sweetbeats

Reel deep thoughts...

Well, as is the usual form, this "Story..." thread has its origin embedded in another thread since I still haven't figured out that every time another piece of gear follows me home, and I do a little blurb on it, it ends up endearing itself to me and there's more to the story than a blurb.

This "Story..." is a little different because I swear I wrote this up already, and some other forum members recall it too...unless they really just don't know what to do about my apparent dementia...but I can't find the thread anywhere, so you all get to enjoy this one.

So, anyway, the origins of this "Story..." starts here:

https://homerecording.com/bbs/gener...d-gear/oooooo-whats-da-box-372706/?highlight=

Shortly after picking up the 238 locally for $150 with a functional MMC-100 and associated cabling, I dove in to repair the capstan servo board. You see this 238 was going for relatively cheap because it had the dreaded "jet-engine" runaway capstan. This problem has been fairly well documented on the internet, and it seems the typical solution is a replacement of the electrolytic capacitors on the servo board (which is an integrated assembly to the capstan motor itself). The original caps are little surface mount parts. I hate surface-mount parts. There are also two film caps, but I figured those little surface-mount electrolytic caps had to be the problem...and this is partly because I already had the replacement parts on-hand which = really cheap fix, oh boy, fully-functional 238 for $150 including an antiquated piece of MMC hardware I'll never use.

surface-mount electrolytic caps had to be the problem...and this is partly because I already had the replacement parts on-hand which = really cheap fix, oh boy, fully-functional 238 for $150 including an antiquated piece of MMC hardware I'll never use.

Before I dive in to the "238 exposed" pictures I will say overall I was pleased when I met the seller to pick up the 238...all there including the sometimes missing or never mounted rack ears, a couple scuffs and scratches, but overall clean and complete, for example:

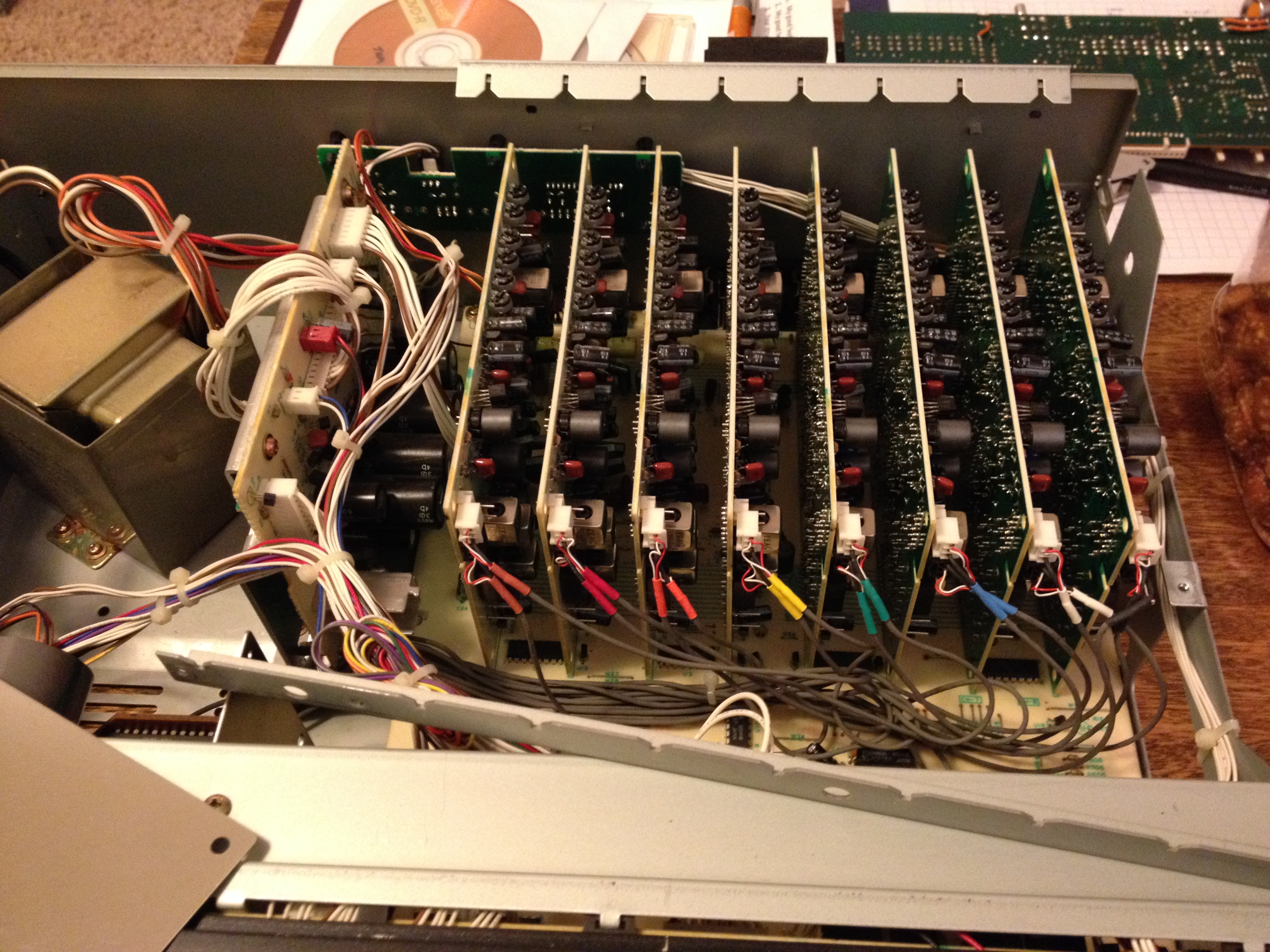

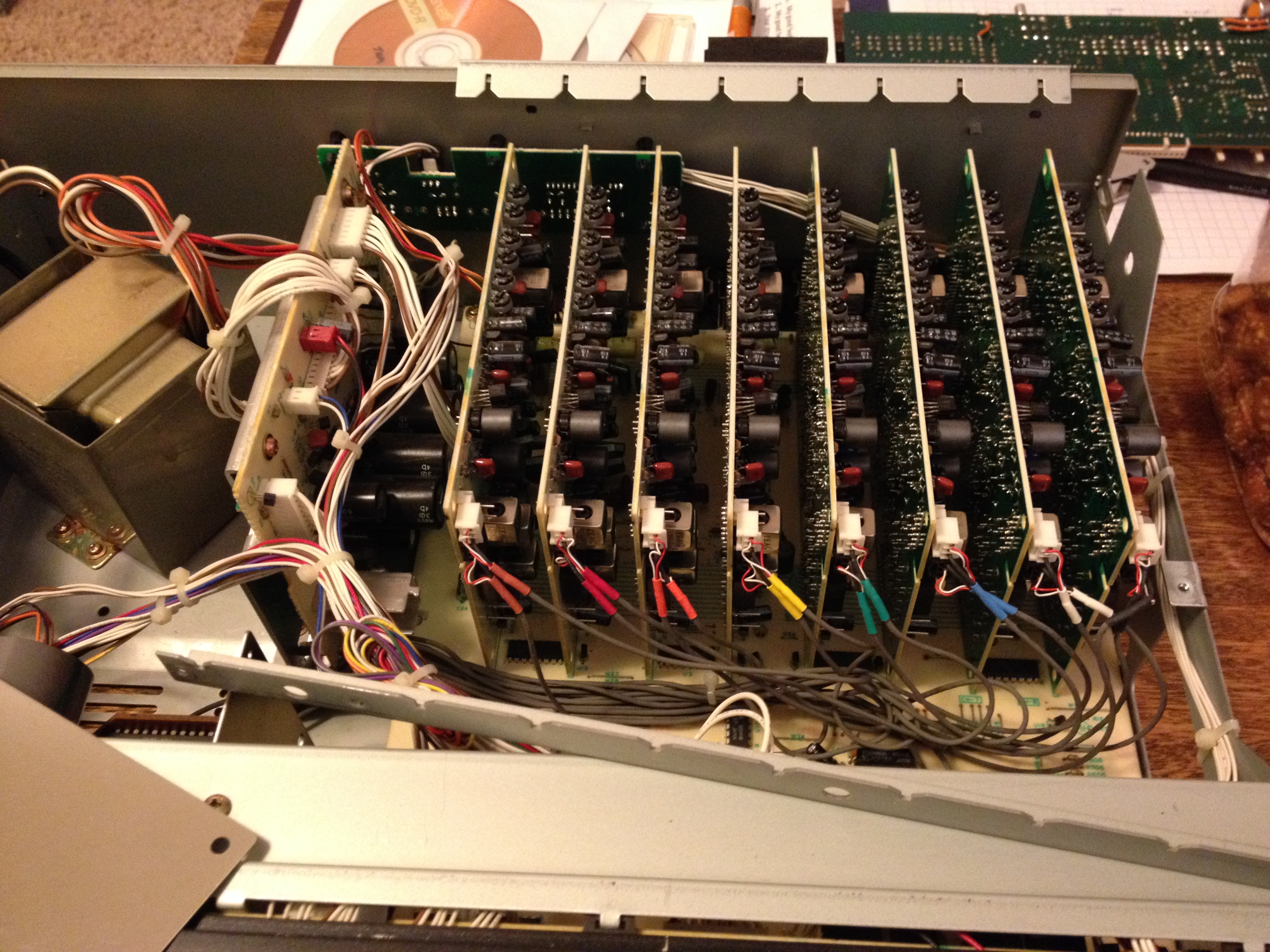

Having owned and done quite a bit of work on a 234, I was really surprised/impressed at how clean the interior of the chassis is on a 238...I mean, its really got a lot of room to work compared to the 4-track 234, and I love how the amp cards are plug-in on the 238, one card per channel with the input, output, record, and playback amps as well as the noise reduction all on the single card.

