lo.fi.love

Functionally obsessed.

Hey folks,

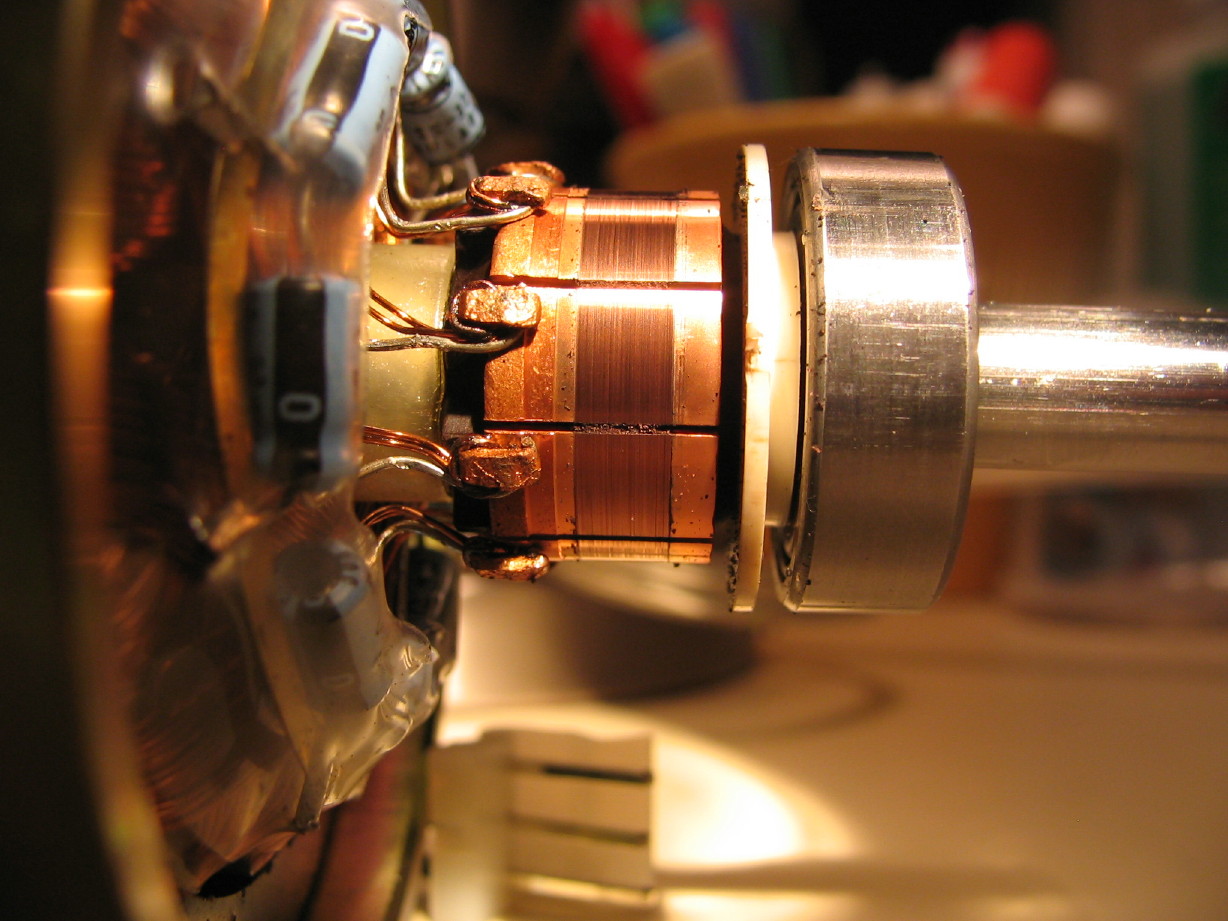

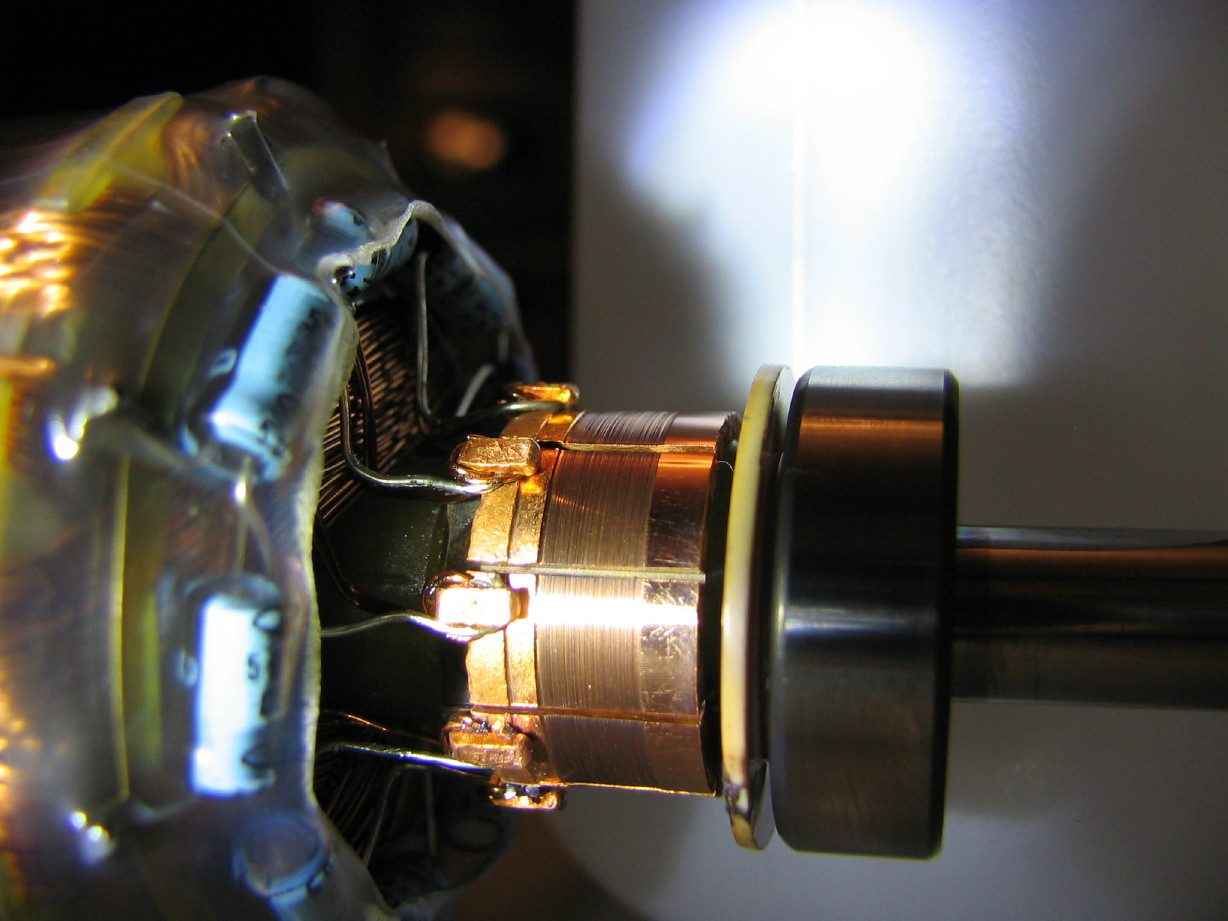

I'm restoring a 'parts deck'. One thing that's wrong with it is that the reel motors slow down when I FF, RW, or play a tape.

It's not the tape itself, so there's no SSS going on here.

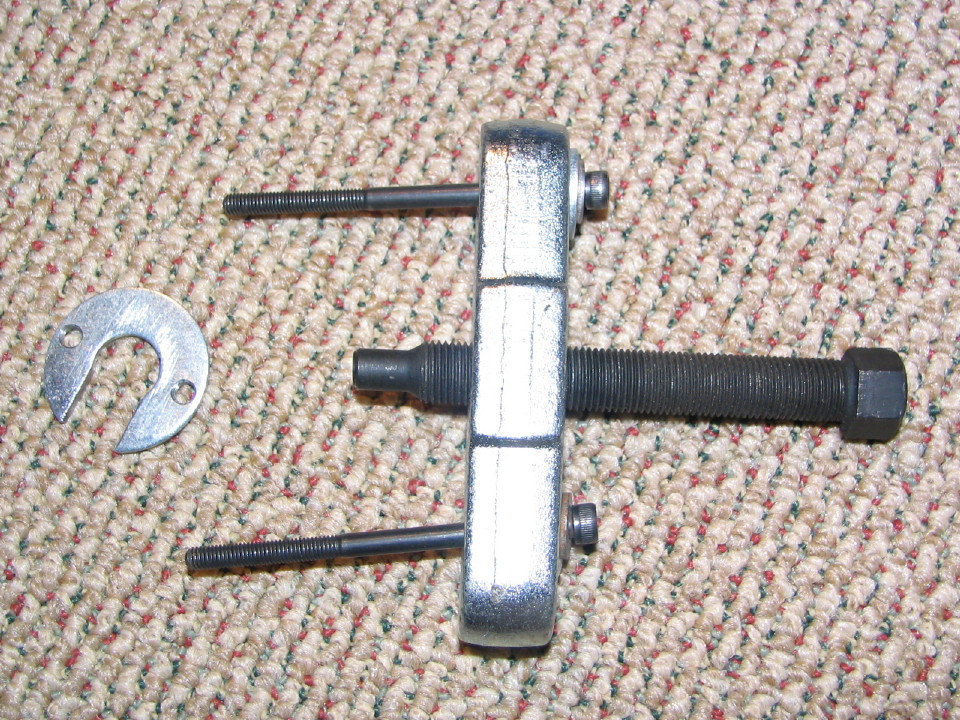

I'm inclined to remove the reel motors to open and inspect them. My experience with bicycles lends me to believe that the motors just need to be cleaned out and the bearings repacked with grease. Does this sound right to anyone?

If so, what kind of grease should I use? Lithium grease?

I'll really appreciate your help! Thanks!

I'm restoring a 'parts deck'. One thing that's wrong with it is that the reel motors slow down when I FF, RW, or play a tape.

It's not the tape itself, so there's no SSS going on here.

I'm inclined to remove the reel motors to open and inspect them. My experience with bicycles lends me to believe that the motors just need to be cleaned out and the bearings repacked with grease. Does this sound right to anyone?

If so, what kind of grease should I use? Lithium grease?

I'll really appreciate your help! Thanks!