Hi everybody,

I finally finished installing all the acoustic panels I built in my music room.

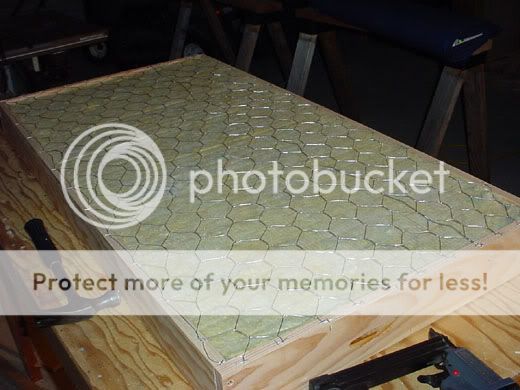

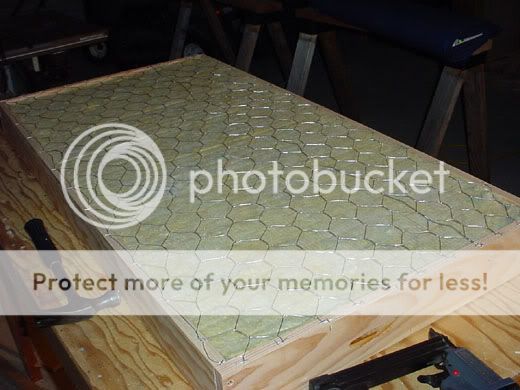

I built ten 2' by 4' 4" thick bass traps covered in blue canvas. They are made from pine 1" by 6" board cut to size and filled with either 8 pound per cubic foot density mineral wool or approximately 3 to 4 pound per cubic foot density fiberglass.

I also built ten 2' by 4' 2" thick panels covered in tan poplin. The frames were made with the same pine board and they were filled with the lighter 3 to 4 pound density fiberglass.

The bass traps are all installed in room corners, either wall/wall corners or wall/ceiling corners, spanning the corner to provide better performance due to the extra air space and positioning.

The tan two inch panels are installed in the three first reflection points on the side walls and ceiling, in the back of the room and on the side walls in other spots to control flutter echoes. They are all spaced out from the wall two inches to make them effective to lower frequencies.

I took the best pictures I could, but I don't have a wide angle lense and the room is only 8' by 11' so there's only so much room to get a good shot. Hopefully you'll be able to get oriented with what you're looking at. The front wall is obvious, but the back wall is the other wall with three bass traps and three tan panels one their sides stacked on top of one another. The wall with the window is to the right of the listening position. The pics more or less take you around the room clockwise.

The monitors are set up to form an equilateral triangle with my head, and sit on two inch thick isolation pads I made from 8 pound density mineral wool covered in the blue canvas. My recorder was transferring some vibration (hum) to the table when the drive spun up so I made one for it as well. You should be able to see them in the pics. The listening position is offset to the left side by just over four inches, and the ceiling first reflection panel is offset to match to avoid a skewed bass response at the listening position due to destructive interference. My head is located about a third of the way into the room from the front wall.

I would really appreciate knowing what you all think of it, I'm very pleased with how it all turned out. It looks much more professional and clean than I expected, and the color scheme worked out well. Kind of reminds me of a nice car interior.

I finally finished installing all the acoustic panels I built in my music room.

I built ten 2' by 4' 4" thick bass traps covered in blue canvas. They are made from pine 1" by 6" board cut to size and filled with either 8 pound per cubic foot density mineral wool or approximately 3 to 4 pound per cubic foot density fiberglass.

I also built ten 2' by 4' 2" thick panels covered in tan poplin. The frames were made with the same pine board and they were filled with the lighter 3 to 4 pound density fiberglass.

The bass traps are all installed in room corners, either wall/wall corners or wall/ceiling corners, spanning the corner to provide better performance due to the extra air space and positioning.

The tan two inch panels are installed in the three first reflection points on the side walls and ceiling, in the back of the room and on the side walls in other spots to control flutter echoes. They are all spaced out from the wall two inches to make them effective to lower frequencies.

I took the best pictures I could, but I don't have a wide angle lense and the room is only 8' by 11' so there's only so much room to get a good shot. Hopefully you'll be able to get oriented with what you're looking at. The front wall is obvious, but the back wall is the other wall with three bass traps and three tan panels one their sides stacked on top of one another. The wall with the window is to the right of the listening position. The pics more or less take you around the room clockwise.

The monitors are set up to form an equilateral triangle with my head, and sit on two inch thick isolation pads I made from 8 pound density mineral wool covered in the blue canvas. My recorder was transferring some vibration (hum) to the table when the drive spun up so I made one for it as well. You should be able to see them in the pics. The listening position is offset to the left side by just over four inches, and the ceiling first reflection panel is offset to match to avoid a skewed bass response at the listening position due to destructive interference. My head is located about a third of the way into the room from the front wall.

I would really appreciate knowing what you all think of it, I'm very pleased with how it all turned out. It looks much more professional and clean than I expected, and the color scheme worked out well. Kind of reminds me of a nice car interior.

If so, I had to be a bearer of bad news. But CANVAS is waterproof ......which translates into NO TRANSPARANCY!!

If so, I had to be a bearer of bad news. But CANVAS is waterproof ......which translates into NO TRANSPARANCY!!  The weave is SEALED. That means, for broadband absorption, air molecules movement can NOT move through the absorbant material, which is required for it to work. Resistive absorbers do their job by FRICTION of air molecules within the "interstices" or fibers, to transduce the energy into heat. If the fabric is not open weave, then it is a reflective surface. Although, it will allow some low frequencys to enter simply because it is similar to a panel absorber. But then the absorbant material is acting like a dampener. At least thats my understanding. I'm sure it works to some extent, but if it is REAL canvas, you won't get the full benefit of the absorber.

The weave is SEALED. That means, for broadband absorption, air molecules movement can NOT move through the absorbant material, which is required for it to work. Resistive absorbers do their job by FRICTION of air molecules within the "interstices" or fibers, to transduce the energy into heat. If the fabric is not open weave, then it is a reflective surface. Although, it will allow some low frequencys to enter simply because it is similar to a panel absorber. But then the absorbant material is acting like a dampener. At least thats my understanding. I'm sure it works to some extent, but if it is REAL canvas, you won't get the full benefit of the absorber.