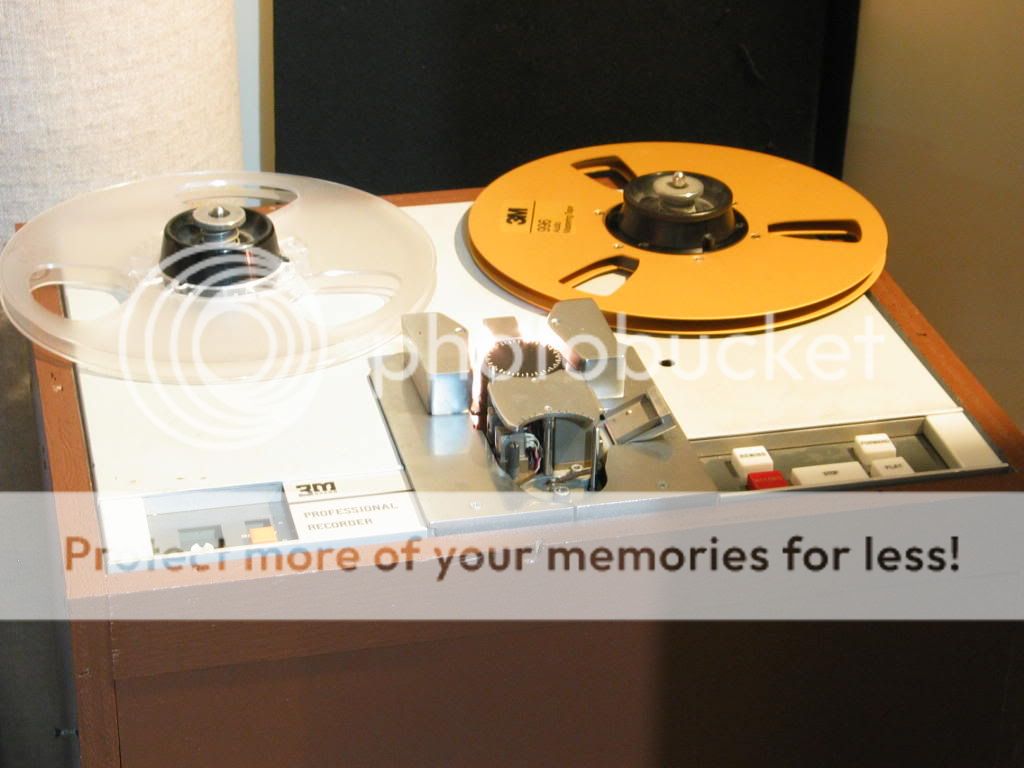

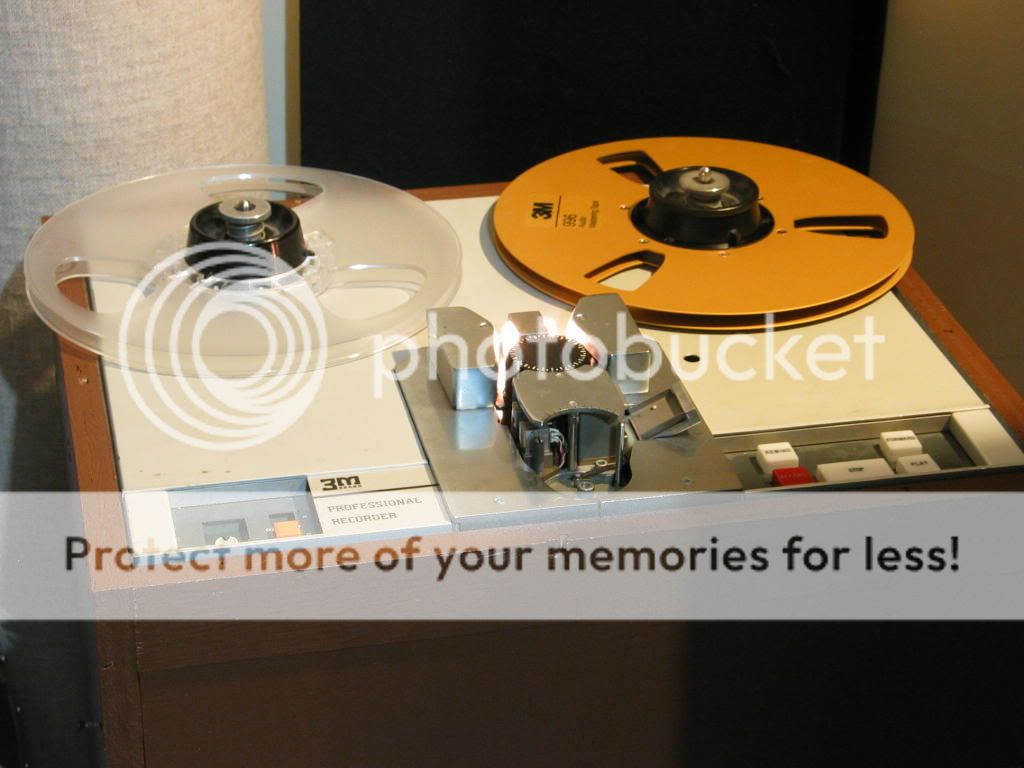

I thought I'd start a new thread in case we have more discussion on the M-23, since the previous thread started out as an info item on the labeling of tape channels and the tracks they correspond to on the tape.

