crazydoc

Master Baiter

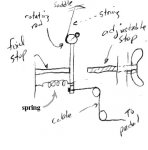

Today, while packing to move, I came across this photo of a pedal steel I built (in my appartment in Sacramento) about 35 years ago, using a Fender lap steel. When I moved to Southern CA I took it with me, but it wouldn't fit into the next move so I gave it to an old guy across the street in 1974.

I used it to record on a song or two - it didn't sound half bad as I remember (though it's on 1/4" reel to reel tape, and I have nothing to play it on anymore.)

Anyway, thought I'd post this for a laff - wish I still had the Fender, though.

I used it to record on a song or two - it didn't sound half bad as I remember (though it's on 1/4" reel to reel tape, and I have nothing to play it on anymore.)

Anyway, thought I'd post this for a laff - wish I still had the Fender, though.