technoplayer

Recovering Gear-aholic

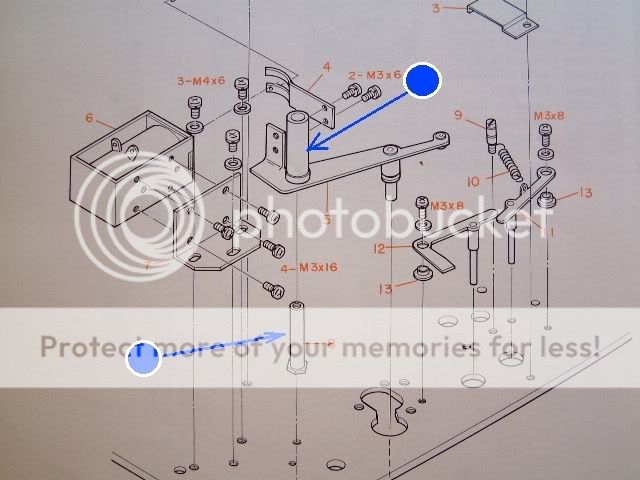

I was doing a re-start on my dormant Teac 2340R and all is well except the solenoid that pulls in the pinch roller seems wimpy. What i mean is usually the solenoiid on these pull in with a sharp click; now it comes in a bit slower.

I lubed the pivot points and cleaned the solenoid barrel, and it makes no real difference.The solenoid does not engage fast enough, the reel moters somtimes pull the tape at a higher speed unitl the pinch roller makes contact. It is much more pronounced in two channel mode when kicking into reverse play. The solenoids that release the reel brakes click off, but the pinch roller solenoid never "clicks" in, but kind of slowly mushes in.

i am looking for learned opinions: Is this symptomatic of

1) Bad or weak solenoid

2) Bad or weak component like a capactor in that circuit ( no I do NOT have a schematic) that might not be passing full voltage

3) Possible bad "other" circuitry.

The machine is pristine and everything else functions perfect.

?????

I lubed the pivot points and cleaned the solenoid barrel, and it makes no real difference.The solenoid does not engage fast enough, the reel moters somtimes pull the tape at a higher speed unitl the pinch roller makes contact. It is much more pronounced in two channel mode when kicking into reverse play. The solenoids that release the reel brakes click off, but the pinch roller solenoid never "clicks" in, but kind of slowly mushes in.

i am looking for learned opinions: Is this symptomatic of

1) Bad or weak solenoid

2) Bad or weak component like a capactor in that circuit ( no I do NOT have a schematic) that might not be passing full voltage

3) Possible bad "other" circuitry.

The machine is pristine and everything else functions perfect.

?????