You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

how do you make a fabric wall?

- Thread starter djgc

- Start date

I went to few studios and they all have some sort of fabric wall and when i tried poking it inside is kind of hollow and soft.

I was wondering how do you build such a wall?

are you referring to an open stud construction wall?

which correct me if i'm wrong. is a non dry wall wall covered in fabric and packed with thick insulation between the studs. just the fabric over the studs which makes the entire wall a large sound panel .

a non dry wall wall

Let's see... "non dry-" so, it's WET?

"wall wall-" does that mean it's TWO walls, or does being a "wall wall" cancel each other out?

So, either a wet double wall, or a wet non-wall?

Boy, am I confused!

M

Mike Keith

Guest

You can do this a couple of different ways..

One is the most $$$, a specifically designed assembly made from vinyl.

Another way is the way I have done it many times; using a 2 by 4 on its edge for the main frame, like a large picture frame, install a material made for screens on a porch, use the same fabric most use Gilford of Maine..

Looks great and is less $$ than option one..

My web site shows rooms that have this method..can have it from floor to ceiling or what ever..

I have used 2 by 6 for thicker panels..

Here's a pic of a few I built.

The drum booth goes from floor to ceiling and is built from 2 by 6, you can NOT tell how thick they are, can't see much from these pics..

They contain your basic 703..

One is the most $$$, a specifically designed assembly made from vinyl.

Another way is the way I have done it many times; using a 2 by 4 on its edge for the main frame, like a large picture frame, install a material made for screens on a porch, use the same fabric most use Gilford of Maine..

Looks great and is less $$ than option one..

My web site shows rooms that have this method..can have it from floor to ceiling or what ever..

I have used 2 by 6 for thicker panels..

Here's a pic of a few I built.

The drum booth goes from floor to ceiling and is built from 2 by 6, you can NOT tell how thick they are, can't see much from these pics..

They contain your basic 703..

Attachments

Weasel9992

New member

Hey Mike! Welcome to the forums. Do what Mike says...he knows what he's doing.

fraserhutch

Flypaper for freaks

And behind those 'panels' is the insulation? The idea is not to have reflective surface for walls?

Would you do this for all walls in a room? Or just two? One? What criteria for determining which?

Would you do this for all walls in a room? Or just two? One? What criteria for determining which?

You can do this a couple of different ways..

One is the most $$$, a specifically designed assembly made from vinyl.

Another way is the way I have done it many times; using a 2 by 4 on its edge for the main frame, like a large picture frame, install a material made for screens on a porch, use the same fabric most use Gilford of Maine..

Looks great and is less $$ than option one..

My web site shows rooms that have this method..can have it from floor to ceiling or what ever..

I have used 2 by 6 for thicker panels..

Here's a pic of a few I built.

The drum booth goes from floor to ceiling and is built from 2 by 6, you can NOT tell how thick they are, can't see much from these pics..

They contain your basic 703..

M

Mike Keith

Guest

Depends on the room and use..

Last edited:

RICK FITZPATRICK

New member

There are lots of ways of covering a wall of aborption with fabric. The way most pro studio designers spec it is with FabricTrak systems. Here are some of the profiles and a few examples. Unfortunately, most firms that sell this stuff, sell it as a system, which means you must hire an "installation"company to get it. But there are a few which sell the track direct. You just have to do a search on "fabric track".

Attachments

producerkeith1

New member

Mike, I'm trying to understand the exact means for which I can build the fabric wall, not the frame. I'm treating my vocal booth and I'm going to have to build a wall. So, before I go and sheet rock the room, I want to consider this type of wall covering. I have tons of 703 fiberglass and mineral wool. I just need to know how to cover the walls without the seams showing, etc.

Any help or links I should check out?

Any help or links I should check out?

You can do this a couple of different ways..

One is the most $$$, a specifically designed assembly made from vinyl.

Another way is the way I have done it many times; using a 2 by 4 on its edge for the main frame, like a large picture frame, install a material made for screens on a porch, use the same fabric most use Gilford of Maine..

Looks great and is less $$ than option one..

My web site shows rooms that have this method..can have it from floor to ceiling or what ever..

