sweetbeats

Reel deep thoughts...

technoplayer...

WAY COOL!

I'm out of town right now, but I'll check that when I'm back in town.

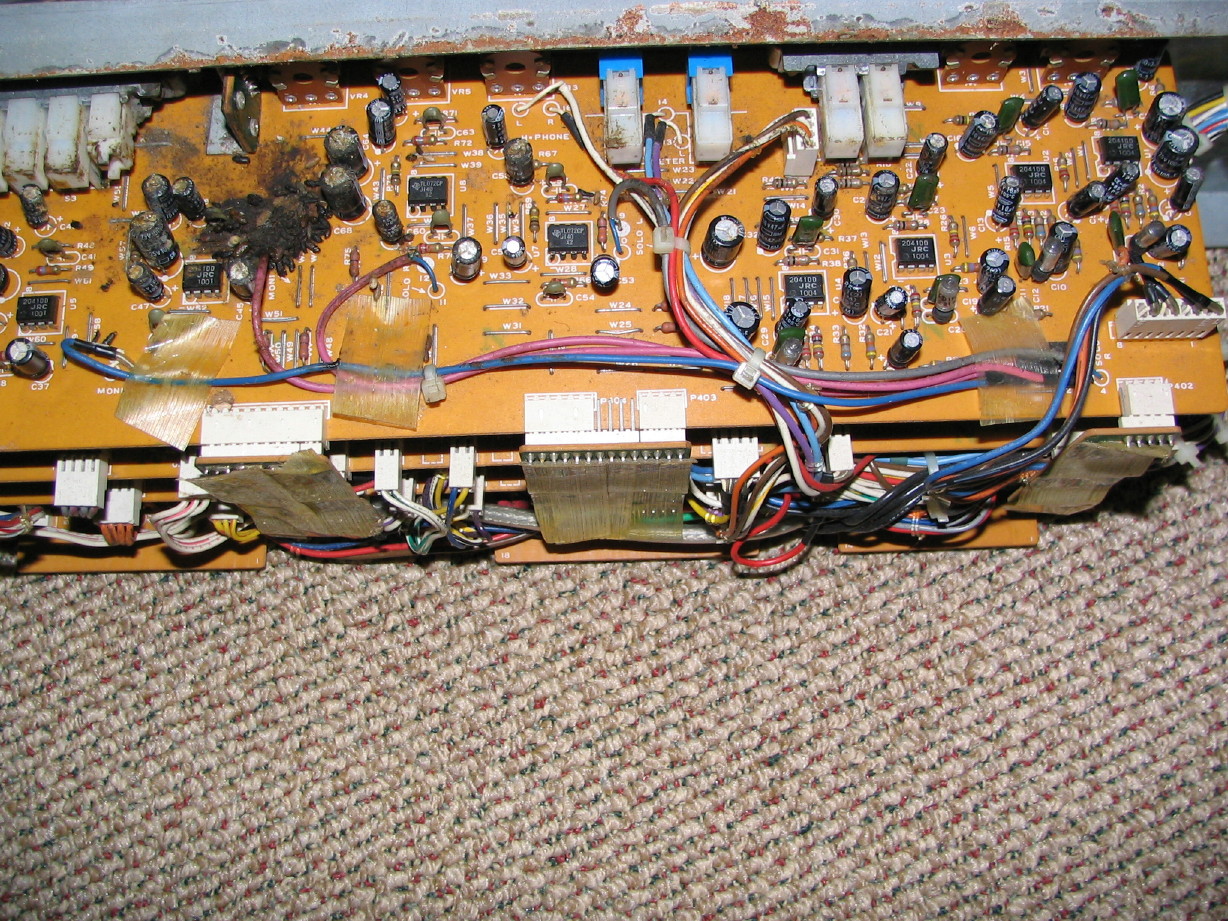