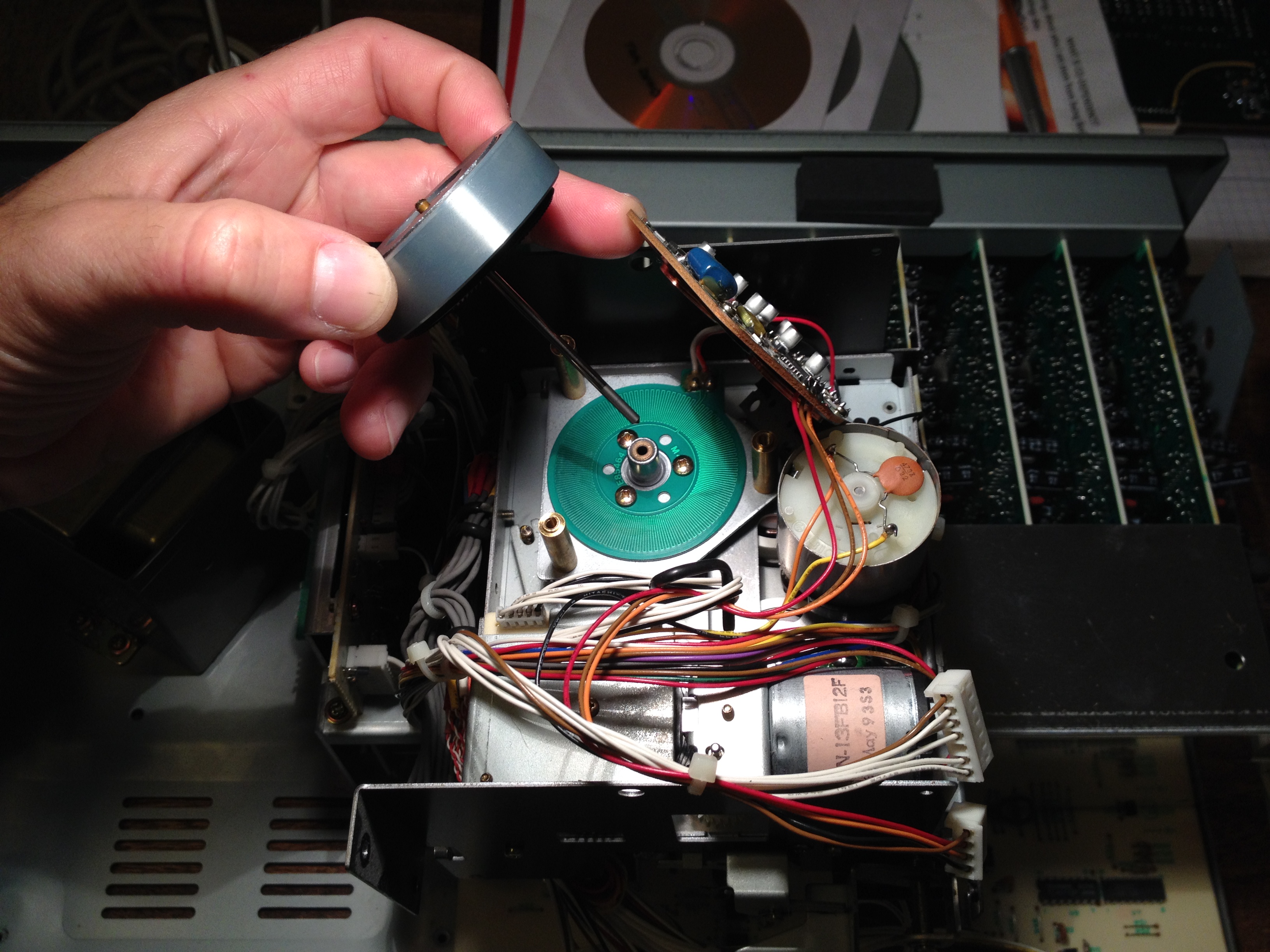

And my goodness...literally, after removing a structural cross-member, remove two screws, remove the cassette bay door, and the entire transport assembly is ready to unplug (a few connectors) and remove:

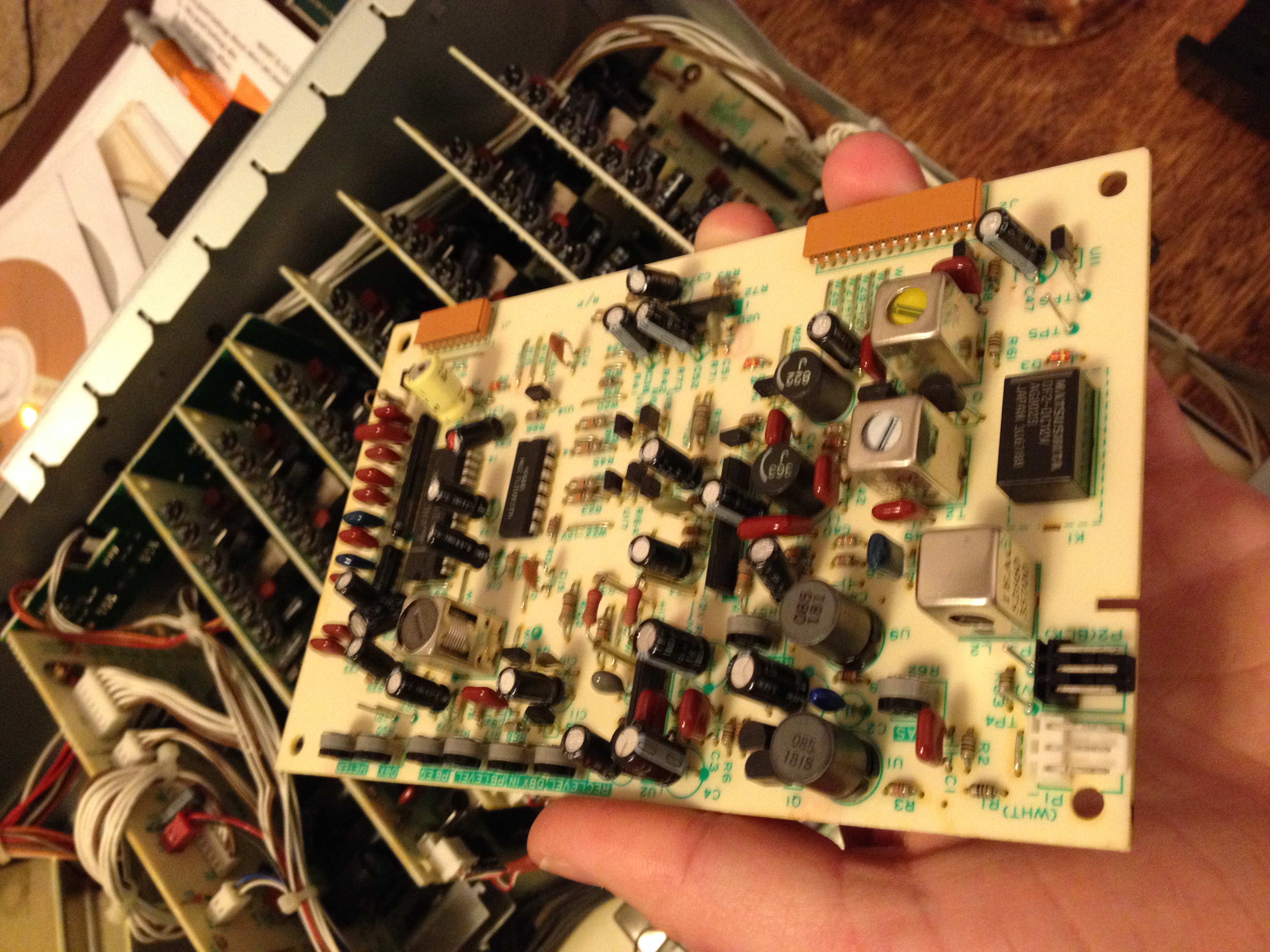

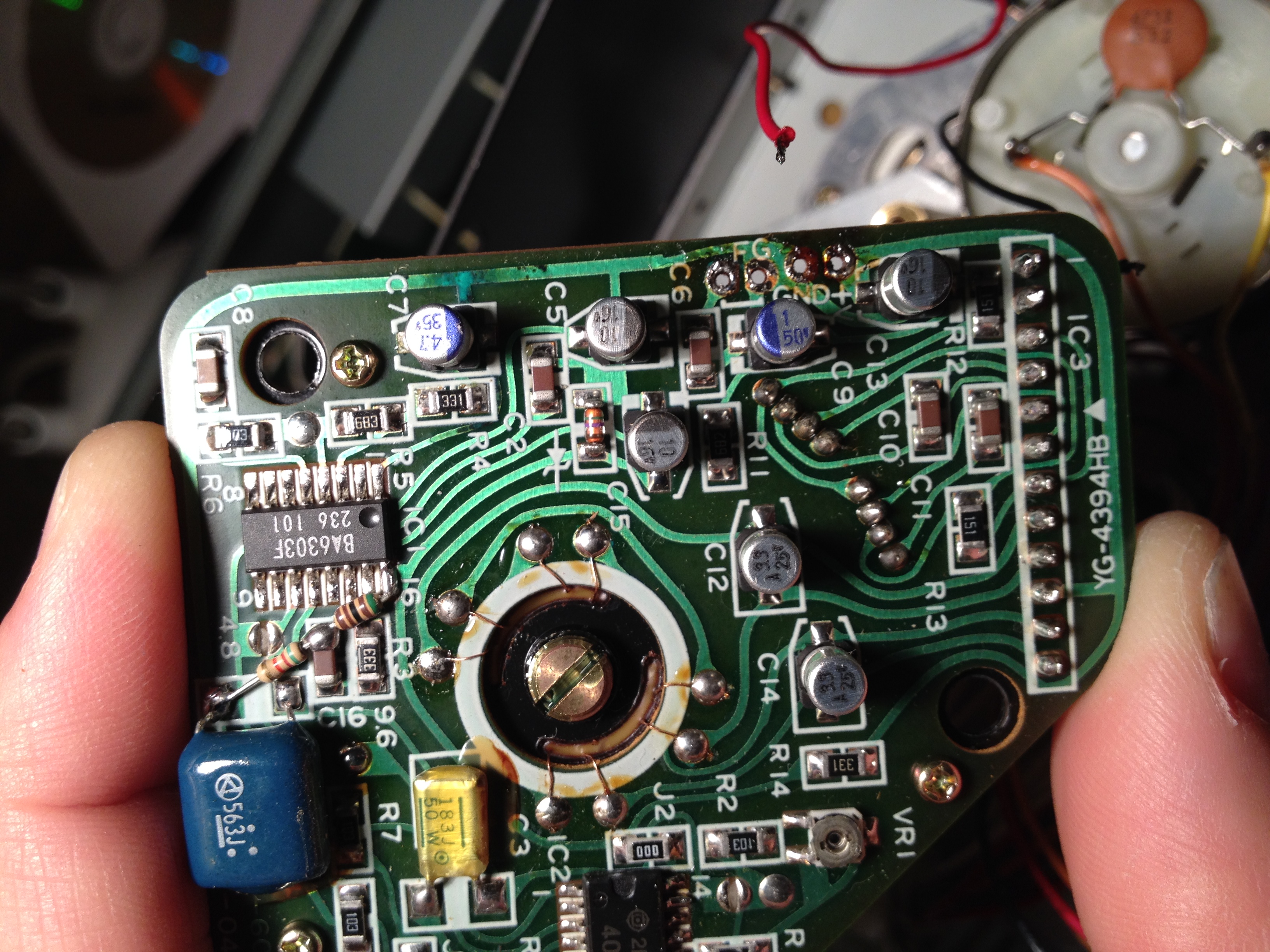

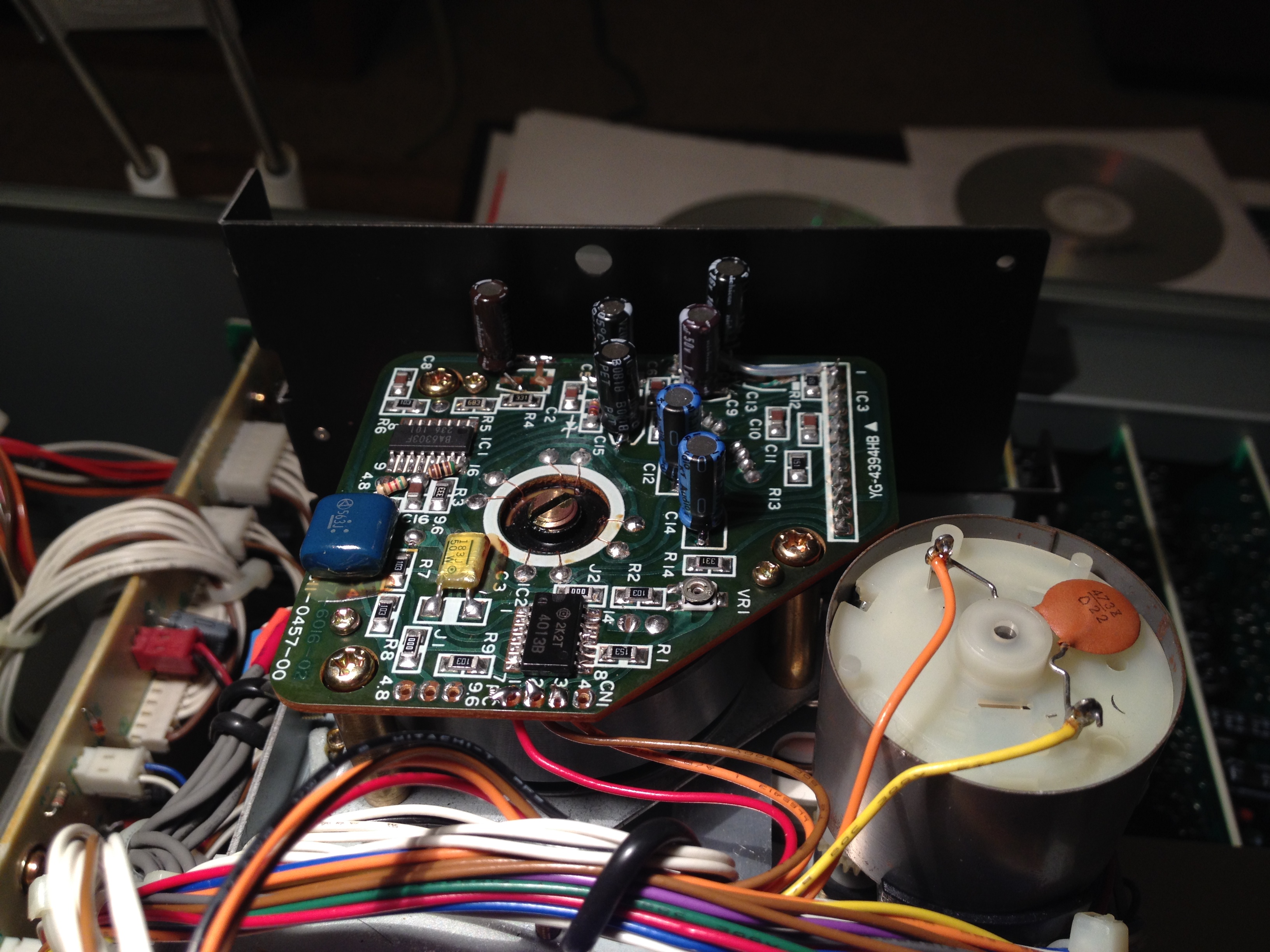

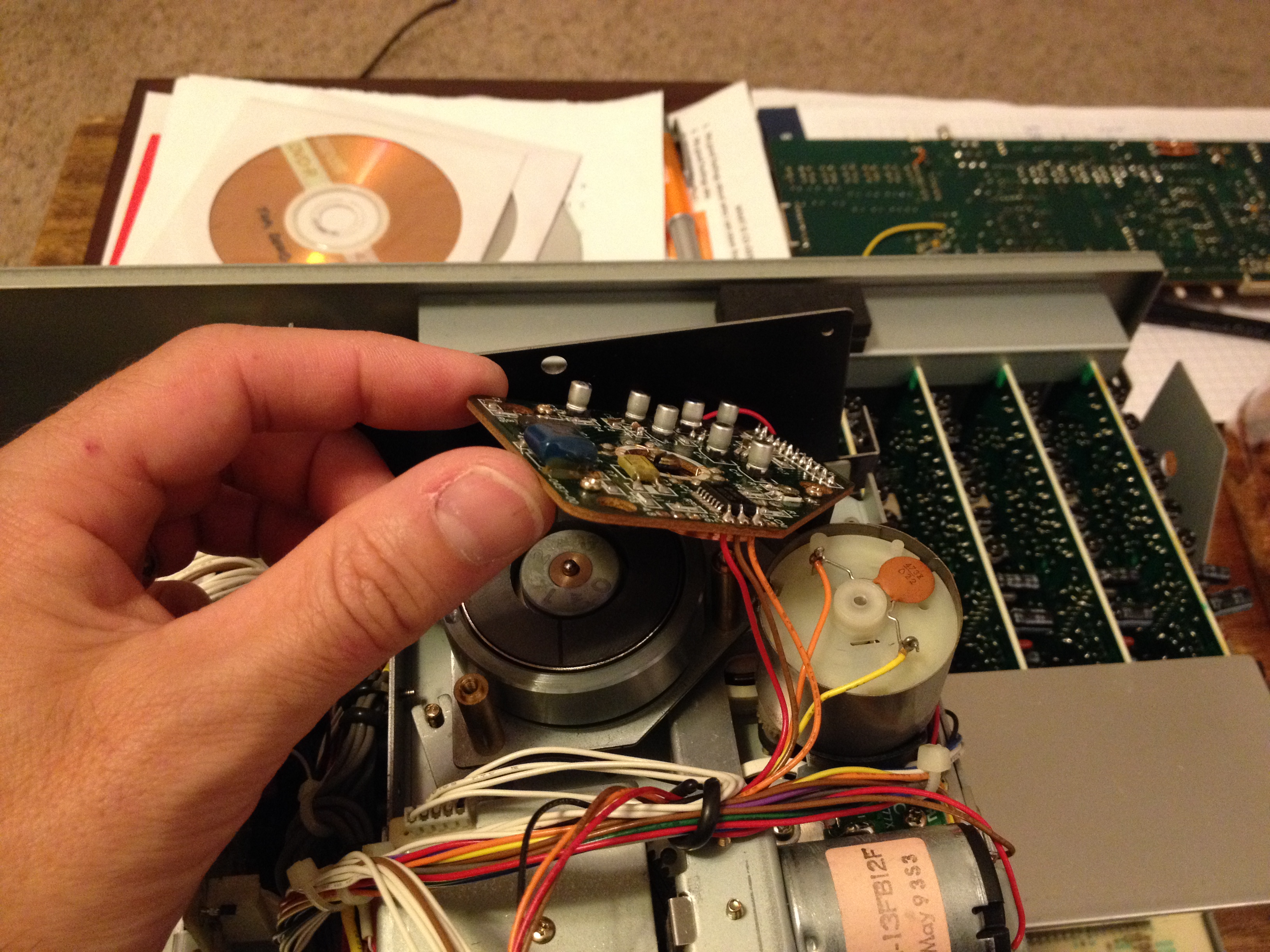

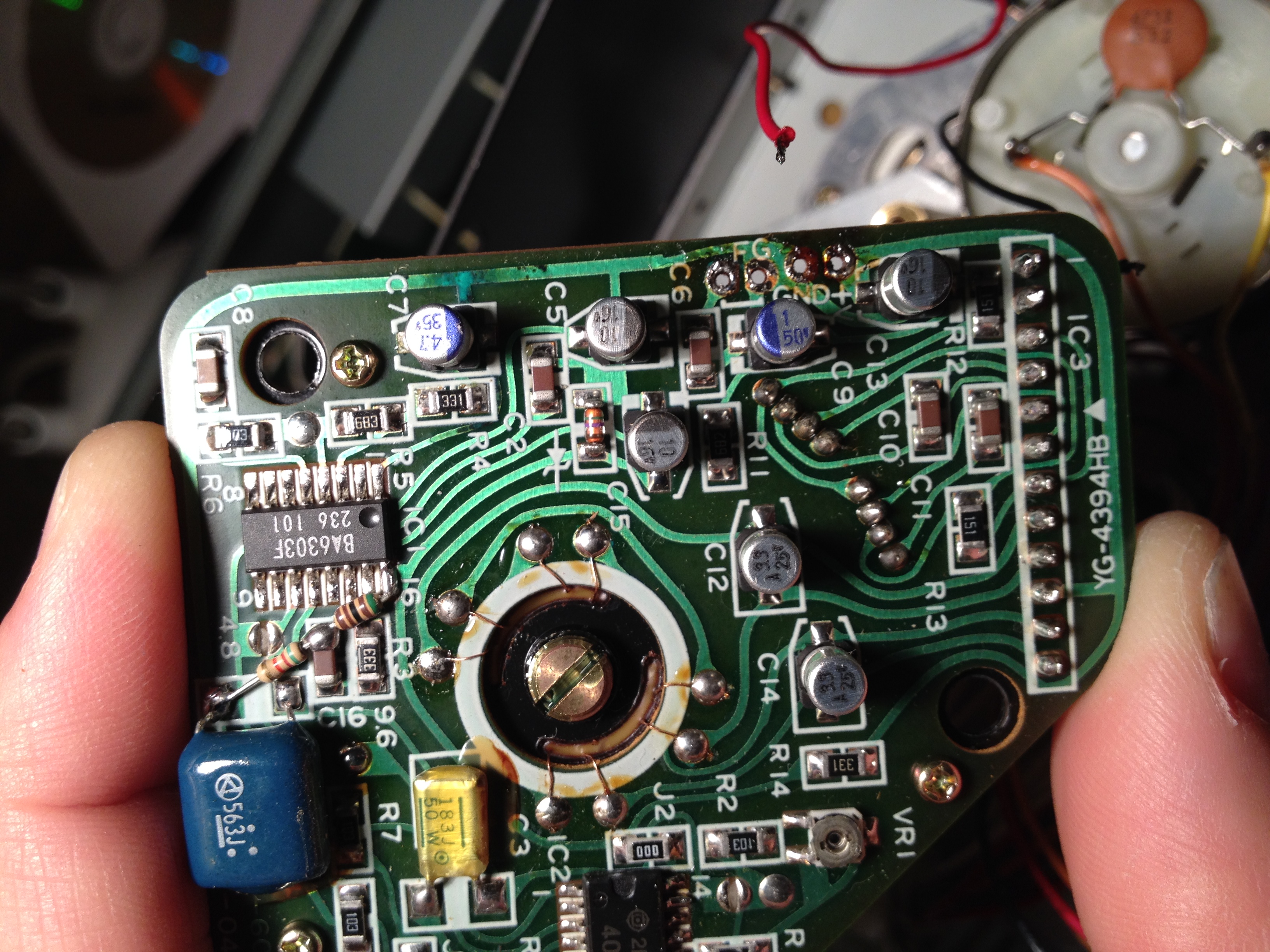

Here's the capstan servo board on the back of the capstan motor...see the little silver cans? Those are the little surface-mount electrolytic caps:

surface-mount electrolytic caps:

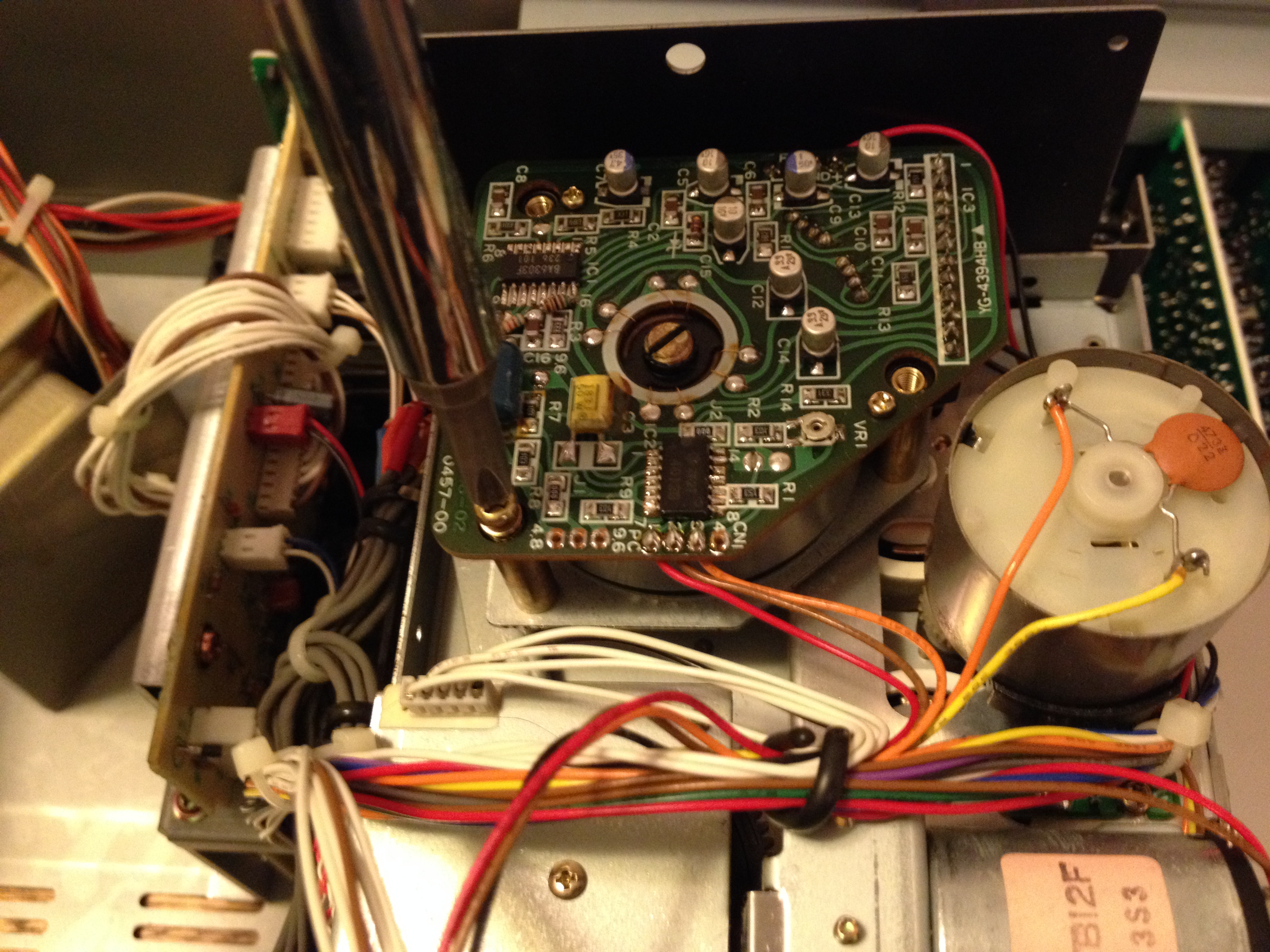

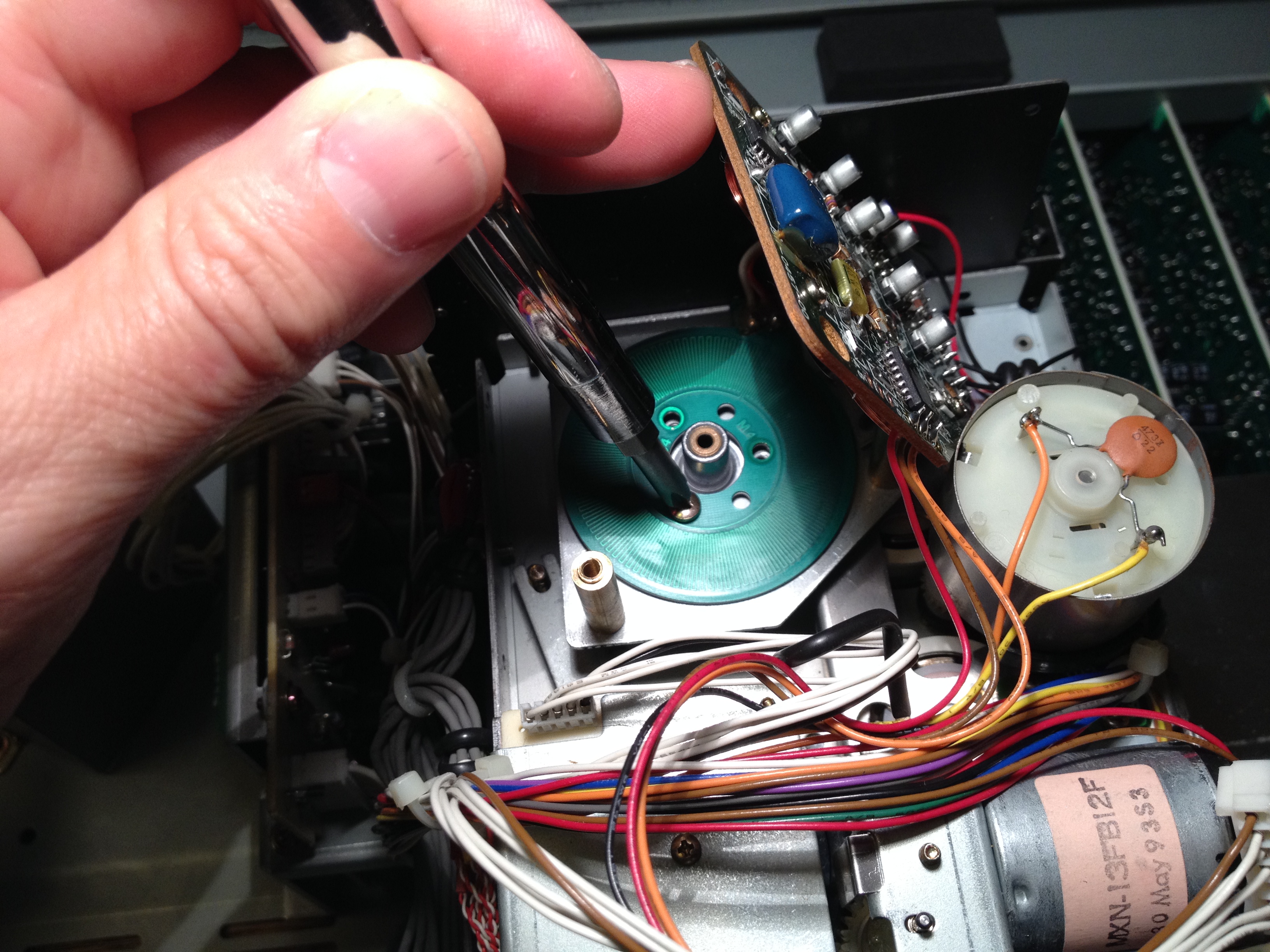

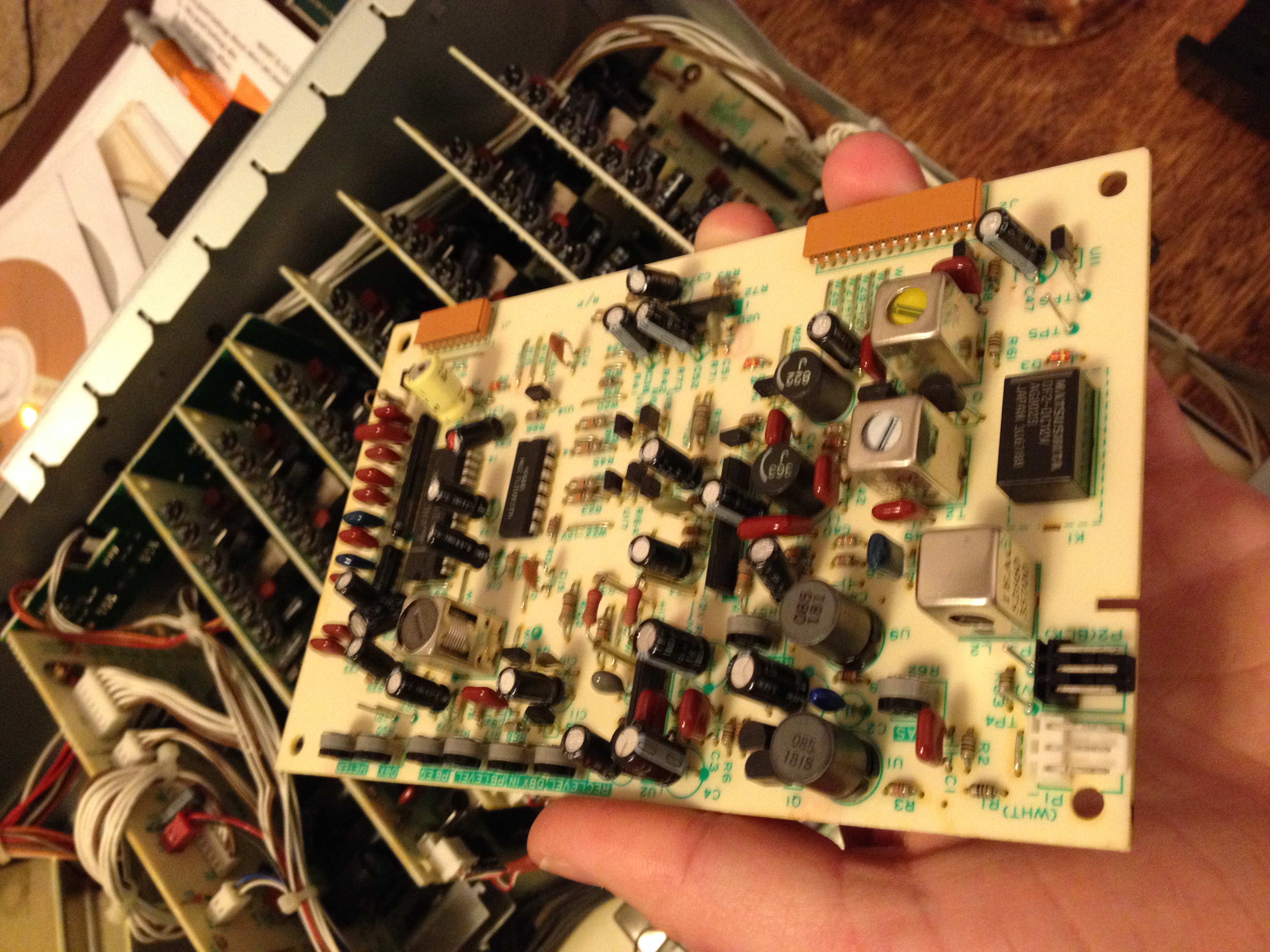

