R

reelshows

New member

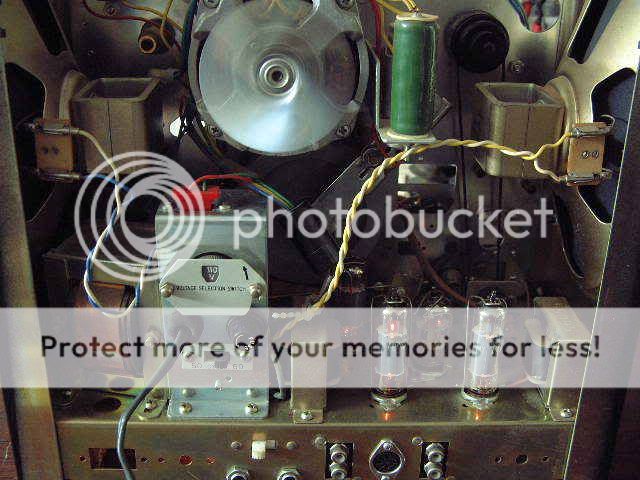

I'm brand new, first post. I recorded for years on reel to reel. I have a stack of tapes about 10 feet high. Only one of my old recorders is usable, would like to repair my 1700. The motor turns only when spun by hand, and then stops when put under a load. Could this be the capacitor? Or the Motor?

I really need to get something else working, the one that is usable(sony tc-270) has a small rewind problem after it heats up(Belt?).

Any help will be appreciated.

I really need to get something else working, the one that is usable(sony tc-270) has a small rewind problem after it heats up(Belt?).

Any help will be appreciated.