muttley600

Banned

This thread will deal with all matters relating to tools required for the build and discussions on which ones are essential, nice to have, a waste of time, etc.. It will also cover all those that can be made and options that are available if you can't afford or want to splash out on a whole workshop. You don't have to.. There are more ways to skin a cat than by stuffing it full of cream so to speak.

This thread will be a participation thread so please feel free to discuss or ask and questions in the body of the thread. The build thread when it happens will be moderated to include only information relating to the build with questions directed to a separate thread.

Tools.

You can never have enough tools.. However you do not need an extensive collection of tools to start out. Perhaps the first piece of advice I can give is that you should always buy the very best you can afford. Cheap tools are definitely a false economy. Your tools will last you a lifetime if you choose well and look after them. Cheap tools not only do not last but will often mess up the job you are trying to accomplish or at the very least make it a lot harder to do well. There are some occasions when you can get a decent tool for a lot less than you'd think but if you are not sure or in doubt ask here. Chances are some one has already tried it.

I have 30 years’ worth of tool collecting kicking about in my workshop and going through them to pick out the few essentials is quite a task. What I have done is to break down the task into categories and I'll list those that I consider essential, those that I would be beneficial and those that you can get if you really want or come across them at a good price.

Classification

I have always considered tools to be broken down into distinct categories. There are exceptions and there is a degree of crossover but broadly speaking you can divide woodworking tools into the following, Measuring, marking, clamping, cutting and supporting. That’s how I intend to approach this. I will outline each category and give some examples of what you may need. As I said there will be exceptions that don't fit neatly into each category and this list is in no way exhaustive and I am bound to miss some so just chime in where appropriate. Many will already have a lot of basic tools and many will have some specific tools. If you do, great use them where you want. If you are starting out this will helpfully give you some clear guidelines on what to look for first. Most of the tools I list as essential are in daily use in my workshop and always to hand. My go to tools if you will. I'm sure JCH will also have a similar list which hopefully he can post..

Measuring.

You'll definitely be needing to measure stuff and measure it accurately. Most measuring on a guitar build goes from fractions of an inch or mm to just over a metre. The picture below shows a selection of basic measuring tools I have to hand and use daily.

I also have a bunch of specific scale rules for fret positions, for nut spacing’s etc. You don't need them. You can mark up your own when the time comes. For now get a selection of steel rules.

Essential.

Ideally both metric and imperial. Most are marked both mine are also marked in both eights and tenths of an inch to accommodate US and EU standards.

A one metre steel rule

A one foot steel rule,

A six inch steel rule.

You can often find these cheaply at boot sales, yard sales etc...

Dividers, A good set is a real must for accurately marking and transferring measurements. If you get just one set get the larger style.

Callipers. They don't have to be digital but it is a real bonus if they are. They are not expensive. The little plastic ones in the picture are a few quid or dollars. The digital are only about 10-15 dollars. I'd put the plastic on the must have list and the digital on the beneficial list.

Beneficial

Sliding Set square is on the nice to have list but not essential. ditto the feeler gauges. Pick them up if you see them and you have some spare cash..

The throat callipers are only needed if you are doing graduated tops. Nice to have but not essential. They are expensive and you can make up a substitute quite easily.

Marking.

Marking accurately is also essential. Remember measure twice cut once? Well you also need to mark just once and it needs to be right.

Essential

Squares

You are going to need a few squares in various sizes. I have a load and have just shown the smaller ones here. You'll notice they all look rather old. They are and they are all spot on 90 degrees. I trust them and they will get used ahead of any newer shiny one that’s hanging about.

If you are picking up a square test it before you buy it. Easy to do, just mark a line with it on a square edge and flip the square through 180 degrees and remark. If the lines match up then it's true. If its even slightly out don't get it.

I would say that essential are a 3" and a 9". You can make larger squares above 12" so don't splash out on them unless you want to.

Scribes and knives. As well as soft pencils you will need a scribe and a centre punch for woodwork these can just be old bradles sharpened up. As long as it marks a clean point. At least one sharp marking knife is essential. Later I will cover making one of these from an old hack saw blade. Worth doing as it can be used for everything from marking to veneer cutting. I learned how to make them when I apprenticed and I still use them daily.

Beneficial.

Adjustable bevel.

A real handy tool but not essential.

Marking gauge.

Handy tool if you have one. You can make suitable replacements so not on the essential list.

Cutting

By far the biggest category for us to be concerned with so stay with me.....

