical to the one in the picture.

sweetbeats

Reel deep thoughts...

What model Fluke meter is that, & is it sufficient for frequency ranges used in calibration?

I have a Fluke 77 Series II, so is why I ask. Looks identical to the one in the picture.

Mine is a Fluke 85, and yes it is a true RMS meter spec'ed for measurements across the audio spectrum:

accurate within 1% 45Hz ~ 1kHz

accurate within 2% 1kHz ~ 5kHz

accurate within 4% 5kHz ~ 20kHz

The above specs are when the meter is auto-ranged to mV which is typically the case when measuring audio stuff at least the -10dBV nominal stuff.

Its been a good meter. I got it used for, like, $50 I think and that came with the yellow rubber case and two sets of probes (one regular and one clip-type). The screen was going wonky so I got a replacement kit for $20 shipped. Has worked like a charm. Fluke stuff lasts.

sweetbeats

Reel deep thoughts...

A Reel Person

It's Too Funky in Here!!!

What's not to like?

sweetbeats

Reel deep thoughts...

Sell it. Youve done your usual high level repair and go through, so you can send it on down the line, proud in knowing that you have returned a hurting piece to excellent condition. Use the money and start over. I think from reading your posts that this process is a catharsis for what ever is currently going on in your life.

sweetbeats

Reel deep thoughts...

Sell it. Youve done your usual high level repair and go through, so you can send it on down the line, proud in knowing that you have returned a hurting piece to excellent condition. Use the money and start over. I think from reading your posts that this process is a catharsis for what ever is currently going on in your life.

Hm. Wow. Thanks for that. Really. I appreciate your willingness to be so bluntly honest.

Yeah...I may indeed sell it. Might not. Not sure yet. My original intention was cheap spare parts for the M-__...I was thinking "Hm...$100, sell the manual and get maybe half my money back...$50 for a ton of spares...good deal...sell some of the spares I don't need, maybe make a profit and have a bunch of spares...done." And when I got it here I couldn't help dig in to see just how easy it would be to bring it back to some state of satisfactory function and condition. Yes...it was cathartic/soothing. Always has been...its just a new season now. But the reality is I have LOTS of opportunities for catharsis already in my midst, so I don't see selling it and getting another project. I think I'm divided about keeping and selling something else. In working with the M-512 its just nice because it doesn't have so many bells and whistles and is easier to use than the M-__...but it still has a comprehensive feature set and a number of neat features the M-__ DOESN'T have that are useful. And its just a nice size. And it has schematics.

It was SO easy to track down the root-cause issues behind the problems this one was having because I have the tech docs. No docs for the M-__. And I forgot how much I like the instrument preamps on the M-500 boards. They make my bass sound amazing. They're nothing special but I think it is just the match of my bass and the preamp...

It was SO easy to track down the root-cause issues behind the problems this one was having because I have the tech docs. No docs for the M-__. And I forgot how much I like the instrument preamps on the M-500 boards. They make my bass sound amazing. They're nothing special but I think it is just the match of my bass and the preamp...Anyway, this M-512 is "done". All back together and 100% tested and functional (except I am unable to test the phono preamps). Since this example is 100% original, it has issues normal to this vintage of mixer...scratchy pots and switches, and a noticeable noise floor, but the scratchy controls aren't bad and can be abated with exercising the particular control. The eq section sometimes squeals depending on the source...I remember that from my M-520 and I also remember it was taken care of by recapping the channel. So I'm not sweating this "normal" behavior. Its not bad. And the noise floor isn't anything out of the ordinary, and I betcha a recap of the power supply along with some selective small-value cap bypassing would bring the same result as with my M-520 which was a significant drop in the noise floor. But I'm not doing any of that at this point if ever with this mixer. Channel 9 SOLO and PFL controls weren't functional but I tipped it up and found a janky connection and took care of that...other than that its 100%. I'd plug it up in my studio as-is.

I think what I need to do is get the M-__ moved over here and play with the two of them side-by-side to help me figure out which direction I want to go.

Anyway, here it is: