wow. done and done. I didn't know the amount of crud that built up on the shaft. There's still a bit of residue that looks like it's not coming off anytime soon, but it's definitely an improvement from how it was before being zapped with the isopropyl alcohol. It also looks like I can stand to take some photography lessons from you since my distance always fails to capture the microscopic particles left on the parts--such as the capstan shaft.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

sound dropouts with Teac A-2300SR

- Thread starter Sonarcade

- Start date

Vintage Texas

New member

That's great, so shaft is all clean ?

Vintage Texas

New member

Now turn the deck around again and slide the drive-belt off the fly-wheel.

There is a steel-ball in the center of the fly-wheel assembly, don't loose it.

Sometimes it drops down on the pc-board below so keep an eye open while

you now carefully slide the fly-wheel out.

Press from the front on the capstan shaft while you pull out from the back.

Sometimes if there is crud left this can be complicated as it's a tight fit thru the bushing inside.

If it get stuck push it back a little and turn the fly-wheel a couple of times and try again until it's completly out.

Now you can see this:

There is a steel-ball in the center of the fly-wheel assembly, don't loose it.

Sometimes it drops down on the pc-board below so keep an eye open while

you now carefully slide the fly-wheel out.

Press from the front on the capstan shaft while you pull out from the back.

Sometimes if there is crud left this can be complicated as it's a tight fit thru the bushing inside.

If it get stuck push it back a little and turn the fly-wheel a couple of times and try again until it's completly out.

Now you can see this:

Vintage Texas

New member

Looks great, you did good !

Vintage Texas

New member

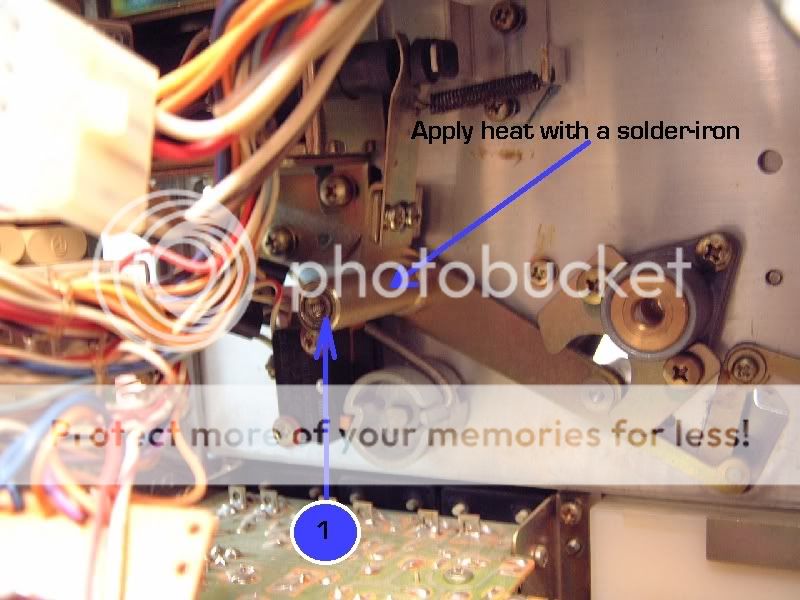

Look inside to the left and where the phillips screw was attached is a sleeve that control linkage for the pinch-roller movement. # 1

This is the one that's stuck on yours.

So use the solder-iron on the outer section of the sleeve and heat it up for 4-5 minutes.

Be careful not melt any wires going to the switches on the left side.

After a good warm-up, move the pinch-roller arm from the front up and down

a couple of times, then use the oil on where the phillips screw was attached.

A couple of drops and lean the deck forward 3-4 inches so the oil sips in between the outer and inner sleeve.

This is the one that's stuck on yours.

So use the solder-iron on the outer section of the sleeve and heat it up for 4-5 minutes.

Be careful not melt any wires going to the switches on the left side.

After a good warm-up, move the pinch-roller arm from the front up and down

a couple of times, then use the oil on where the phillips screw was attached.

A couple of drops and lean the deck forward 3-4 inches so the oil sips in between the outer and inner sleeve.

Last edited:

Vintage Texas

New member

The pinch-roller arm should drop down directly without any hesitation.

Sometimes the heating process has to be done 2 times before the old gummed up grease inside loosen up.

The new oil will sip in between and make it like new again

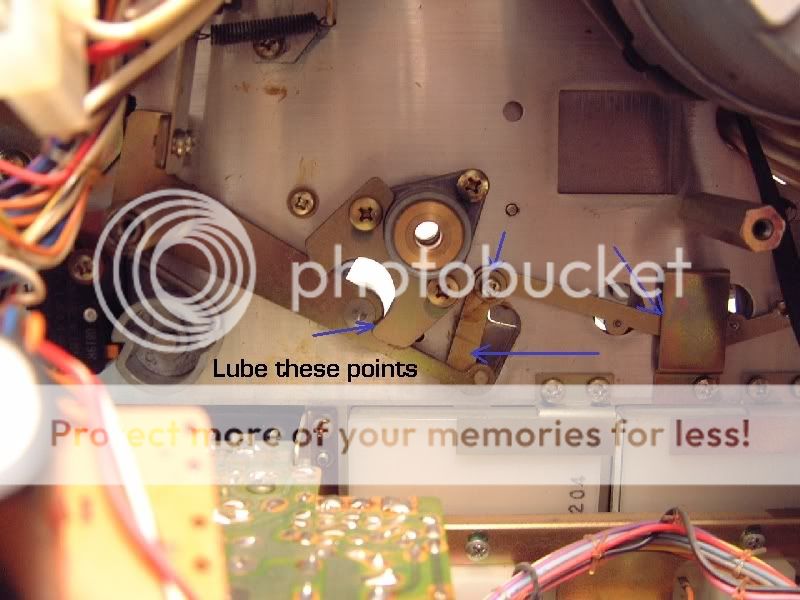

After you done with the sleeve, put a couple of oil on these spots marked out.

You can wipe the old yellow grease off with a Q-tip and alcohol first before oiling the pivot-points:

Sometimes the heating process has to be done 2 times before the old gummed up grease inside loosen up.

The new oil will sip in between and make it like new again

After you done with the sleeve, put a couple of oil on these spots marked out.

You can wipe the old yellow grease off with a Q-tip and alcohol first before oiling the pivot-points:

Vintage Texas

New member

After you oiled the linkage, it's a good time to oil the two motor bearings.

Each has a filler tube on top, put 3 drops in each one.

The rear tube is little tricky to reach so I use a extension on my Gun-Oil "handy package"

After that, check the linkage again before assembly.

Any questions ?

Each has a filler tube on top, put 3 drops in each one.

The rear tube is little tricky to reach so I use a extension on my Gun-Oil "handy package"

After that, check the linkage again before assembly.

Any questions ?

Vintage Texas

New member

Here is the parts on the fly-wheel shaft when you put it back together again.

just wanted to check in with you. when taking the capstan belt out, I didn't feel or hear a steel ball drop. I hope this doesn't mean that it's already been dropped after being jostled around in the car. I also think I may have gone overboard on the oil since I see it trickling along the front dress plate. Incidentally, it trickled its way to a couple of the lube points I was supposed to get to eventually =). I'm not too sure how strong the iron's supposed to be considering my little heat pencil barely leaves the screw sleeve a little above warm. At any rate, the pinch roller arm has started to descend -- though it seems to struggle on its way down like it's covered with molasses (or the gunk you mentioned earlier). I fidgeted with the arm up and down a bit to get the oil going and to catalyze the "sipping" process but I'm guessing it comes down to a little timing and art when handling this stuff.

Hopefully I haven't gone too stray from the path you've mapped out for me. If so, I swear, it wasn't intentional but simply out of misunderstanding. Thanks for bearing with me so far.

Hopefully I haven't gone too stray from the path you've mapped out for me. If so, I swear, it wasn't intentional but simply out of misunderstanding. Thanks for bearing with me so far.

Vintage Texas

New member

You doing OK, just heat up the sleeve more and add a few drops of oil around.

Vintage Texas

New member

Just checking if you having problems

looking at just how much time has elapsed within our back and forth alone, I couldn't believe just how much time was spent on heating and oiling the darn thing. It was stubborn. Everything else was a breeze, thanks to your thorough directions. I also vowed from now on to arrange my parts in order like the way you have your capstan parts laid out. By the end of the night, I was about to pull out the WD-40, but konked out. Next day, the reel to reel fairy came and resolved everything. Perhaps the oil needed to sit in the sleeve a bit? Also, I have a feeling the weight of the pinch roller may have triggered the mechanism or something. I don't know. I was feeling the spring attached inside needed some replacing. But in the end, it worked, it worked, it worked.

Then came the recording and somehow the "shakes" are still in the sound for some reason. I think now it comes down to the way I threaded the tape and the way it's twisting. The reason why the Tascam 38 doesn't exhibit this problem is probably due to the width of the tape, but that's at best a guess. For our records and posterity, I have these pics.

and yes, this rig has definitely seen better days. Check out the grease on the front dress plate. blech!

Then came the recording and somehow the "shakes" are still in the sound for some reason. I think now it comes down to the way I threaded the tape and the way it's twisting. The reason why the Tascam 38 doesn't exhibit this problem is probably due to the width of the tape, but that's at best a guess. For our records and posterity, I have these pics.

and yes, this rig has definitely seen better days. Check out the grease on the front dress plate. blech!