Lets start with Planes and knives.

You are going to need to get used to using a plane. Nothing will square up a piece of wood better than a hand plane and if you intend to get good at this you need to get good and setting and sharpening planes.

I just reached out and grabbed a small selection of the ones I have. Of those the most essential is the low angle block plane closely followed by the No.5 (both in the middle row). All planes are nice to have so if you see them in junk sales for a decent price get them. It's a good idea to check they are true and adjustable but those things can be fixed with effort so if not bargain the price down. If you are to splash out on one then get the low angle block plane. In conjunction with our router you will be able to get a real good square edge when needed. The best on the market in our price range are Stanley, look out for Bailey and Record on the second hand market.

You can see a selection of Japanese knives and luthier knives. Not essential but if you see any good steel knives that can be sharpened pick em up. The knife at the top with the wooden stock is the one I will be making..

Chisels..

To start get 1/2" , 1/4" then if budget allows 1" and 3/8"

You should be able to get a decent Stanley set reasonably cheap. Chisels is an area where you really do get what you pay for. I have several hundreds and I always go back to about a dozen or so that hold their edge.

You can often pick up good chisels at junk sales. With work you can polish and grind them to make a really good tool.

The stoning and sharpening needs a post on its own... But I've chucked up a picture of a few of the stones I use. More on that later, chisels need to be sharp.

Saws

This is an area where you are going to have to get a specialized tool if you want to do your own fret slots. JCH is getting a preslotted board so if that’s your option you OK with a decent back saw and maybe a Tenon saw. If you want the slotting saw then you need a .22 kerf saw or the ability to set that yourself.

Files and Rasps.

You will need some or these to get the neck sorted and also to handle template work and finishing edges. You can seek these out second hand as well.

The essential ones would be a half round fine cut rasp and flat fine cut rasp and a flat 6 or 9" fine cut metal file. There are a few other files we will use and adapt when it comes to fretting work. More on them later.

You are going to need a selection of drill bits and a drill. Variable speed is desirable.

The only one that you may not have to hand will be the 12 or 13mm for the bridge posts..

Clamping,

Clamps is something you are going to have to bite the bullet and get some decent ones. The most used ones you will need will be 6 or 9" push up clamps. There are a load of ways of clamping stuff that doesn't require expensive clamps and perhaps the best way to cover that is to describe them as we go. Just look to get a basic set of push up clamps for now. A few pics of clamps below to give you an idea of what can be done and my basic rack of push up clamps..

As an example of what you can do if you need to. The other day I needed a small toggle clamp for a jig. I could find nothing suitable off the shelf so set about making one....

Everything is possible..

This list of tools is not intended to be exhaustive nor is a definitive list. Every tool listed has substitutes and with a little ingenuity you can work around not having them. This is intended a guide to point you in the right place to start. Others will add I'm sure and I will comment on whether I think them suitable of desirable. That’s the beauty of all this there is no one way or one size fits all.