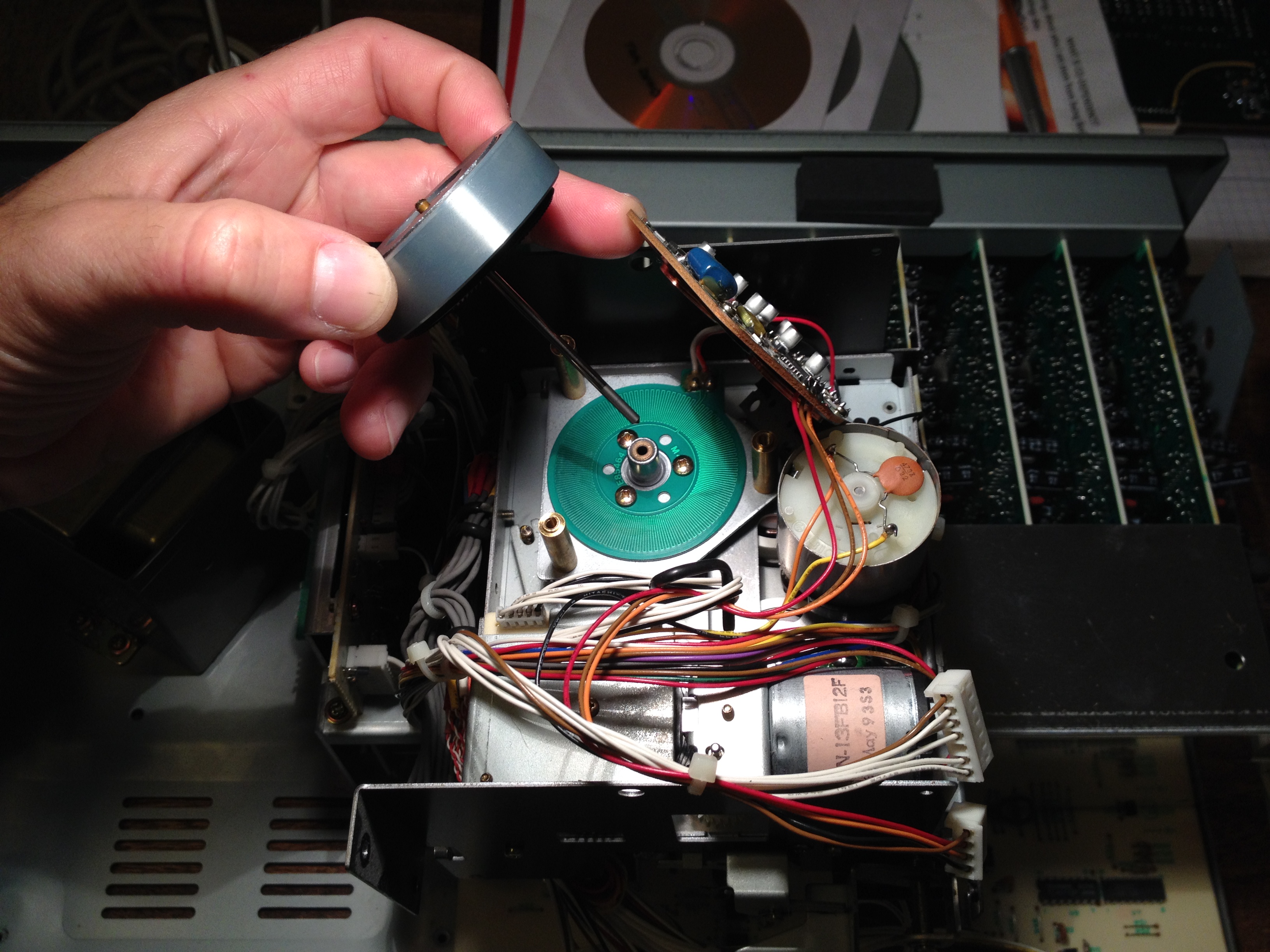

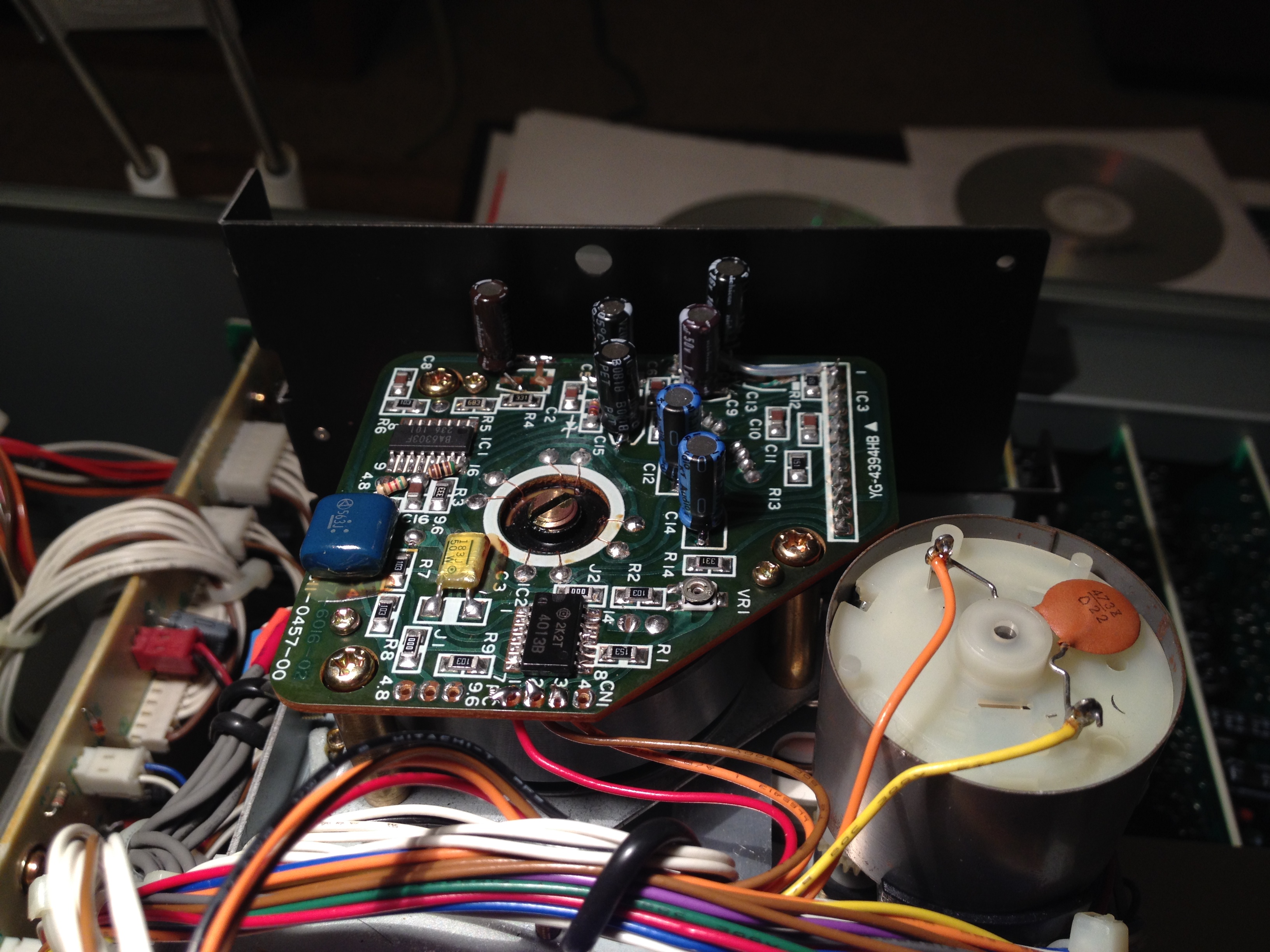

Remove some screws and the board comes off the motor assembly:

