sweetbeats

Reel deep thoughts...

First of all, I don't know where this will go in the long-run...this is about the Ampex 440C "basket-case" that I have that came into my possession as a result of the events detailed in this thread, and about which I recently spoke in of this thread.

The reason I don't know for sure where it is going to go is because its going to take a lot of work, and I already have a halftrack, my Tascam BR-20T.

I've been desparate to try and clear stuff out but I always feel conflicted about this one, and the pictorial content below will probably explain why; its a pretty complete package in the end, with spares and room to grow.

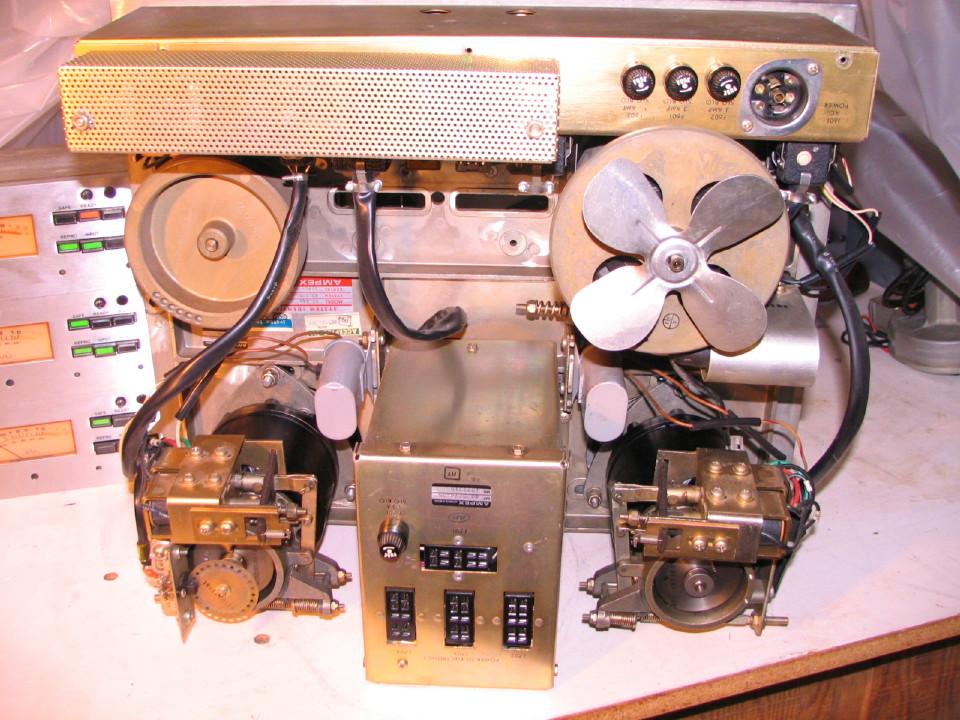

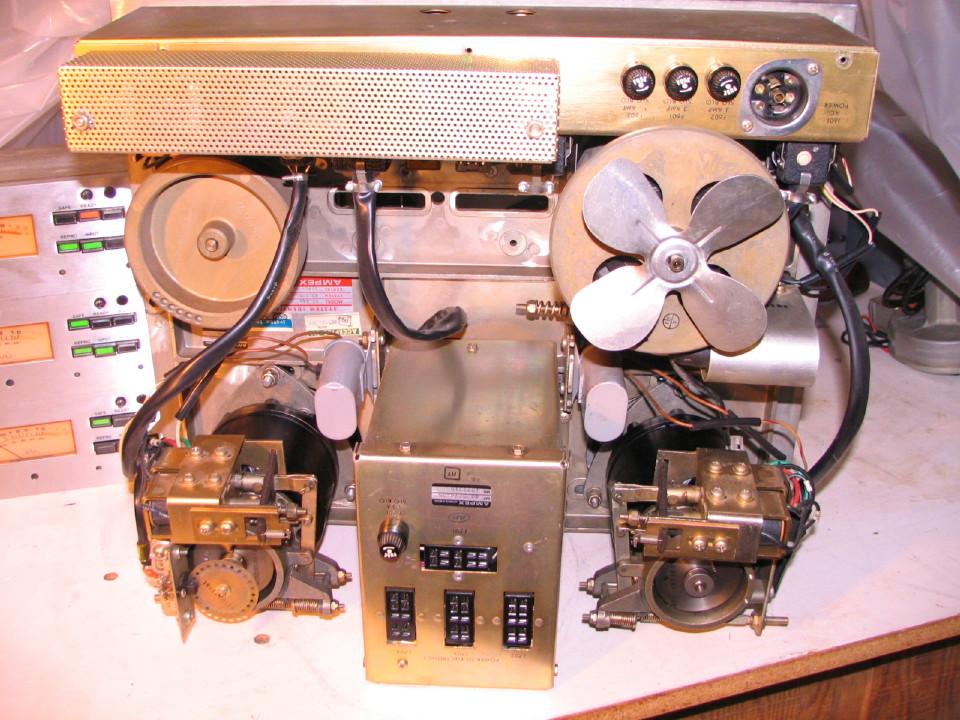

First of all, here's the transport. You'll notice there's no headblock. That's probably the biggest issue though more on that below. Overall it is very straight and clean...the bearings are good, pinch roller is excellent and I have an upgrade for it as well. The scrape flutter idler is there and in good shape. Needs new reel corks but I have those already, and I have a neat upgrade for the reel adapters...more on that below too. Here it is...yeah, I know its upside down...the proper way to store it when not in a rack because the power supply is a better "stand" than the transport control box:

Those that know Ampex machines will notice that the capstan motor is the AC Hysteresis Sync motor as opposed to the DC Servo version, which was optional on the 'B' models but standard on the 'C' models...so I have a 'C' with an "optional" AC capstan motor. But I DO have a complete functional DC assembly...the motor and power supply from a spare 'B' transport. So...I plan on putting that on the 'C':

Now, any machine like this needs something in which to mount, and I do have a proper Ampex roll-around for it...very dirty at the moment, and it will need a new cooling fan, but under all the dust and grime it is a very straight and healthy console. And I do have the rest of the hardware and risers and such for the rest of the machine, all in very good condition:

Related to the console I also have the hard-to-find "belly panel" that goes in the front underneath the transport when mounted in the console...this one even has the original captive screws:

And this is a silly thing but the transport contol box cover that came with the 'C' is missing some of the printed silk-screening regarding the tension resistors...I have this spare. Can't even remember where I got it but it is in nearly mint condition:

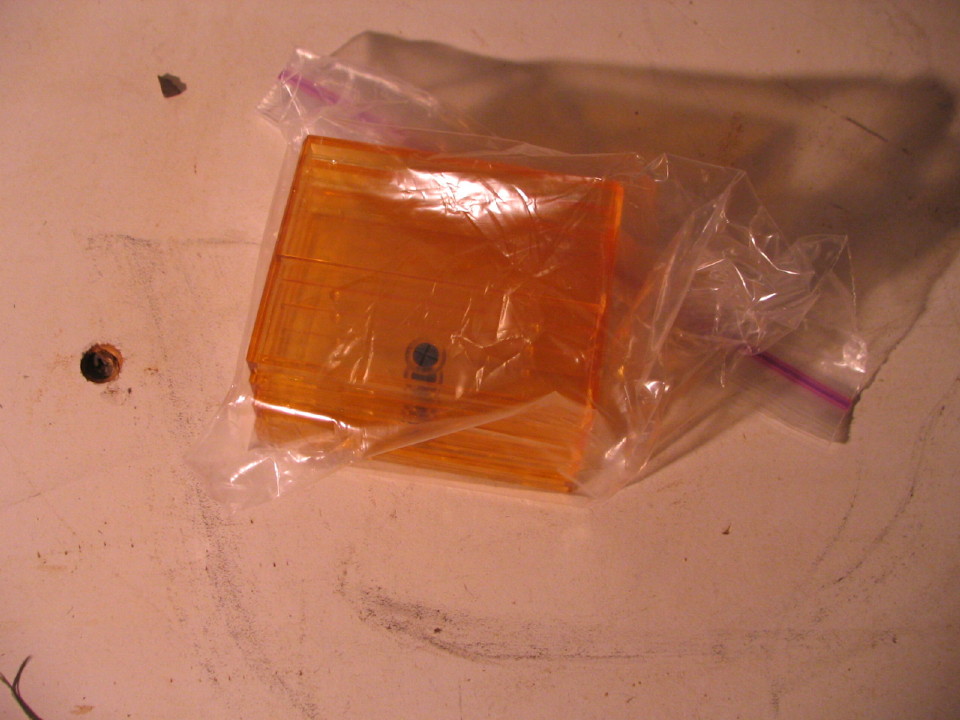

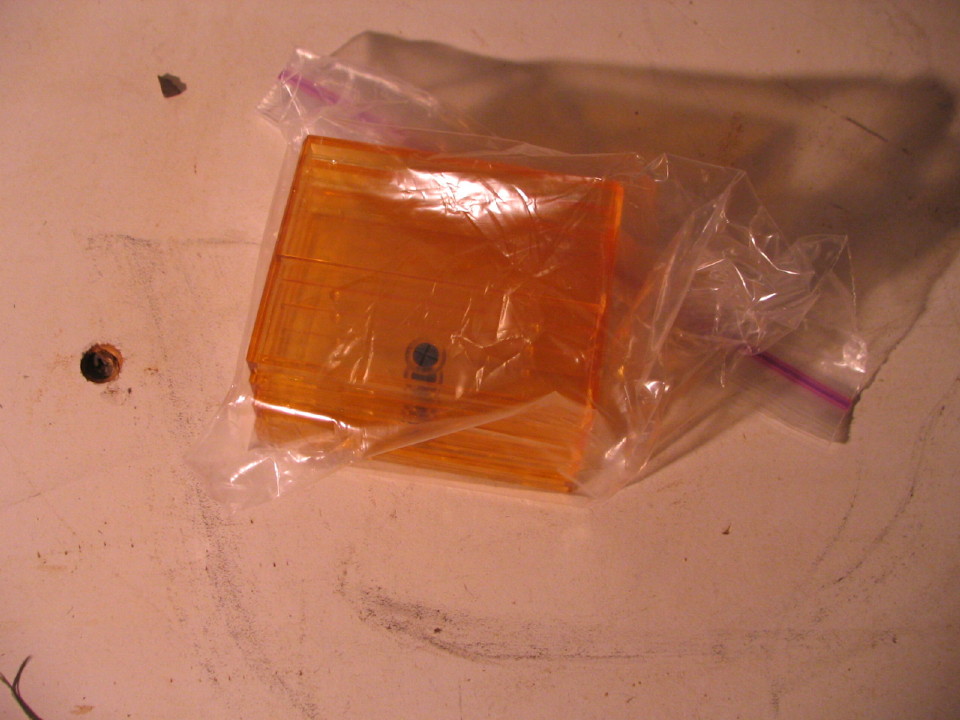

And electronics modules I have, yes. Three complete units, and a couple partial parts-donor units. I even have VGC stainless cover panels for the cardbays, and this is another kind of silly-inconsequential thing but I have NOS meter lenses too:

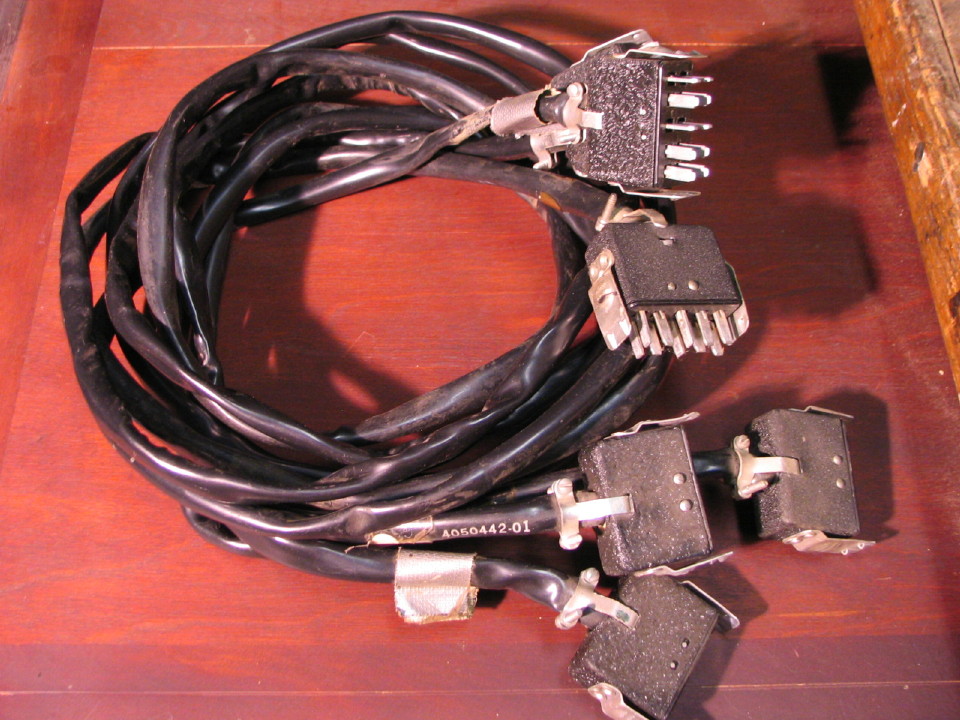

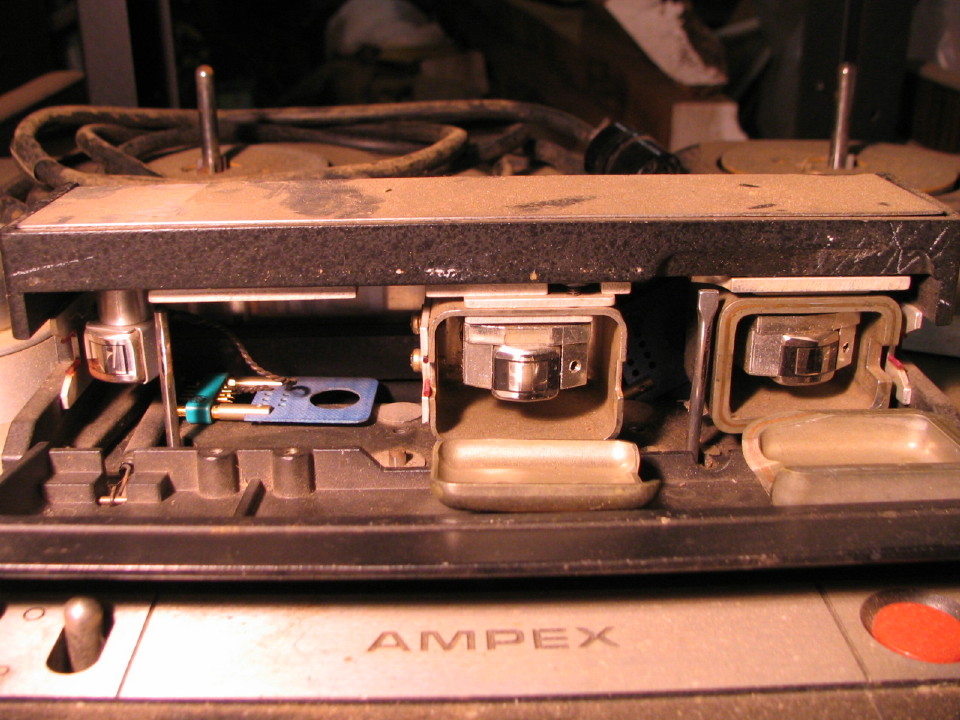

You may have noticed that the head-cable box was missing in the pic of the transport...no fear...got one:

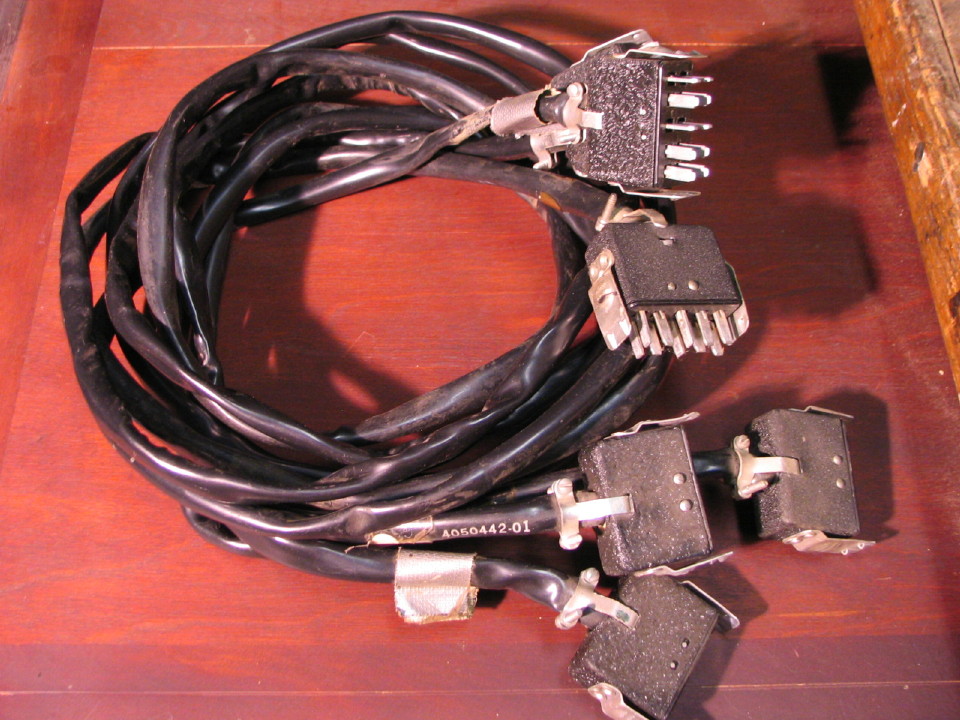

And cables to connect the electronics to the power supply? Got 'em:

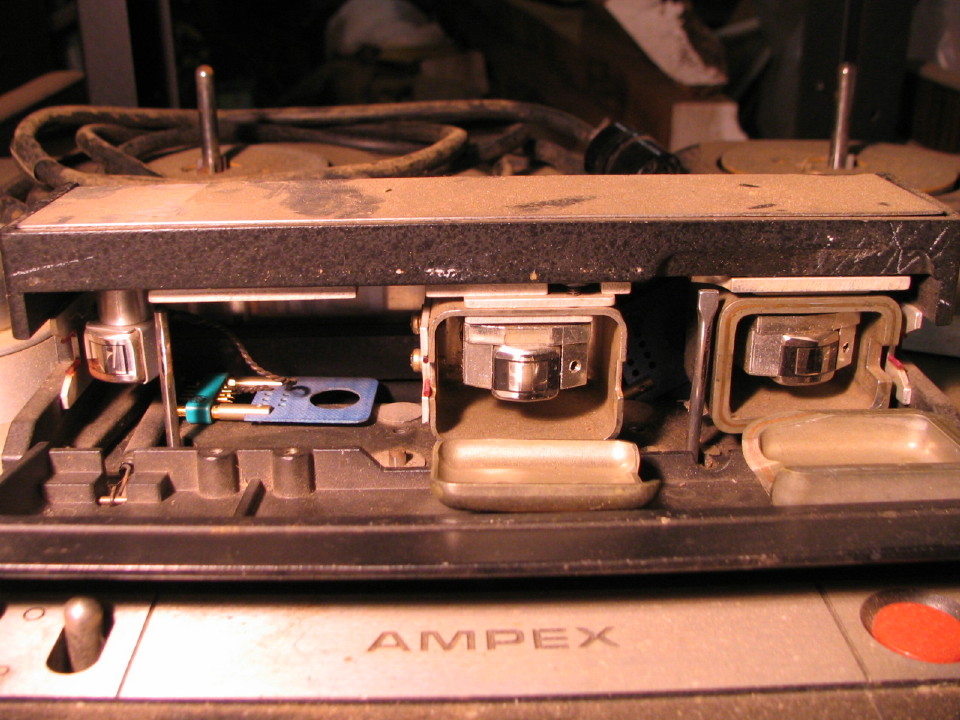

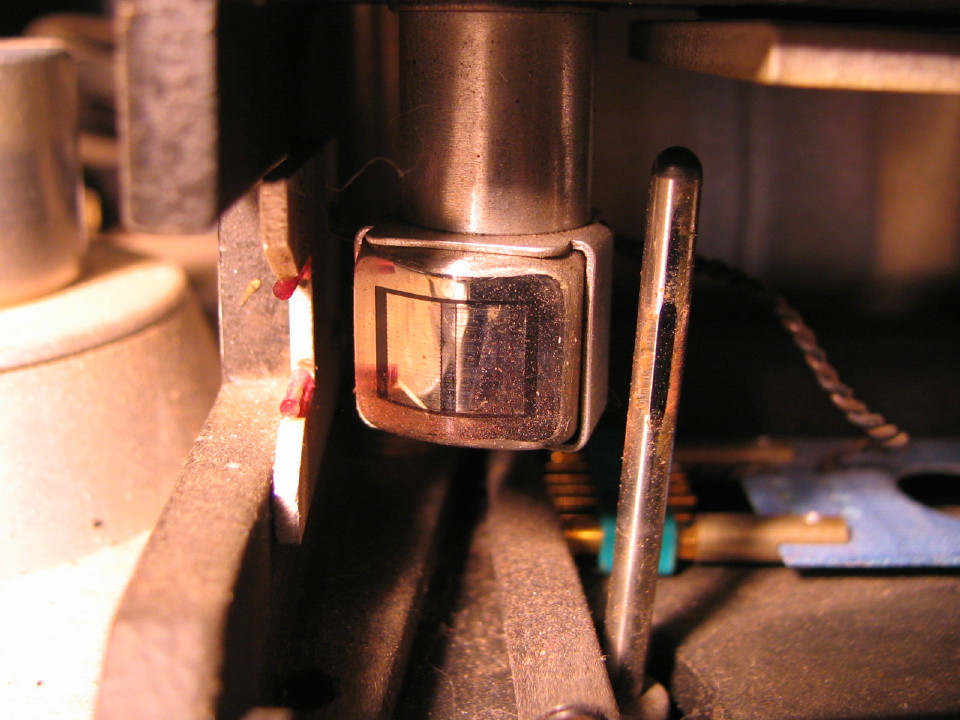

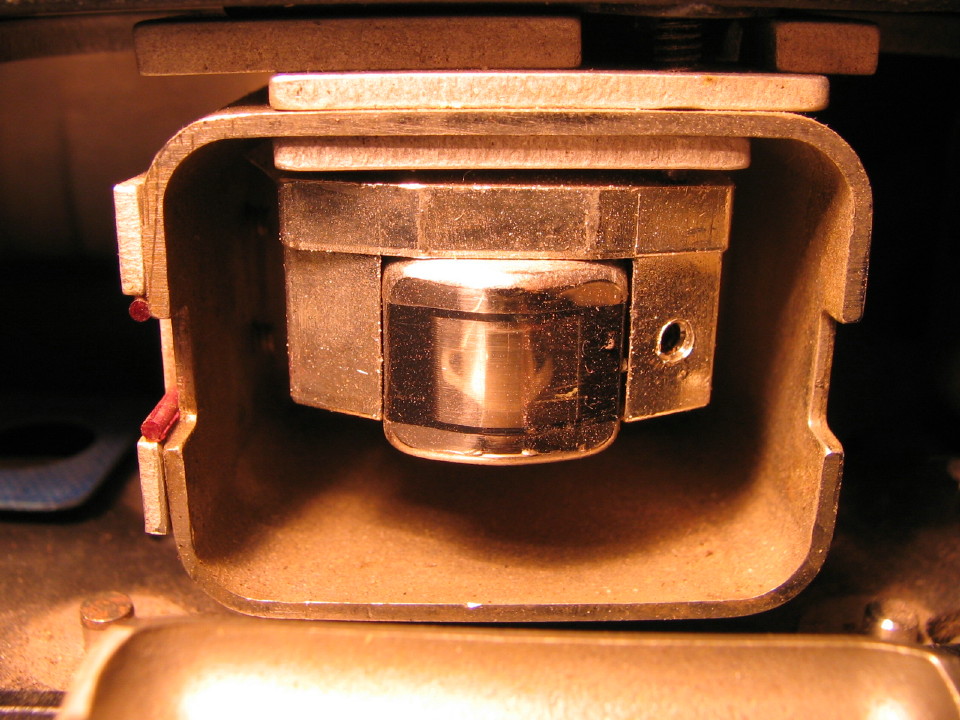

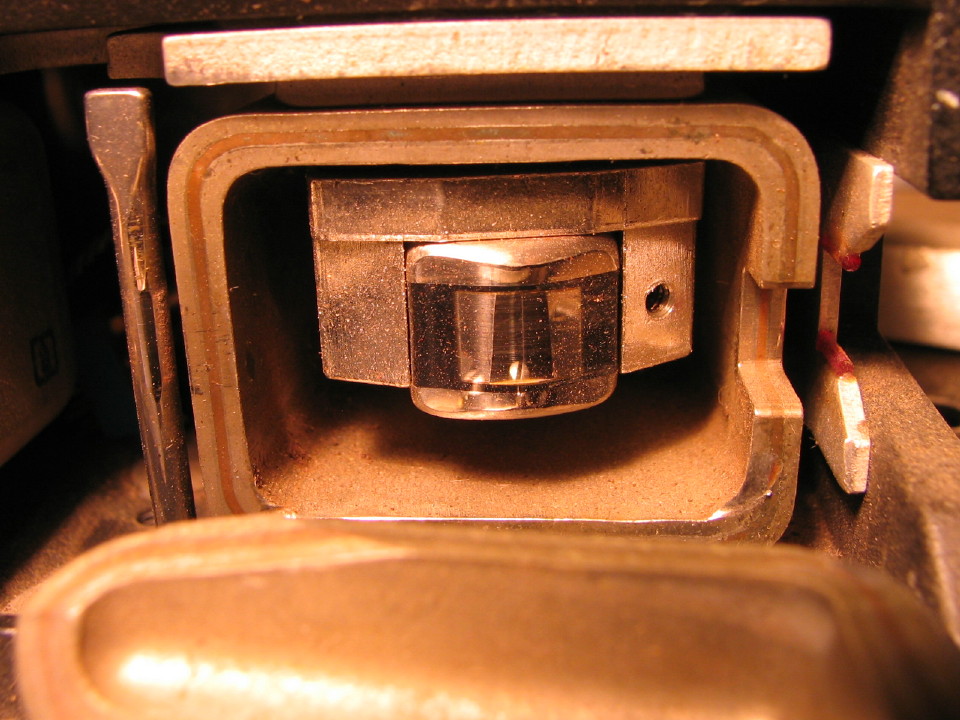

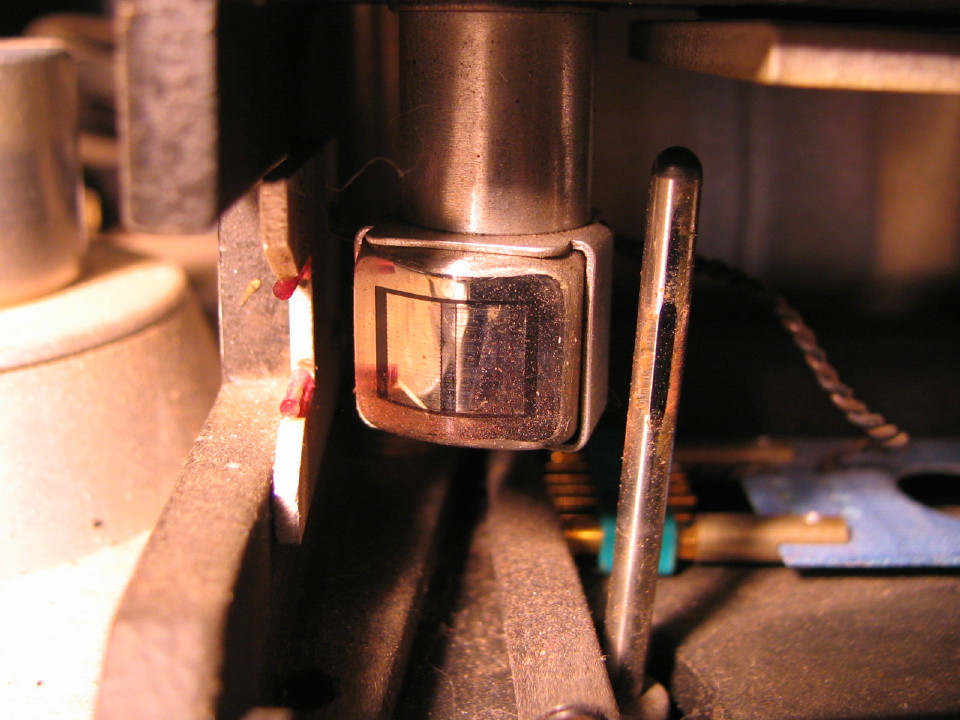

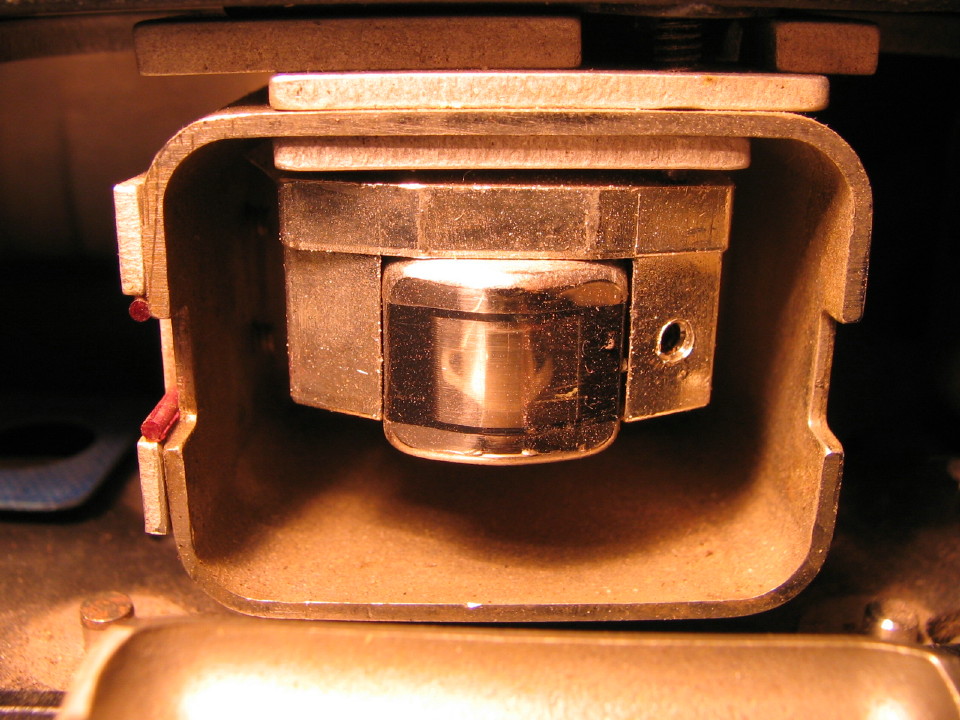

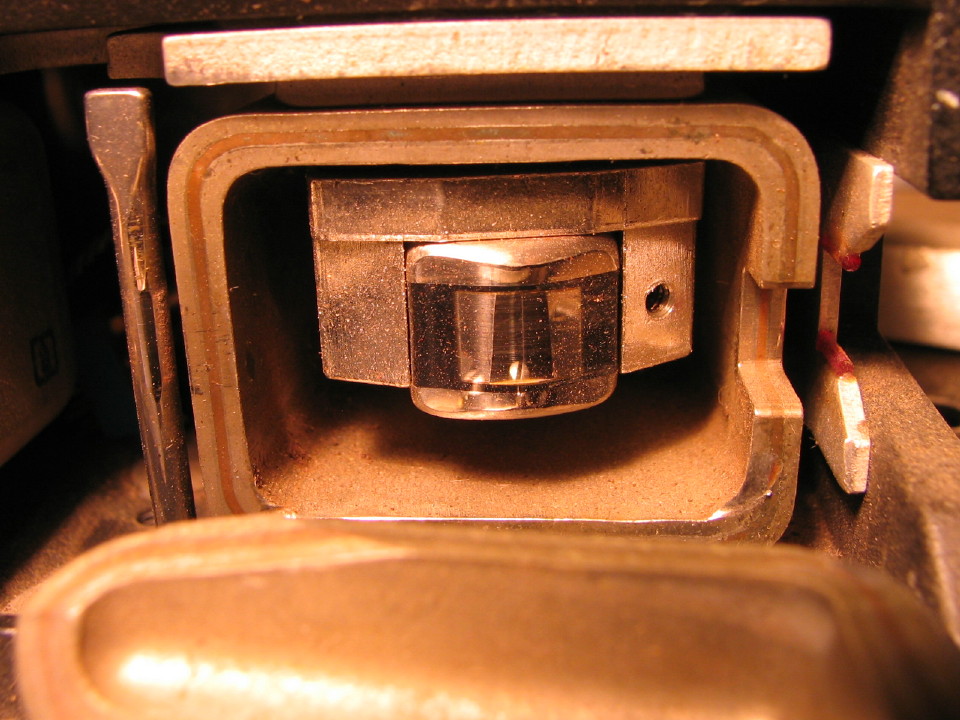

So back to the transport...the headblock or "head nest" as it is sometimes called...I DO have one but it is loaded with full-track heads...better than nothing, but the play head is badly keystoned. At any rate, it is complete, should clean up nice, and it is proper 440C as it has the ruby guides. One important piece of the picture here is that it isn't a 1/4" block...it is a 1/2" block (in which you can place 1/4" heads like what's in there...there is a factory spacer kit)...so if ever I DO decide to go crazy and purchase used or new 1/2" halftrack heads and guides and cans I've got the proper block for it. Here it is...the individual pics of the heads are in order of erase, record and play:

1/2" halftrack heads and guides and cans I've got the proper block for it. Here it is...the individual pics of the heads are in order of erase, record and play:

Other fun bits for the transport include a premium pinch roller with cartridge bearings (will need a rebuild but...), and a brand-new set of reel table corks:

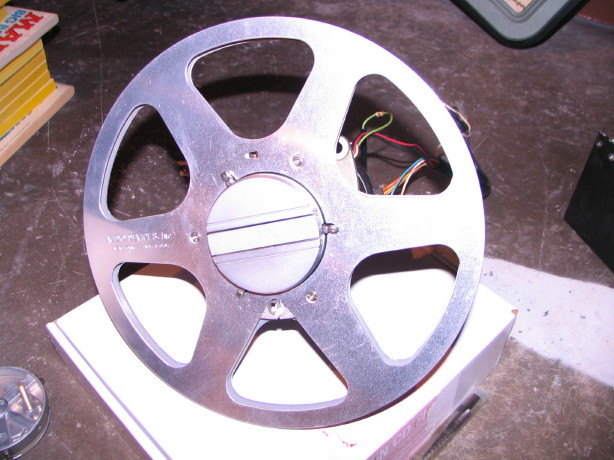

And now for the bit about the reel adapters, and this includes what I consider to be an upgrade for the brakes too...I'd be using the reel motors that came out of my 440-8 that I parted out. Why? The brakes are a solid drum type as also found on the original "A" version of the AG-440. I consider it an upgrade because the standard 'B' and 'C' brake drums have a sprague clutch bearing in them...freewheel in one direction and lock in the other...or when they get old they freewheel in both directions...tape all over the place. I think VXB.com may have replacement bearings for the those one-way drums but I prefer the simple type. And the other reason? That's the reel adapter bit...the 440-8 instrumentation type reel adapters. The shafts are different on the 440-8 motors to accomodate the instrumentation type adapters. I love the look of these, and it turns out that when you take out the spacer that goes between the reel table and the adapter on the 440-8, the adapter is just right to clamp a 1/4" reel. One of the motors is already rebuilt (cleaned with new bearings, shaft straightened and brake drum polished). I'll have to execute a small mod to the reel adapter, but otherwise it'd be slick and a simple "bolt-on" upgrade. Here is the motor I have rebuilt and the adapter that has been cleaned up:

I even have a new set of the two main caps that go in the power supply for the recap/upgrade for that unit. These caps are getting hard to find. The big one is on back-order from Mouser, and is about $50. With some help I got these for $17 each (there are also two sets in that box for the other two supplies in the MM-1000):

With some help I got these for $17 each (there are also two sets in that box for the other two supplies in the MM-1000):

OH! And we cannot forget the remote:

So, I'm sure you all can see why I haven't been able to part with this one...and when you consider that the incremental cost of all the above bits was likely less than $100, its a sticky one.

Don't know when I'll be posting any updates, but as I'm going through and selling stuff I've had my hands on this stuff more than once, and just thought it dseserved a thread.

The reason I don't know for sure where it is going to go is because its going to take a lot of work, and I already have a halftrack, my Tascam BR-20T.

I've been desparate to try and clear stuff out but I always feel conflicted about this one, and the pictorial content below will probably explain why; its a pretty complete package in the end, with spares and room to grow.

First of all, here's the transport. You'll notice there's no headblock. That's probably the biggest issue though more on that below. Overall it is very straight and clean...the bearings are good, pinch roller is excellent and I have an upgrade for it as well. The scrape flutter idler is there and in good shape. Needs new reel corks but I have those already, and I have a neat upgrade for the reel adapters...more on that below too. Here it is...yeah, I know its upside down...the proper way to store it when not in a rack because the power supply is a better "stand" than the transport control box:

Those that know Ampex machines will notice that the capstan motor is the AC Hysteresis Sync motor as opposed to the DC Servo version, which was optional on the 'B' models but standard on the 'C' models...so I have a 'C' with an "optional" AC capstan motor. But I DO have a complete functional DC assembly...the motor and power supply from a spare 'B' transport. So...I plan on putting that on the 'C':

Now, any machine like this needs something in which to mount, and I do have a proper Ampex roll-around for it...very dirty at the moment, and it will need a new cooling fan, but under all the dust and grime it is a very straight and healthy console. And I do have the rest of the hardware and risers and such for the rest of the machine, all in very good condition:

Related to the console I also have the hard-to-find "belly panel" that goes in the front underneath the transport when mounted in the console...this one even has the original captive screws:

And this is a silly thing but the transport contol box cover that came with the 'C' is missing some of the printed silk-screening regarding the tension resistors...I have this spare. Can't even remember where I got it but it is in nearly mint condition:

And electronics modules I have, yes. Three complete units, and a couple partial parts-donor units. I even have VGC stainless cover panels for the cardbays, and this is another kind of silly-inconsequential thing but I have NOS meter lenses too:

You may have noticed that the head-cable box was missing in the pic of the transport...no fear...got one:

And cables to connect the electronics to the power supply? Got 'em:

So back to the transport...the headblock or "head nest" as it is sometimes called...I DO have one but it is loaded with full-track heads...better than nothing, but the play head is badly keystoned. At any rate, it is complete, should clean up nice, and it is proper 440C as it has the ruby guides. One important piece of the picture here is that it isn't a 1/4" block...it is a 1/2" block (in which you can place 1/4" heads like what's in there...there is a factory spacer kit)...so if ever I DO decide to go crazy and purchase used or new

1/2" halftrack heads and guides and cans I've got the proper block for it. Here it is...the individual pics of the heads are in order of erase, record and play:

1/2" halftrack heads and guides and cans I've got the proper block for it. Here it is...the individual pics of the heads are in order of erase, record and play:

Other fun bits for the transport include a premium pinch roller with cartridge bearings (will need a rebuild but...), and a brand-new set of reel table corks:

And now for the bit about the reel adapters, and this includes what I consider to be an upgrade for the brakes too...I'd be using the reel motors that came out of my 440-8 that I parted out. Why? The brakes are a solid drum type as also found on the original "A" version of the AG-440. I consider it an upgrade because the standard 'B' and 'C' brake drums have a sprague clutch bearing in them...freewheel in one direction and lock in the other...or when they get old they freewheel in both directions...tape all over the place. I think VXB.com may have replacement bearings for the those one-way drums but I prefer the simple type. And the other reason? That's the reel adapter bit...the 440-8 instrumentation type reel adapters. The shafts are different on the 440-8 motors to accomodate the instrumentation type adapters. I love the look of these, and it turns out that when you take out the spacer that goes between the reel table and the adapter on the 440-8, the adapter is just right to clamp a 1/4" reel. One of the motors is already rebuilt (cleaned with new bearings, shaft straightened and brake drum polished). I'll have to execute a small mod to the reel adapter, but otherwise it'd be slick and a simple "bolt-on" upgrade. Here is the motor I have rebuilt and the adapter that has been cleaned up:

I even have a new set of the two main caps that go in the power supply for the recap/upgrade for that unit. These caps are getting hard to find. The big one is on back-order from Mouser, and is about $50.

With some help I got these for $17 each (there are also two sets in that box for the other two supplies in the MM-1000):

With some help I got these for $17 each (there are also two sets in that box for the other two supplies in the MM-1000):

OH! And we cannot forget the remote:

So, I'm sure you all can see why I haven't been able to part with this one...and when you consider that the incremental cost of all the above bits was likely less than $100, its a sticky one.

Don't know when I'll be posting any updates, but as I'm going through and selling stuff I've had my hands on this stuff more than once, and just thought it dseserved a thread.