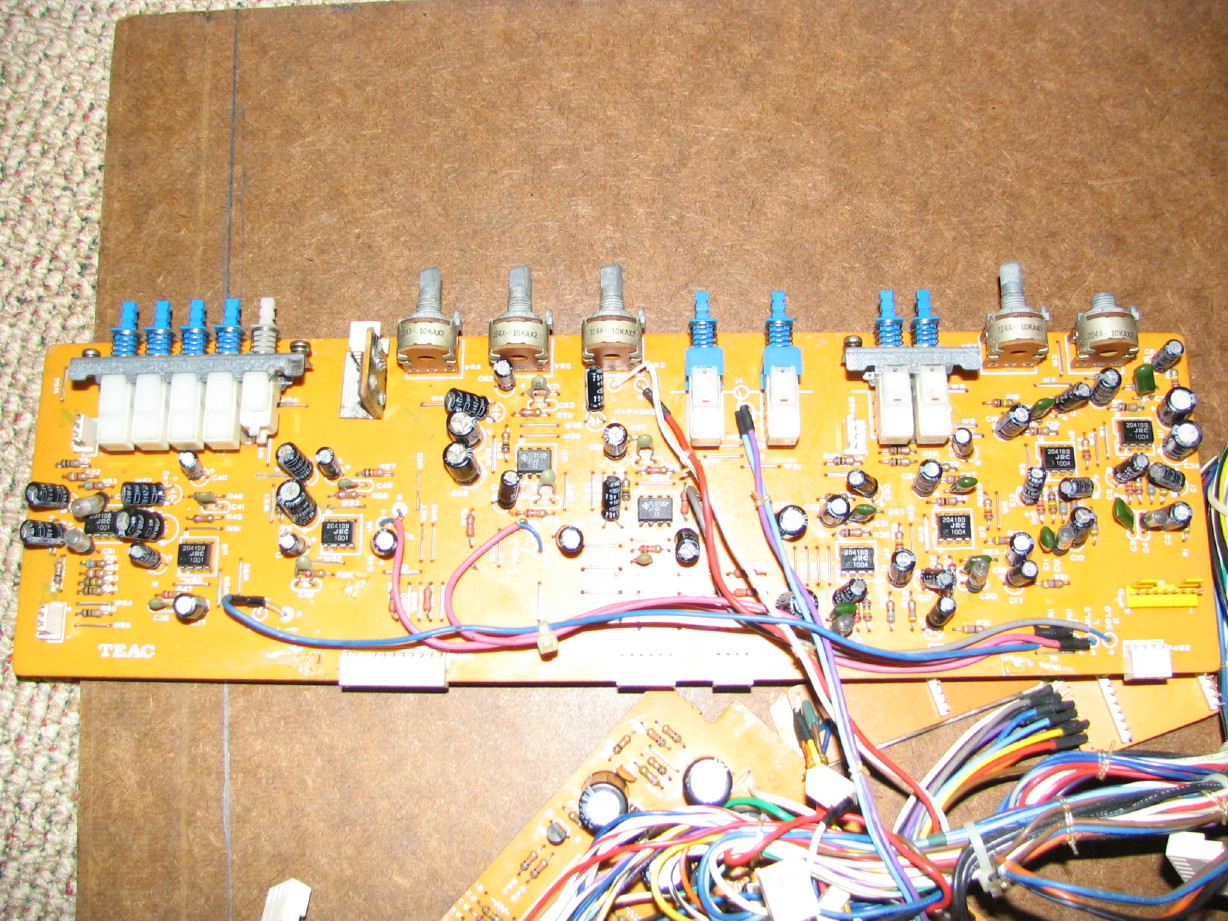

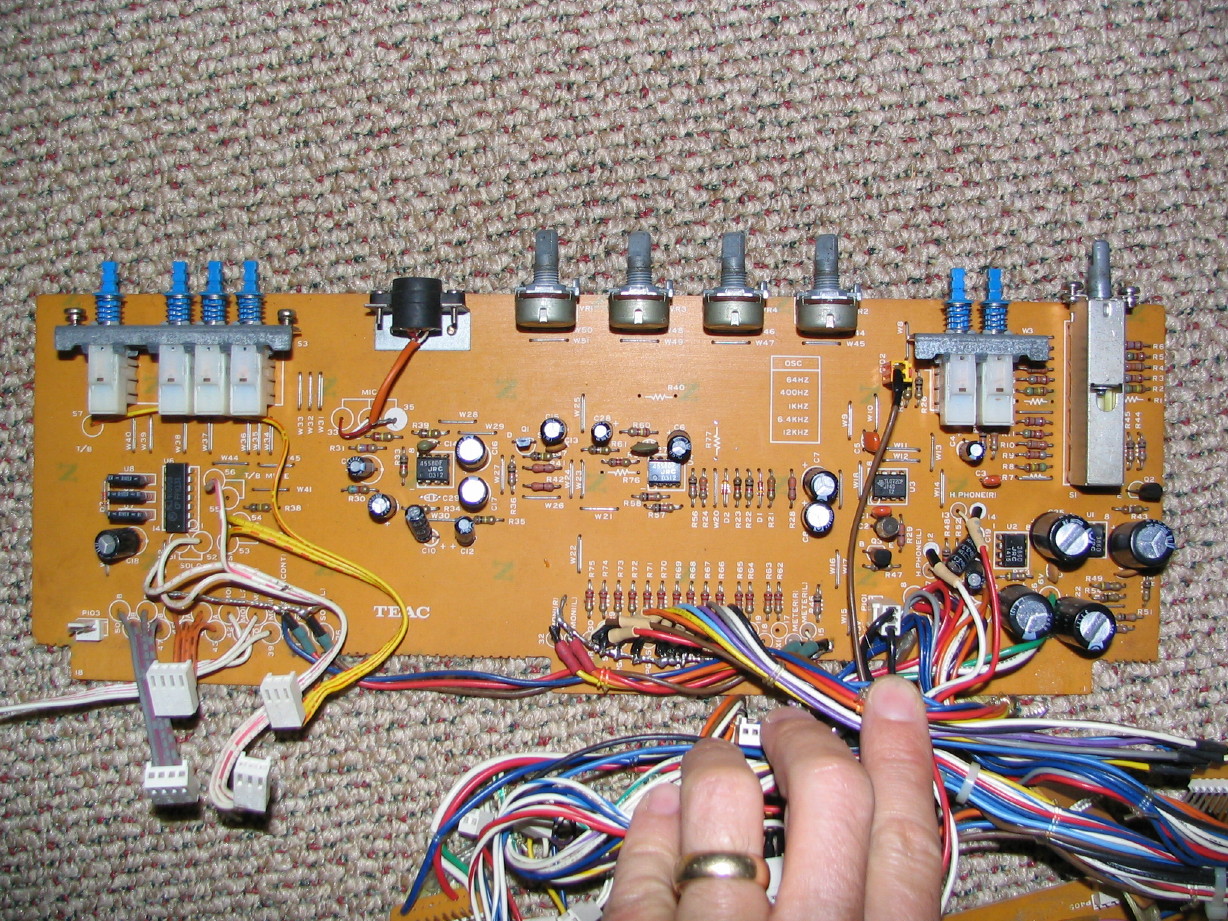

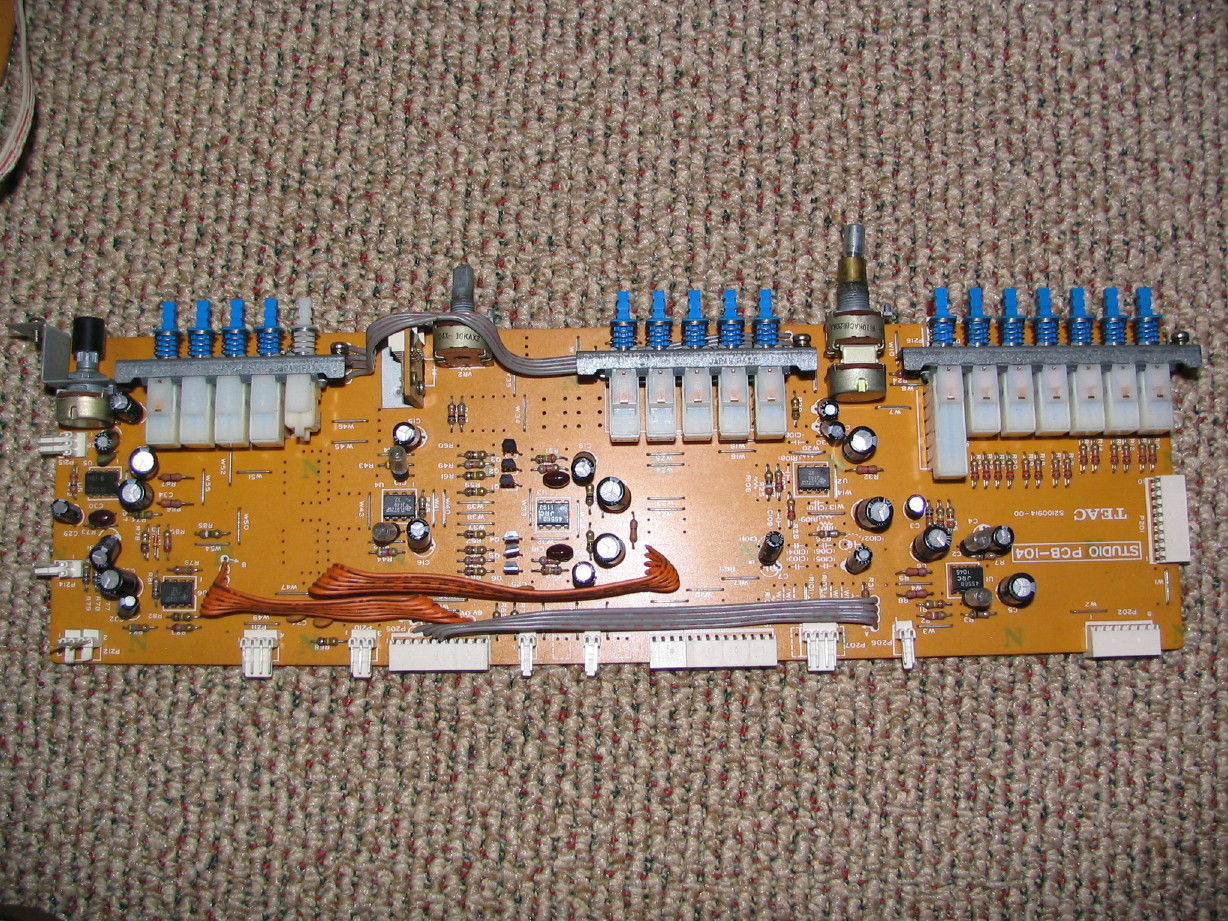

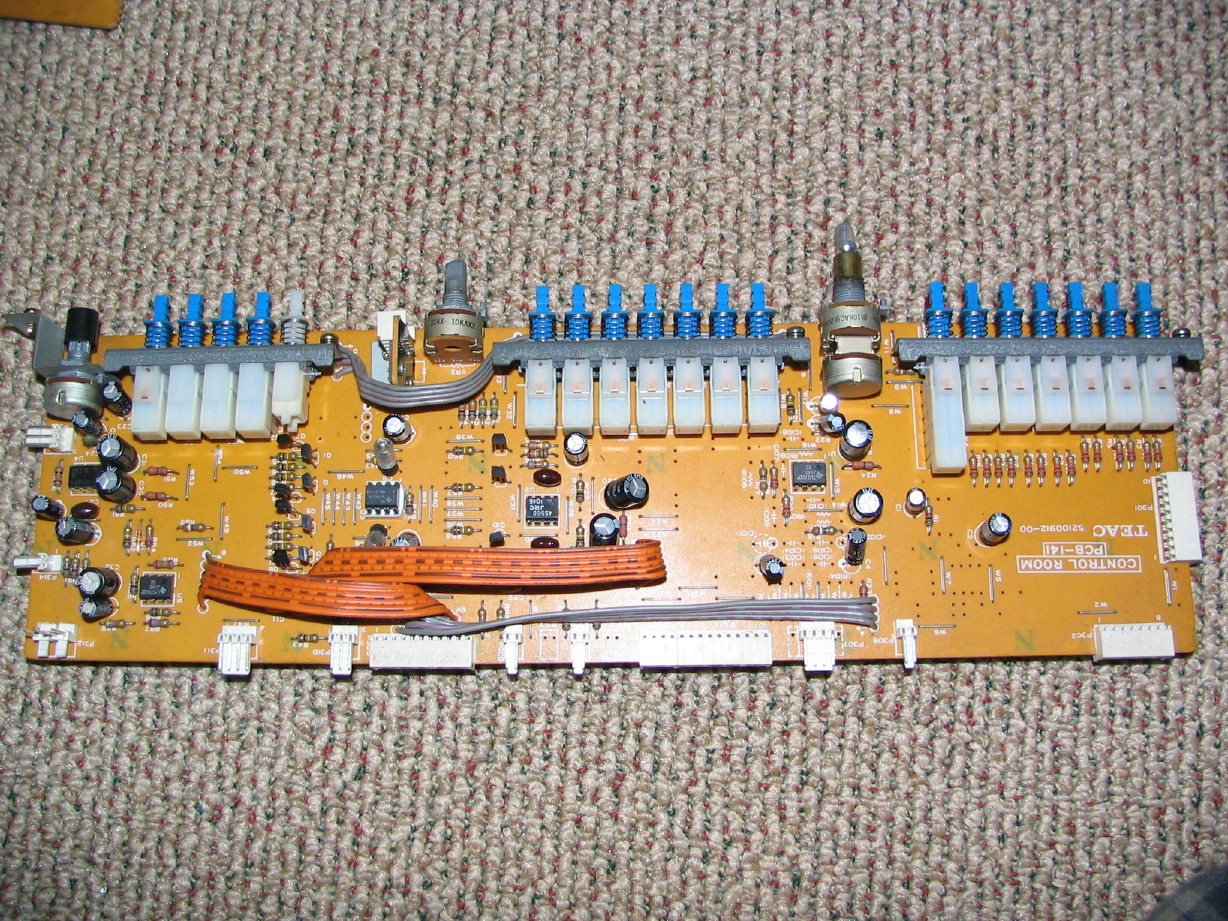