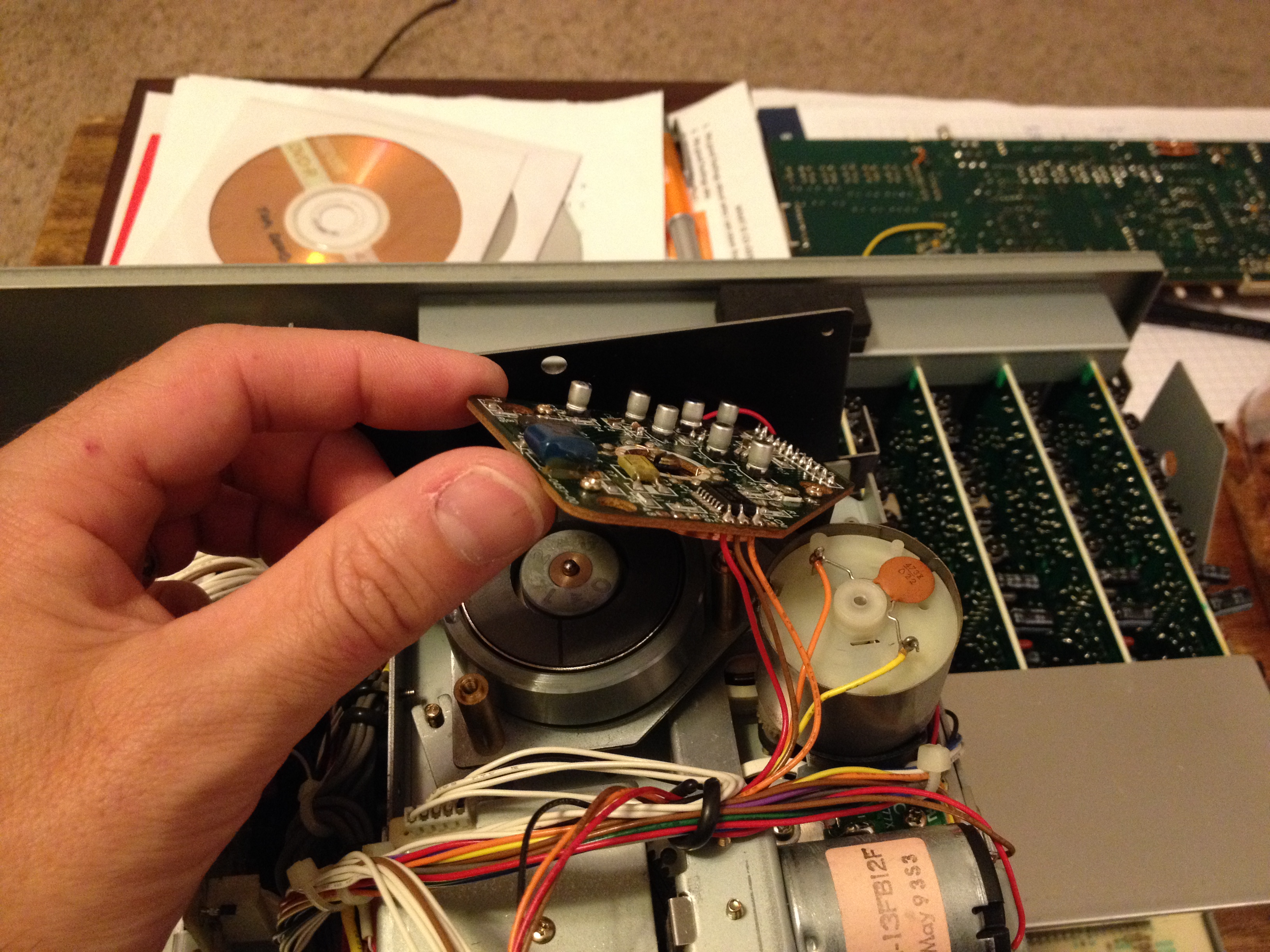

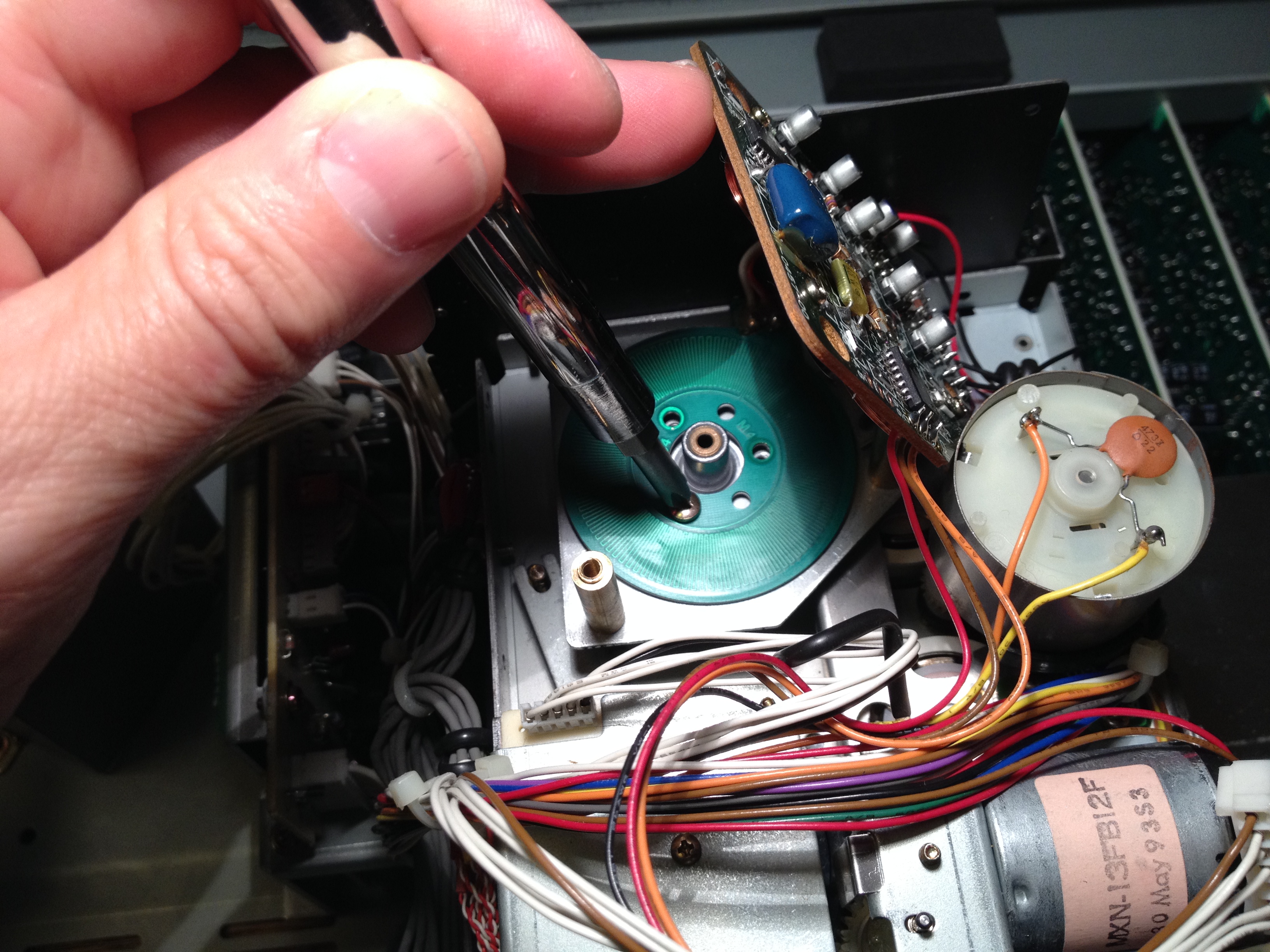

Then if you're really curious you can slide the capstan shaft with flywheel out of its bushing. Not surprisingly the construction ideology of this part of the guts is similar to the 388 (since, if I'm not mistaken, the two were somewhat contemporary to each other, the 388 being introduced first). I was careful. Its a capstan for a compact cassette machine. Its small. I didn't really want to tweak it:

