Somnium7

Noise Criminal

Why bother? Have you seen the price of gas? Have you noticed the price of groceries? Can you say R-E-C-E-S-S-I-O-N?

I like patchcords, I use them pretty much everyday. But they always seem to give up the ghost when I need them most. Hey! Ima poet and don't even know it...

Patchcords cost alot of freakin' moolah in large quantities. Lemme show you how to get patch cords of any length and superior quality for about $5 each.

You'll need to buy a large roll of cable. Then a large number of connectors. How much depends on how many cables you need. Thus I won't get into the where's and whatfors of obtaining these things.

You'll also need heatshrink tubing, solder and tools. Here are the basic tools you will require:

Scissors are helpful too. Notice that the thing with the red handles is 2 tools in one - snipper and stripper.

The big shears (yellow handles) are for cutting the cable. The little hobby knife is for removing the cable's jacket. Big needle nose to crimp the strain relief. Soldering iron for - you guessed it - soldering.

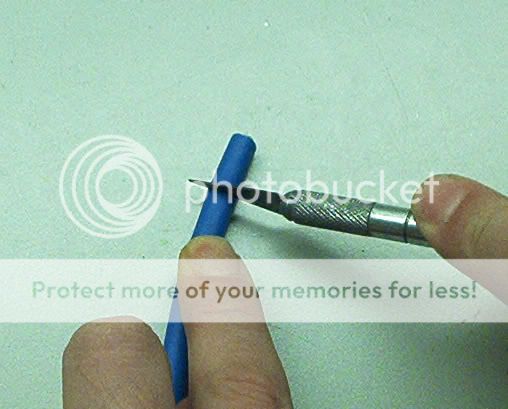

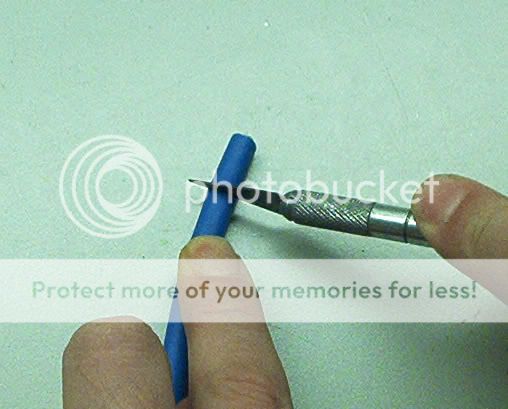

Begin by cutting 1/2 inch of jacket from the cable. Just apply knife and roll across your work surface. When you feel metal through the knife handle you are done.

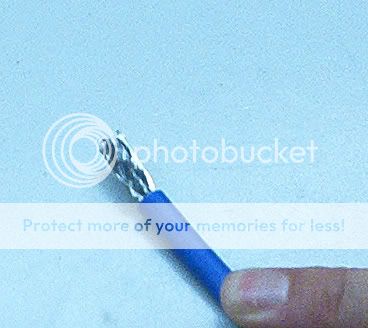

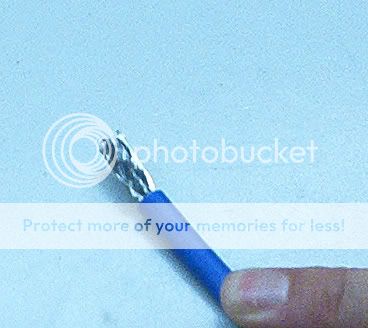

After removing the jacket it should look like this:

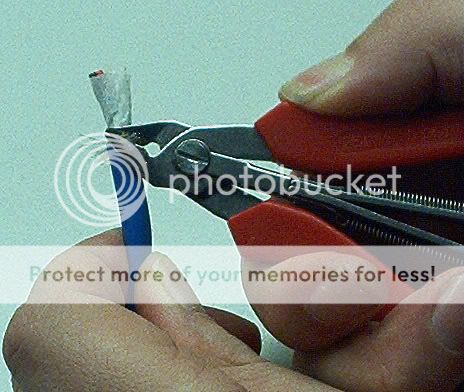

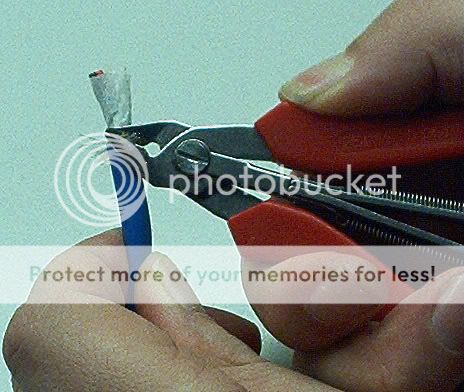

Now you want to trim away half the braided shield wire with your snips:

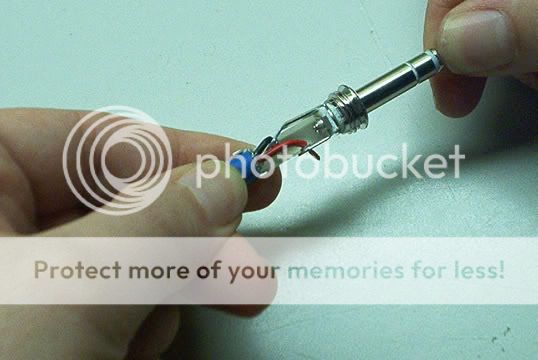

VERY IMPORTANT! Trim a 2 inch length of heatshrink tubing and then slide your connector shell, insulator sleeve and heatshrink onto the cable. Remember to do this for both ends of the cable now or you will be sorry later

Continued in next post.....

I like patchcords, I use them pretty much everyday. But they always seem to give up the ghost when I need them most. Hey! Ima poet and don't even know it...

Patchcords cost alot of freakin' moolah in large quantities. Lemme show you how to get patch cords of any length and superior quality for about $5 each.

You'll need to buy a large roll of cable. Then a large number of connectors. How much depends on how many cables you need. Thus I won't get into the where's and whatfors of obtaining these things.

You'll also need heatshrink tubing, solder and tools. Here are the basic tools you will require:

Scissors are helpful too. Notice that the thing with the red handles is 2 tools in one - snipper and stripper.

The big shears (yellow handles) are for cutting the cable. The little hobby knife is for removing the cable's jacket. Big needle nose to crimp the strain relief. Soldering iron for - you guessed it - soldering.

Begin by cutting 1/2 inch of jacket from the cable. Just apply knife and roll across your work surface. When you feel metal through the knife handle you are done.

After removing the jacket it should look like this:

Now you want to trim away half the braided shield wire with your snips:

VERY IMPORTANT! Trim a 2 inch length of heatshrink tubing and then slide your connector shell, insulator sleeve and heatshrink onto the cable. Remember to do this for both ends of the cable now or you will be sorry later

Continued in next post.....