Dan Merrill

New member

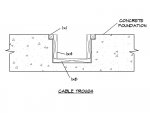

I've got three rooms to connect with snake cabling: the control room, iso booth, and amp room. Basically, I'll have three multipair cables coming to the mixer, a few Cat5 cables and perhaps a coax. I'm putting a hardwood floor in the control room and am wondering what solutions you guys have used for neatly getting cabling to the console. I'm planing to run at least some of this through the floated floor, but how can I get them to the mixer short of putting holes in the floor with XLR pigtails coming out? Hate to do that to the new floor. Should i use a floor box or something of the like?

Anyone have some pics of what they've done?

Also, I think I've anticipated and over compensated for my cabling needs, but, am I a fool to not put in some sort of cable conduit while the walls and floors are open?

Anyone have some pics of what they've done?

Also, I think I've anticipated and over compensated for my cabling needs, but, am I a fool to not put in some sort of cable conduit while the walls and floors are open?