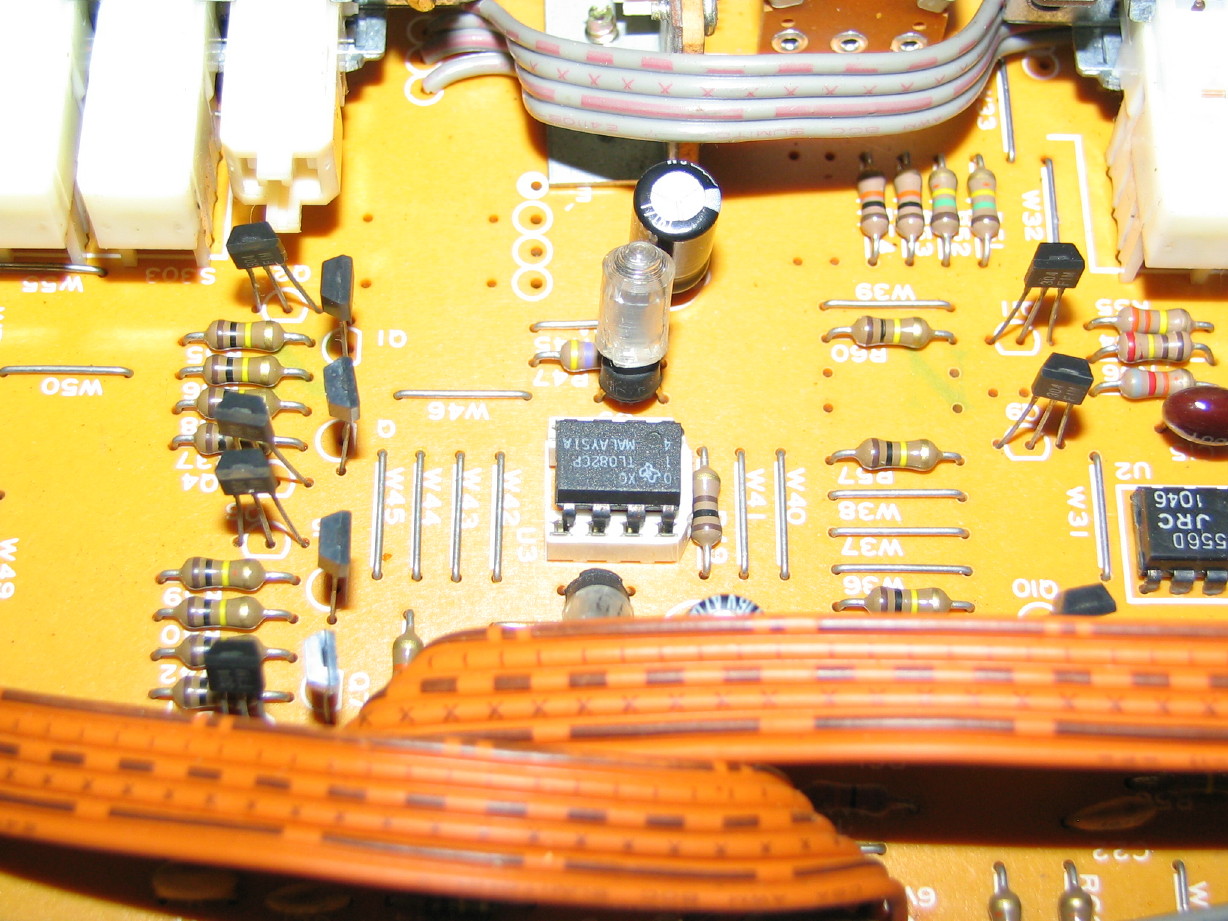

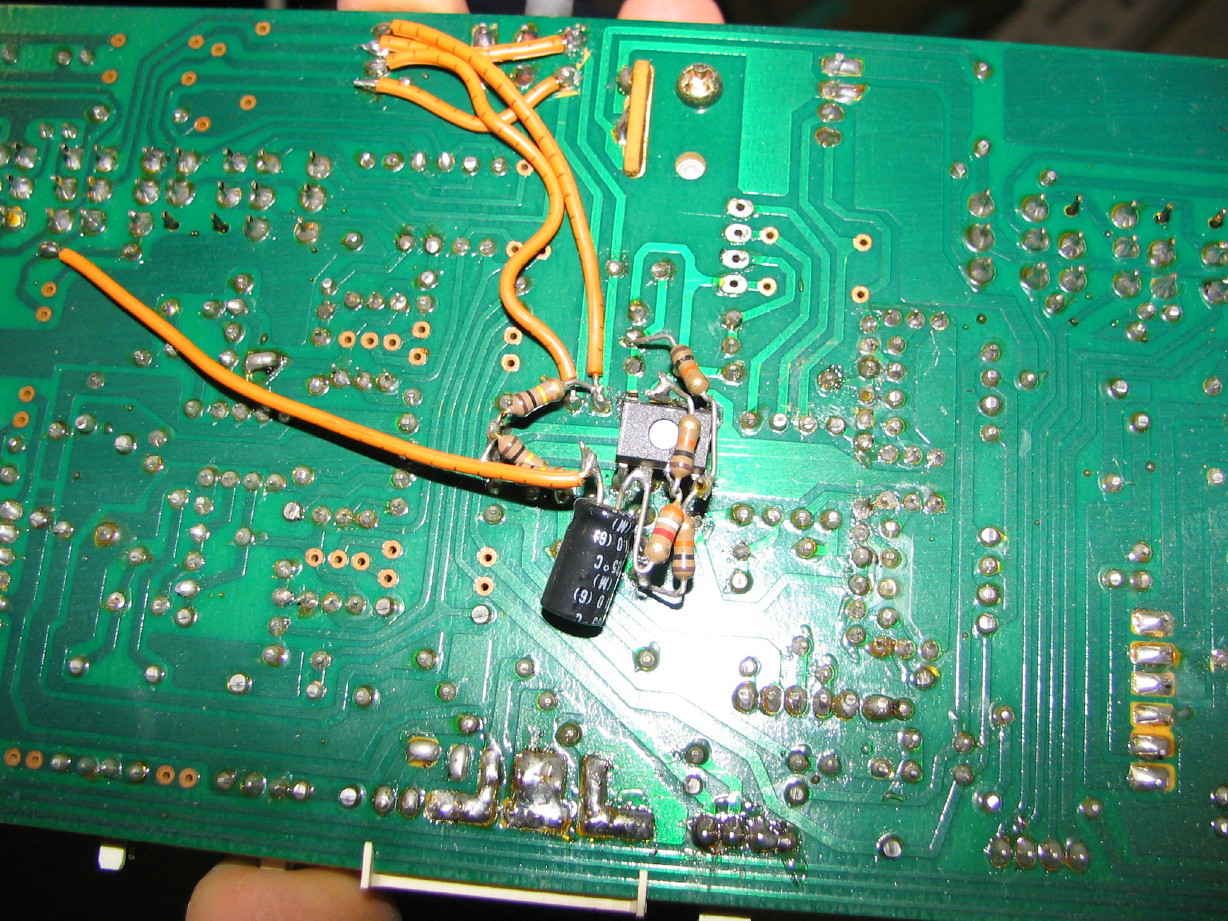

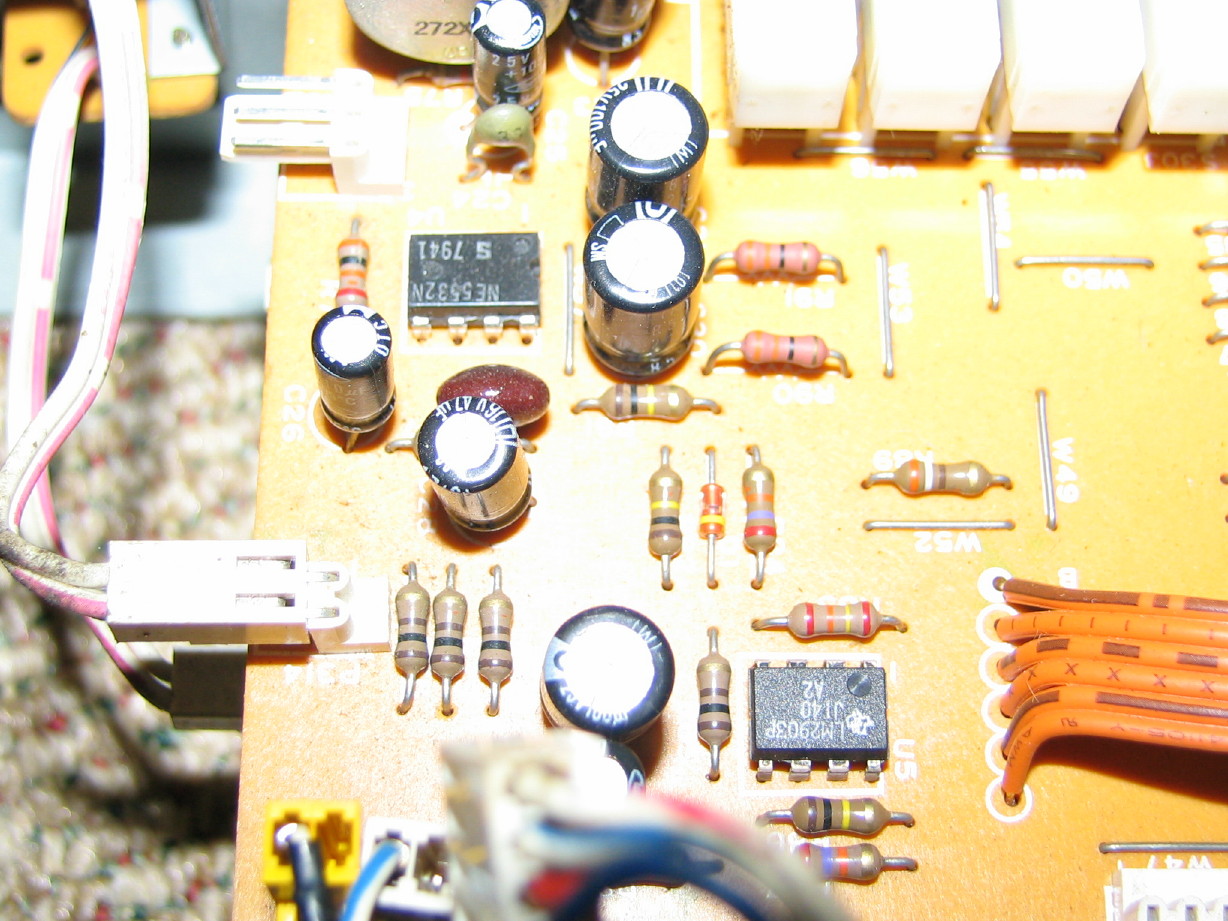

I think you're right that the chips have not been replaced. I'll look on the trace side to see if I can see any evidence of that...

You're also right that most of the 072 chips are JRC, and only one is TI. Weird...but anyway, I'll check that date reference and post it up.

Cool! Thanks!

WAY COOL!

I'm out of town right now, but I'll check that when I'm back in town.

I think you're right that the chips have not been replaced. I'll look on the trace side to see if I can see any evidence of that...

You're also right that most of the 072 chips are JRC, and only one is TI. Weird...but anyway, I'll check that date reference and post it up.

Cool! Thanks!