I have used 2 by 6 for thicker panels..

Here's a pic of a few I built.

The drum booth goes from floor to ceiling and is built from 2 by 6, you can NOT tell how thick they are, can't see much from these pics..

They contain your basic 703..

RecordingMaster

A Sarcastic Statement

What I always wondered is if all four walls were covered from floor to ceiling with OC, wouldn't that over-deaden the room similar to covering it with foam? I know foam mostly only deadens the higher frequencies and leaves the lows, but if you had OC it really only just absorbs a broader band of frequencies. So unless you're going to go and put up some diffusion on the ceiling and/or hanging diffusers on the "fabric walls" in strategic spots, wouldn't covering all your walls from floor to ceiling, even with OC, without leaving some un-treated wall space, render the room overly-dead and dry with no sense of air, openness or diffusion?

Mike, I'm trying to understand the exact means for which I can build the fabric wall, not the frame.

Well, I'm not Mike, but here is an answer. It's called an INSIDE OUT WALL. However, this has to do with how your studio is constructed in the first place. The reason is to keep any TWO LEAF systems intact.

Here's the deal. USUALLY, these type walls are only part of a DOUBLE WALL system, where one of the double walls has ONE leaf of drywall fastened to the room side of the studs, and the Inside Out wall, has the drywall fastened to the airgap side of the studs. This keeps the two leaf system intact while allowing the use of the stud cavitys to be filled with absorption materials, while providing the stud edge for a place to staple fabric. Most Pro studios have EITHER, an Inside out wall somewhere, or enough space to build standard double walls, with fixtures designed to hold absorption material in substantial depths for bass traps, and reflective/diffusive elements as well.

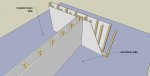

Here is a standard Double wall...

Here is a Double Wall with one leaf built as an "inside out" wall.

The problem with building an inside out wall in a Home studio, is keeping a two leaf system intact. If you are adding a partition wall within a room, then it has to be a double wall with one inside out leaf. If you simply add an inside out wall parallel and adjacent to an existing partition wall, the existing partition wall is most likely already a two leaf system...that is...drywall on both sides of a wood frame. (SEE NEXT POST) To make the inside out wall maintain the two leaf system, you would have to REMOVE the drywall from the existing wall(on the side facing the new inside out wall, and then erect your new inside out wall, which btw, is NOT an easy task,(and dumb in the first place unless you want double walls) as usually, you have to build a precision wall on the floor, sheath it with drywall, and then lift it into place, as it is almost impossible to drywall it while IN PLACE. That's the problem with doing this in rooms that already have exisiting two leaf system assemblies .

Which essentially means...if you don't want to remove the drywall, and then build ANOTHER WALL, then you simply build a FRAME the size you want, against the existing drywall. fill it with insulation, and staple fabric over it. However, the maximum width of your fabric will tend to define where you have to provide a stapling surface. This is why MOST HR enthusiasts...simply build broadband PANELS. Besides, when you have a bunch of panels placed in a quasi checkerboard fashion or such, as a byproduct you get a modicum of diffusion as well.

HOWEVER..you said this as well.

Without seeing exactly what it is and where you are building this "wall", it's difficult to tell you how or what to do. Got a drawing of what your intentions are? That would certainly help.I'm treating my vocal booth and I'm going to have to build a wall.

Last edited:

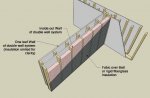

Btw, here's what I mean about building a typical wall frame OVER an existing two leaf partition wall. It does the same thing as a double wall, except that the two leafs are NOT decoupled from each other. This simply allows the existing two leaf system to be utilized, although most people contemplating doing this will ADD another layer of drywall to each side of the system to improve the Transmission loss, prior to adding a frame...which for all intents and purposes, is STILL just a frame..albeit the size of a wall. But a frame none the less.

Here's a standard two leaf partition wall.

Here it is with a framwork for holding the insulation in place.(fabric not shown)

View attachment 71721

Here's a standard two leaf partition wall.

Here it is with a framwork for holding the insulation in place.(fabric not shown)

View attachment 71721