crazydoc

Master Baiter

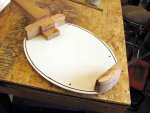

This is a guitar I made earlier this year.

I was in the shop, thinking about materials for my next guitar, when I beheld this beauty sitting on a pile of junk. Eureka! I had replaced it a year ago due to a crack across it from too many uses by my fat ass, but since I seldom throw anything away, there it was waiting for a better life.

I was in the shop, thinking about materials for my next guitar, when I beheld this beauty sitting on a pile of junk. Eureka! I had replaced it a year ago due to a crack across it from too many uses by my fat ass, but since I seldom throw anything away, there it was waiting for a better life.