.JPG)

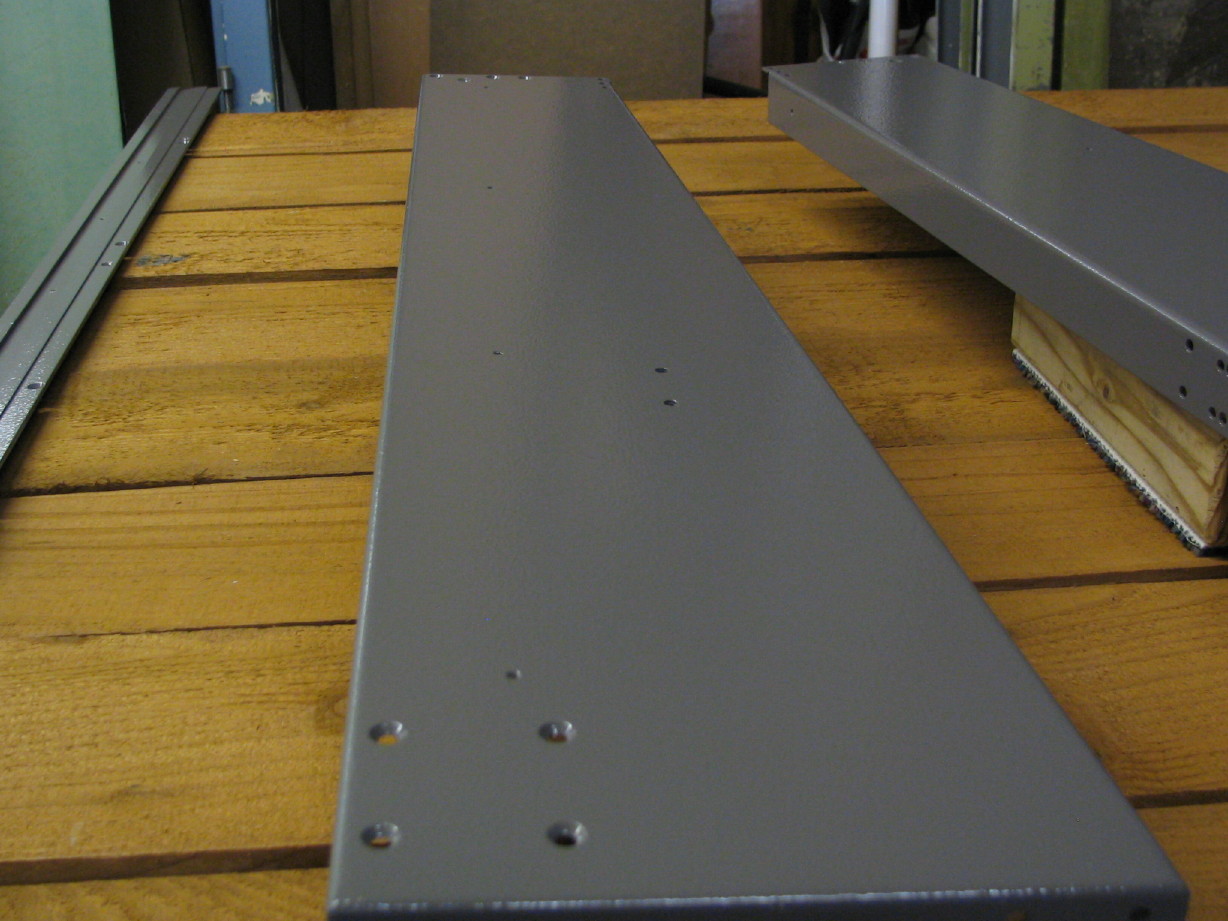

So I did the next best thing; I rolled the paint on.

So I did the next best thing; I rolled the paint on.  Honestly, it worked pretty well. I used a 4" foam roller, and because the paint is an oil-based enamel it takes a long time to dry, which is nice in this case because it levels out nice. Its actually got kind of a hammered finish but it is stock color, which is what I wanted. This paint is very durable. Its supposed to be used on, like, farm implements and stuff.

Honestly, it worked pretty well. I used a 4" foam roller, and because the paint is an oil-based enamel it takes a long time to dry, which is nice in this case because it levels out nice. Its actually got kind of a hammered finish but it is stock color, which is what I wanted. This paint is very durable. Its supposed to be used on, like, farm implements and stuff.

One of those uprights was badly pitted and thickly rusted from the mouse waste.

One of those uprights was badly pitted and thickly rusted from the mouse waste.