Hey everyone - i'm getting ready to buy my first pair of monitors (adam a7s), but i obviously want to treat my room to get the most out of them at the same time.

i'm going to diy the treatment myself (which i have some experience with), but i had a question about the relationship between corner trap dimensions, coverage, and effectiveness.

I plan on making corner traps out of 703 or an equivalent material, by cutting it into triangles and stacking them together to make a "superchunk" style trap. i'm not sure how deep to make these triangles though.

using a typical 2'x4'x2" panel of 703, i could cut it into 4 or 8 triangles. This would create triangles of dimensions 24"x24"x34" (which has a depth from the face to the corner of 17") - or - 17"x17"x24" (which has a depth from the face to the corner of 12"), respectively. (if this is a bit confusing the way i wrote it, i can try to post some drawings of my ideas)

Which would be more effective? Creating deeper superchunks to fill the corners, or having twice as much corner coverage (or more money to spend treating other areas of the room)?

I do want to add more (non-corner based) bass traps - probably 4" thick 703 panels - as funds permit.

Also, besides this treatment, I have two framed 2'x4'x5" panels consisting of a two 1" 703 panel sandwiching a 3" air gap, which I plan on using at the first reflection point. Also, I have four 8'x2'x1" panels of framed 703 hinged together accordian style to act as a gobo to change the reflectiveness of areas as needed. Additionally, I plan on eventually adding a krk ergo to compensate for the problems inherent in the less than ideal (read: symmetrical) situation i currently have to work with (living in an apartment, unable to create permanent installations). Any advice/criticism/etc. of my plans would be greatly appreciated.

Sorry for the lengthy post - I just wanted to be clear!

Thanks in advance for your help and time!

-Mike

i'm going to diy the treatment myself (which i have some experience with), but i had a question about the relationship between corner trap dimensions, coverage, and effectiveness.

I plan on making corner traps out of 703 or an equivalent material, by cutting it into triangles and stacking them together to make a "superchunk" style trap. i'm not sure how deep to make these triangles though.

using a typical 2'x4'x2" panel of 703, i could cut it into 4 or 8 triangles. This would create triangles of dimensions 24"x24"x34" (which has a depth from the face to the corner of 17") - or - 17"x17"x24" (which has a depth from the face to the corner of 12"), respectively. (if this is a bit confusing the way i wrote it, i can try to post some drawings of my ideas)

Which would be more effective? Creating deeper superchunks to fill the corners, or having twice as much corner coverage (or more money to spend treating other areas of the room)?

I do want to add more (non-corner based) bass traps - probably 4" thick 703 panels - as funds permit.

Also, besides this treatment, I have two framed 2'x4'x5" panels consisting of a two 1" 703 panel sandwiching a 3" air gap, which I plan on using at the first reflection point. Also, I have four 8'x2'x1" panels of framed 703 hinged together accordian style to act as a gobo to change the reflectiveness of areas as needed. Additionally, I plan on eventually adding a krk ergo to compensate for the problems inherent in the less than ideal (read: symmetrical) situation i currently have to work with (living in an apartment, unable to create permanent installations). Any advice/criticism/etc. of my plans would be greatly appreciated.

Sorry for the lengthy post - I just wanted to be clear!

Thanks in advance for your help and time!

-Mike

Last edited:

)

)

Now, if you were placeing the panels DIAGONALLY across the corner...well, thats an entirely different animal.

Now, if you were placeing the panels DIAGONALLY across the corner...well, thats an entirely different animal.

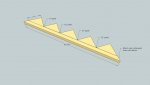

Considering it takes (6) 2'x4' panels of 4" thick 703, to make 1 corner superchunk vs doing this....

Considering it takes (6) 2'x4' panels of 4" thick 703, to make 1 corner superchunk vs doing this....

That is unless you can afford that little bit of extra absorption and the new toy.

That is unless you can afford that little bit of extra absorption and the new toy.

Welcome to the bbs mhch. Always nice to see a different/better way to do things.

Welcome to the bbs mhch. Always nice to see a different/better way to do things.