Vintage Texas

New member

You are right, it can be stubborn sometimes, I sometime leave it tilted overnight so oil reach in all around inside.

Great you got that part done.

Thanks for the pictures, but the tape is not threaded right.

The guide after the pinch-roller, tape should be on top instead.

I also see a really dirty tape-guide on the right side of the headstack.

Here is the way the tape should be:

Left side:

Also give that pinch-roller a good cleaning with some Windex but be sure to wipe it dry afterwards.

You have a good model and if the heads are OK, some elbow grease and one evening you get it going again.

I finished my deck here last night, here is a video:

http://s128.photobucket.com/albums/p183/Texas59/?action=view¤t=Default_6.flv

Great you got that part done.

Thanks for the pictures, but the tape is not threaded right.

The guide after the pinch-roller, tape should be on top instead.

I also see a really dirty tape-guide on the right side of the headstack.

Here is the way the tape should be:

Left side:

Also give that pinch-roller a good cleaning with some Windex but be sure to wipe it dry afterwards.

You have a good model and if the heads are OK, some elbow grease and one evening you get it going again.

I finished my deck here last night, here is a video:

http://s128.photobucket.com/albums/p183/Texas59/?action=view¤t=Default_6.flv

Vintage Texas

New member

It was made 1972 Song John, and yes, little more complicated then nowdays recording devices, but sweet pure sound

I apologize again for the delay. So I ran a few tests with the proper and improper threading technique and the shakes have reduced quite drastically! I may add to this as time goes on but for now, I think you pretty much fixed the problem, Rolf! Thanks a million, once more.

One might say that the previous owner's abuse of the machine is something of a blessing in disguise, seeing as how this may prep me for repairing my Tascam 38, if need be. It's kind of surprising just how easily maintainable these machines are and how you don't need a microscope and tweezers to get things going again.

Anyway, this machine has been owned by a smoker and perhaps that may explain the stains on the dress panel. But the other non-cosmetic flaw is that the inner and outer knobs (line, mic, and output as shown in your picture Rolf) can't move independently of one another unless I use both hands to either hold one or move both in opposite directions. I imagine the solution to this will be much easier than the oiling business. I'm kind of glad that my dinky 23w soldering pencil could adequately do the job. I was afraid that I'd have to replace it.

I may have to buy another take-up reel though because the tape still twists along the inner side of it, despite all attempts at adjusting the screw on the nabs that allow for moving the reel table heights.

songjohn- yeah, VintageTexas' video and pictures show how my machine could look like. The grain of the metal is just stunning!

One might say that the previous owner's abuse of the machine is something of a blessing in disguise, seeing as how this may prep me for repairing my Tascam 38, if need be. It's kind of surprising just how easily maintainable these machines are and how you don't need a microscope and tweezers to get things going again.

Anyway, this machine has been owned by a smoker and perhaps that may explain the stains on the dress panel. But the other non-cosmetic flaw is that the inner and outer knobs (line, mic, and output as shown in your picture Rolf) can't move independently of one another unless I use both hands to either hold one or move both in opposite directions. I imagine the solution to this will be much easier than the oiling business. I'm kind of glad that my dinky 23w soldering pencil could adequately do the job. I was afraid that I'd have to replace it.

I may have to buy another take-up reel though because the tape still twists along the inner side of it, despite all attempts at adjusting the screw on the nabs that allow for moving the reel table heights.

songjohn- yeah, VintageTexas' video and pictures show how my machine could look like. The grain of the metal is just stunning!

Vintage Texas

New member

No problem with the delay, I had a feeling you were tinkering

Glad the tape run smoother and sound improved now.

I noticed the faceplate, but you can clean that off, some elbow grease and pleasant music at the same time, it wil shine like the pearly gates

About the three dual knobs, they are made like that, only when you use two fingers you able to change from L + R.

Im sure after you start using this Teac you be tempted fixing the 38, but little more sensitive compare to 2300 model.

Is the take-up reel plastic or metal ?

Glad the tape run smoother and sound improved now.

I noticed the faceplate, but you can clean that off, some elbow grease and pleasant music at the same time, it wil shine like the pearly gates

About the three dual knobs, they are made like that, only when you use two fingers you able to change from L + R.

Im sure after you start using this Teac you be tempted fixing the 38, but little more sensitive compare to 2300 model.

Is the take-up reel plastic or metal ?

Vintage Texas

New member

So maybe the plastic flange is bent on your take up reel ?

Try some Windex with Lime action for the nicotine, comes off really good

Try some Windex with Lime action for the nicotine, comes off really good