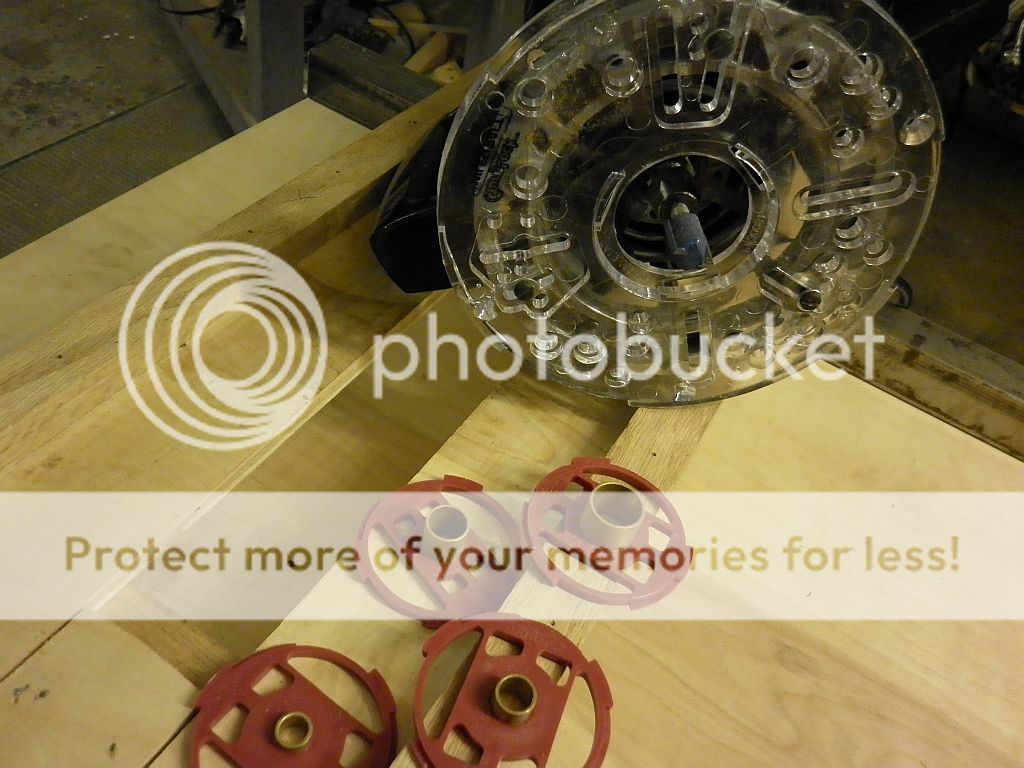

Next I shall move on to the router and some of the bits and attachments you WILL be needing.

This thread will be a participation thread so please feel free to discuss or ask and questions in the body of the thread. The build thread when it happens will be moderated to include only information relating to the build with questions directed to a separate thread.

Tools.

You can never have enough tools.. However you do not need an extensive collection of tools to start out. Perhaps the first piece of advice I can give is that you should always buy the very best you can afford. Cheap tools are definitely a false economy. Your tools will last you a lifetime if you choose well and look after them. Cheap tools not only do not last but will often mess up the job you are trying to accomplish or at the very least make it a lot harder to do well. There are some occasions when you can get a decent tool for a lot less than you'd think but if you are not sure or in doubt ask here. Chances are some one has already tried it.

I have 30 years’ worth of tool collecting kicking about in my workshop and going through them to pick out the few essentials is quite a task. What I have done is to break down the task into categories and I'll list those that I consider essential, those that I would be beneficial and those that you can get if you really want or come across them at a good price.

Classification

I have always considered tools to be broken down into distinct categories. There are exceptions and there is a degree of crossover but broadly speaking you can divide woodworking tools into the following, Measuring, marking, clamping, cutting and supporting. That’s how I intend to approach this. I will outline each category and give some examples of what you may need. As I said there will be exceptions that don't fit neatly into each category and this list is in no way exhaustive and I am bound to miss some so just chime in where appropriate. Many will already have a lot of basic tools and many will have some specific tools. If you do, great use them where you want. If you are starting out this will helpfully give you some clear guidelines on what to look for first. Most of the tools I list as essential are in daily use in my workshop and always to hand. My go to tools if you will. I'm sure JCH will also have a similar list which hopefully he can post..

Measuring.

You'll definitely be needing to measure stuff and measure it accurately. Most measuring on a guitar build goes from fractions of an inch or mm to just over a metre. The picture below shows a selection of basic measuring tools I have to hand and use daily.

I also have a bunch of specific scale rules for fret positions, for nut spacing’s etc. You don't need them. You can mark up your own when the time comes. For now get a selection of steel rules.

Essential.

Ideally both metric and imperial. Most are marked both mine are also marked in both eights and tenths of an inch to accommodate US and EU standards.

A one metre steel rule

A one foot steel rule,

A six inch steel rule.

You can often find these cheaply at boot sales, yard sales etc...

Dividers, A good set is a real must for accurately marking and transferring measurements. If you get just one set get the larger style.

Callipers. They don't have to be digital but it is a real bonus if they are. They are not expensive. The little plastic ones in the picture are a few quid or dollars. The digital are only about 10-15 dollars. I'd put the plastic on the must have list and the digital on the beneficial list.

Beneficial

Sliding Set square is on the nice to have list but not essential. ditto the feeler gauges. Pick them up if you see them and you have some spare cash..

The throat callipers are only needed if you are doing graduated tops. Nice to have but not essential. They are expensive and you can make up a substitute quite easily.

Marking.

Marking accurately is also essential. Remember measure twice cut once? Well you also need to mark just once and it needs to be right.

Essential

Squares

You are going to need a few squares in various sizes. I have a load and have just shown the smaller ones here. You'll notice they all look rather old. They are and they are all spot on 90 degrees. I trust them and they will get used ahead of any newer shiny one that’s hanging about.

If you are picking up a square test it before you buy it. Easy to do, just mark a line with it on a square edge and flip the square through 180 degrees and remark. If the lines match up then it's true. If its even slightly out don't get it.

I would say that essential are a 3" and a 9". You can make larger squares above 12" so don't splash out on them unless you want to.

Scribes and knives. As well as soft pencils you will need a scribe and a centre punch for woodwork these can just be old bradles sharpened up. As long as it marks a clean point. At least one sharp marking knife is essential. Later I will cover making one of these from an old hack saw blade. Worth doing as it can be used for everything from marking to veneer cutting. I learned how to make them when I apprenticed and I still use them daily.

Beneficial.

Adjustable bevel.

A real handy tool but not essential.

Marking gauge.

Handy tool if you have one. You can make suitable replacements so not on the essential list.

Cutting

By far the biggest category for us to be concerned with so stay with me.....

Lets start with Planes and knives.

You are going to need to get used to using a plane. Nothing will square up a piece of wood better than a hand plane and if you intend to get good at this you need to get good and setting and sharpening planes.

I just reached out and grabbed a small selection of the ones I have. Of those the most essential is the low angle block plane closely followed by the No.5 (both in the middle row). All planes are nice to have so if you see them in junk sales for a decent price get them. It's a good idea to check they are true and adjustable but those things can be fixed with effort so if not bargain the price down. If you are to splash out on one then get the low angle block plane. In conjunction with our router you will be able to get a real good square edge when needed. The best on the market in our price range are Stanley, look out for Bailey and Record on the second hand market.

You can see a selection of Japanese knives and luthier knives. Not essential but if you see any good steel knives that can be sharpened pick em up. The knife at the top with the wooden stock is the one I will be making..

Chisels..

To start get 1/2" , 1/4" then if budget allows 1" and 3/8"

You should be able to get a decent Stanley set reasonably cheap. Chisels is an area where you really do get what you pay for. I have several hundreds and I always go back to about a dozen or so that hold their edge.

You can often pick up good chisels at junk sales. With work you can polish and grind them to make a really good tool.

The stoning and sharpening needs a post on its own... But I've chucked up a picture of a few of the stones I use. More on that later, chisels need to be sharp.

Saws

This is an area where you are going to have to get a specialized tool if you want to do your own fret slots. JCH is getting a preslotted board so if that’s your option you OK with a decent back saw and maybe a Tenon saw. If you want the slotting saw then you need a .22 kerf saw or the ability to set that yourself.

Files and Rasps.

You will need some or these to get the neck sorted and also to handle template work and finishing edges. You can seek these out second hand as well.

The essential ones would be a half round fine cut rasp and flat fine cut rasp and a flat 6 or 9" fine cut metal file. There are a few other files we will use and adapt when it comes to fretting work. More on them later.

You are going to need a selection of drill bits and a drill. Variable speed is desirable.

The only one that you may not have to hand will be the 12 or 13mm for the bridge posts..

Clamping,

Clamps is something you are going to have to bite the bullet and get some decent ones. The most used ones you will need will be 6 or 9" push up clamps. There are a load of ways of clamping stuff that doesn't require expensive clamps and perhaps the best way to cover that is to describe them as we go. Just look to get a basic set of push up clamps for now. A few pics of clamps below to give you an idea of what can be done and my basic rack of push up clamps..

As an example of what you can do if you need to. The other day I needed a small toggle clamp for a jig. I could find nothing suitable off the shelf so set about making one....

Everything is possible..

This list of tools is not intended to be exhaustive nor is a definitive list. Every tool listed has substitutes and with a little ingenuity you can work around not having them. This is intended a guide to point you in the right place to start. Others will add I'm sure and I will comment on whether I think them suitable of desirable. That’s the beauty of all this there is no one way or one size fits all.

Next I shall move on to the router and some of the bits and attachments you WILL be needing.

Last edited:

In the mean time here is a shot of a few made from old saw blades.. The triangular file shaped tool is a burnisher made from an old file ground clean and polished. Look out for an old 6" round file or triangular file at a junk sale and snag it. You will need one when the time comes... Should cost coppers but the steel needs to be old and hard..

In the mean time here is a shot of a few made from old saw blades.. The triangular file shaped tool is a burnisher made from an old file ground clean and polished. Look out for an old 6" round file or triangular file at a junk sale and snag it. You will need one when the time comes... Should cost coppers but the steel needs to be old and hard..