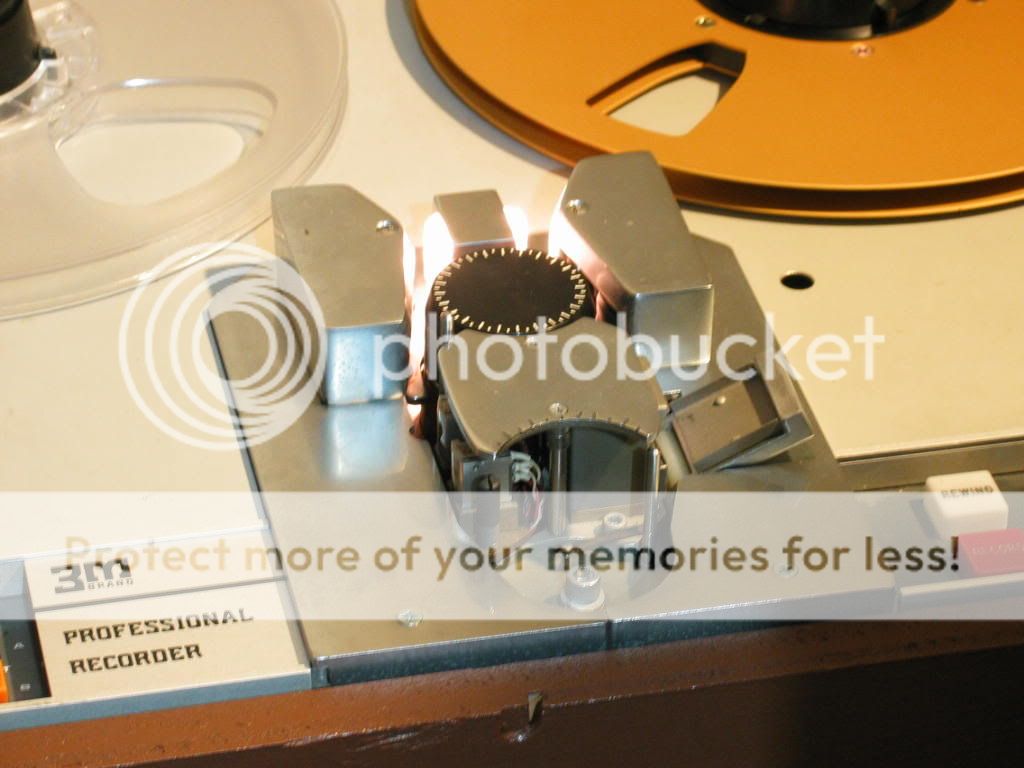

I'm a bit concerned about the idler. I took it off and tested it and it has a fair amount of wobble. It may be repairable, but I'm not sure. I was able to get the machine working a bit better by rotating the idler base to the most favorable angle, but that wobble may produce a flutter issue and may also affect the bearing lifetime, so it's better to fix or replace, I think.

This is one of those times when I will seek counsel from Dale Manquen, a former 3M employee, who is a real expert on these machines. I hope the idler can be repaired. Otherwise, I'll need to contact Matt Allen, since he is the keeper of the main store of NOS 3M parts.

Cheers,

Otto

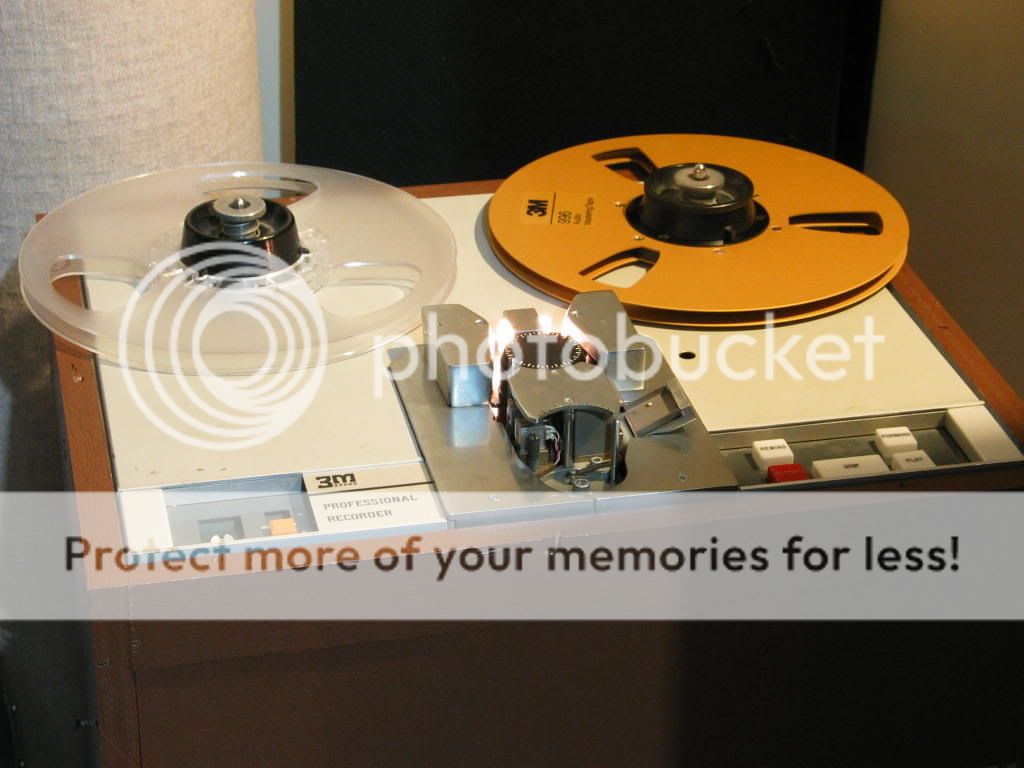

I'm a bit concerned about the idler. I took it off and tested it and it has a fair amount of wobble. It may be repairable, but I'm not sure. I was able to get the machine working a bit better by rotating the idler base to the most favorable angle, but that wobble may produce a flutter issue and may also affect the bearing lifetime, so it's better to fix or replace, I think.

This is one of those times when I will seek counsel from Dale Manquen, a former 3M employee, who is a real expert on these machines. I hope the idler can be repaired. Otherwise, I'll need to contact Matt Allen, since he is the keeper of the main store of NOS 3M parts.

Cheers,

Otto

Likely cheaper than the machine shop route and genuine to boot!

Likely cheaper than the machine shop route and genuine to boot!

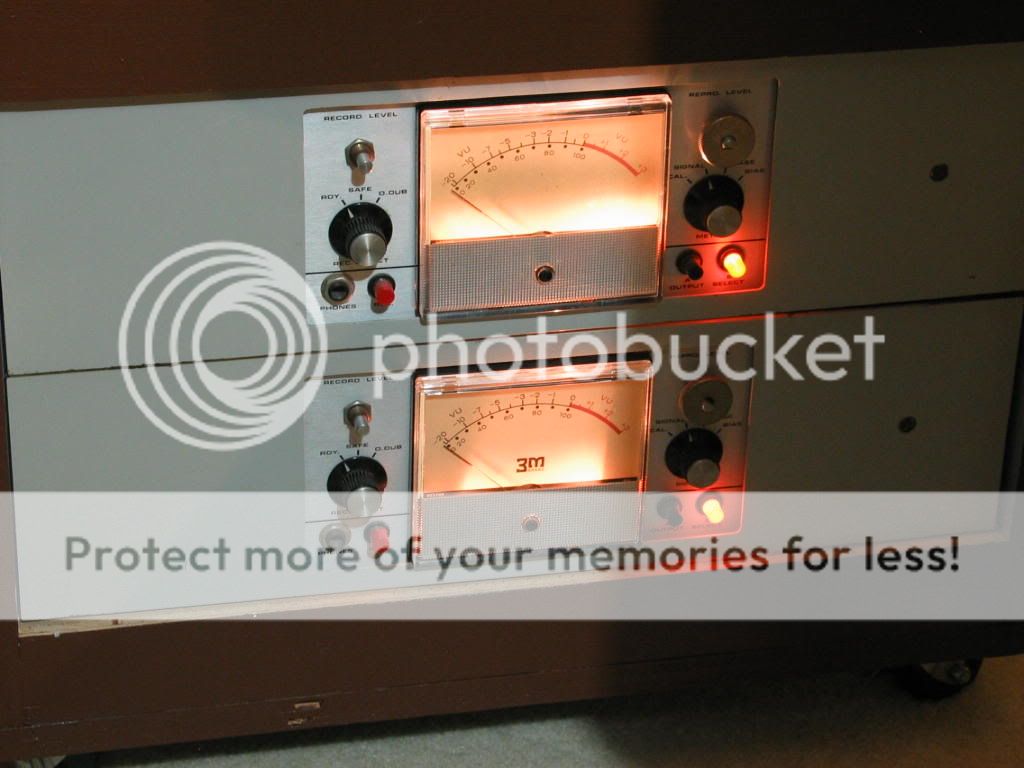

Now it's set where it should be and the levels all match.

Now it's set where it should be and the levels all match.