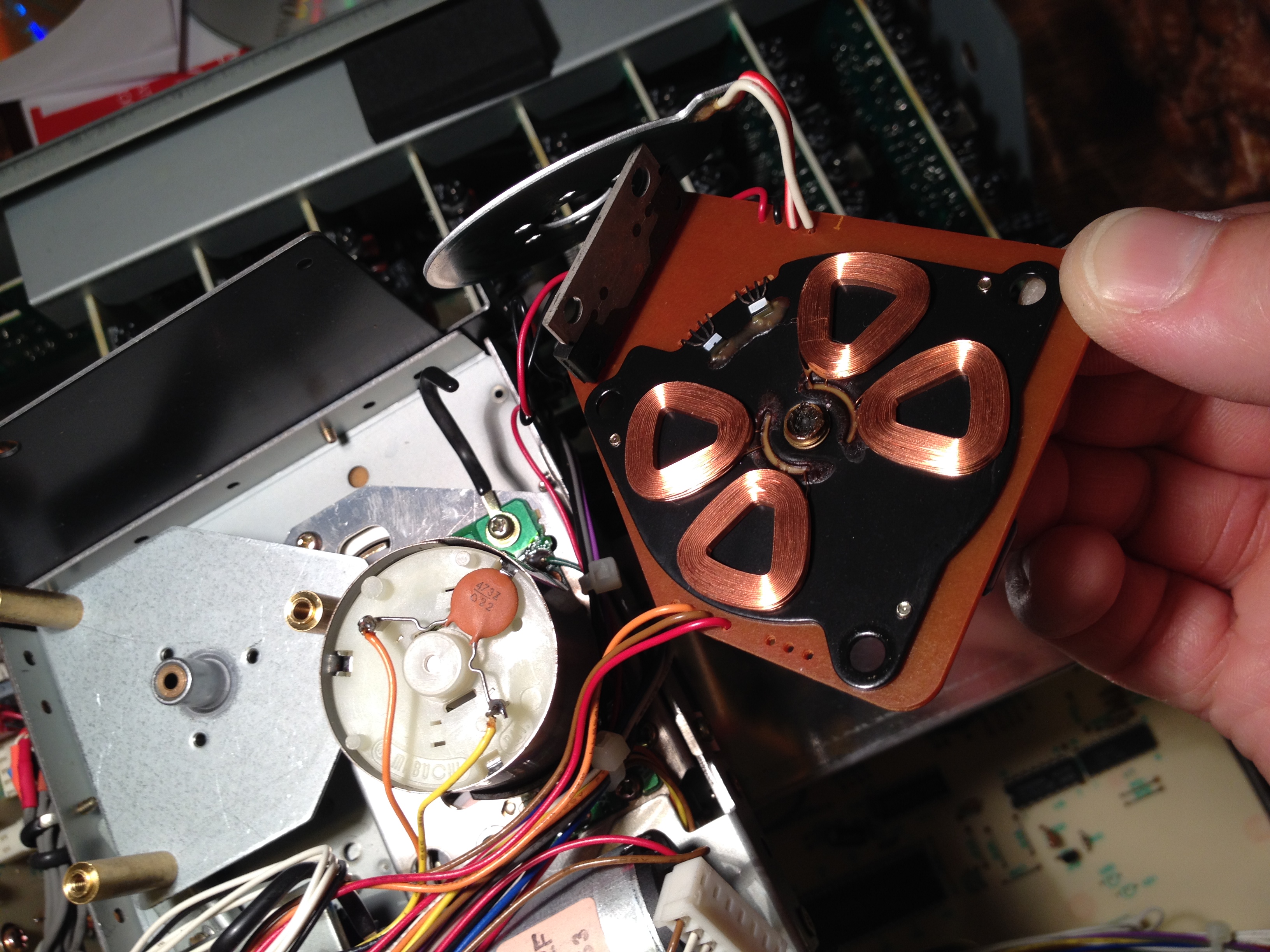

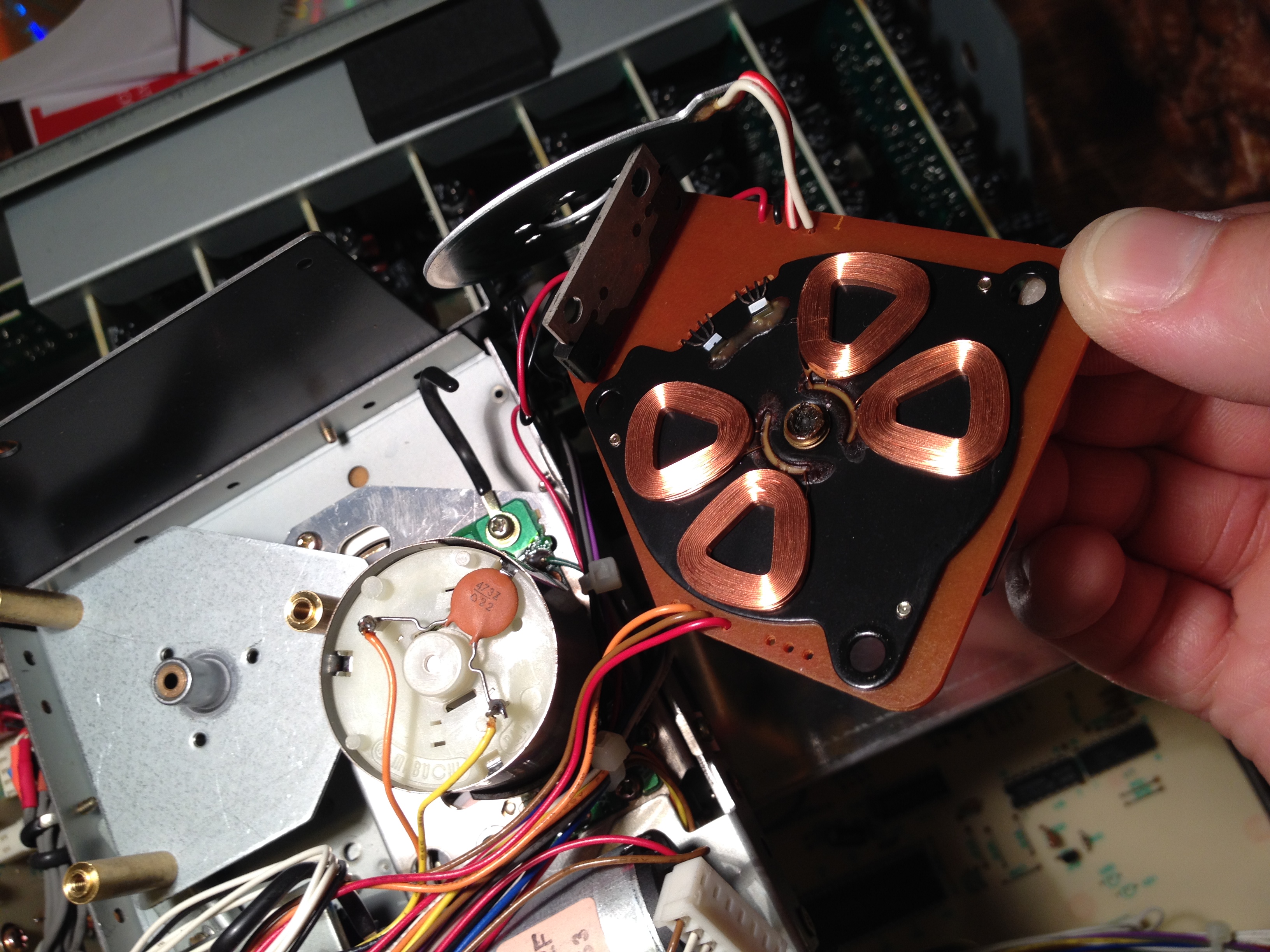

Then I really wanted to see the coils and stuff so I kept pulling stuff apart...pretty neat:

Okay...so anyway, enough with the distractions I thought...you little are mine!

are mine!

You know, I don't really remember how long it took me to do the recap...most of them went fine once I got the hang of it, but a couple of them, well...the traces leading from the solder lands acted like a quick-blow fuse you'd see in a Looney Tunes cartoon, so I had to jumper those and whatnot...but at the end of it I was pretty proud...not of my work...it was ugly...but I survived, and I learned something: I hate little surface mount electrolytics. Wait...I said that already...

hate little surface mount electrolytics. Wait...I said that already...

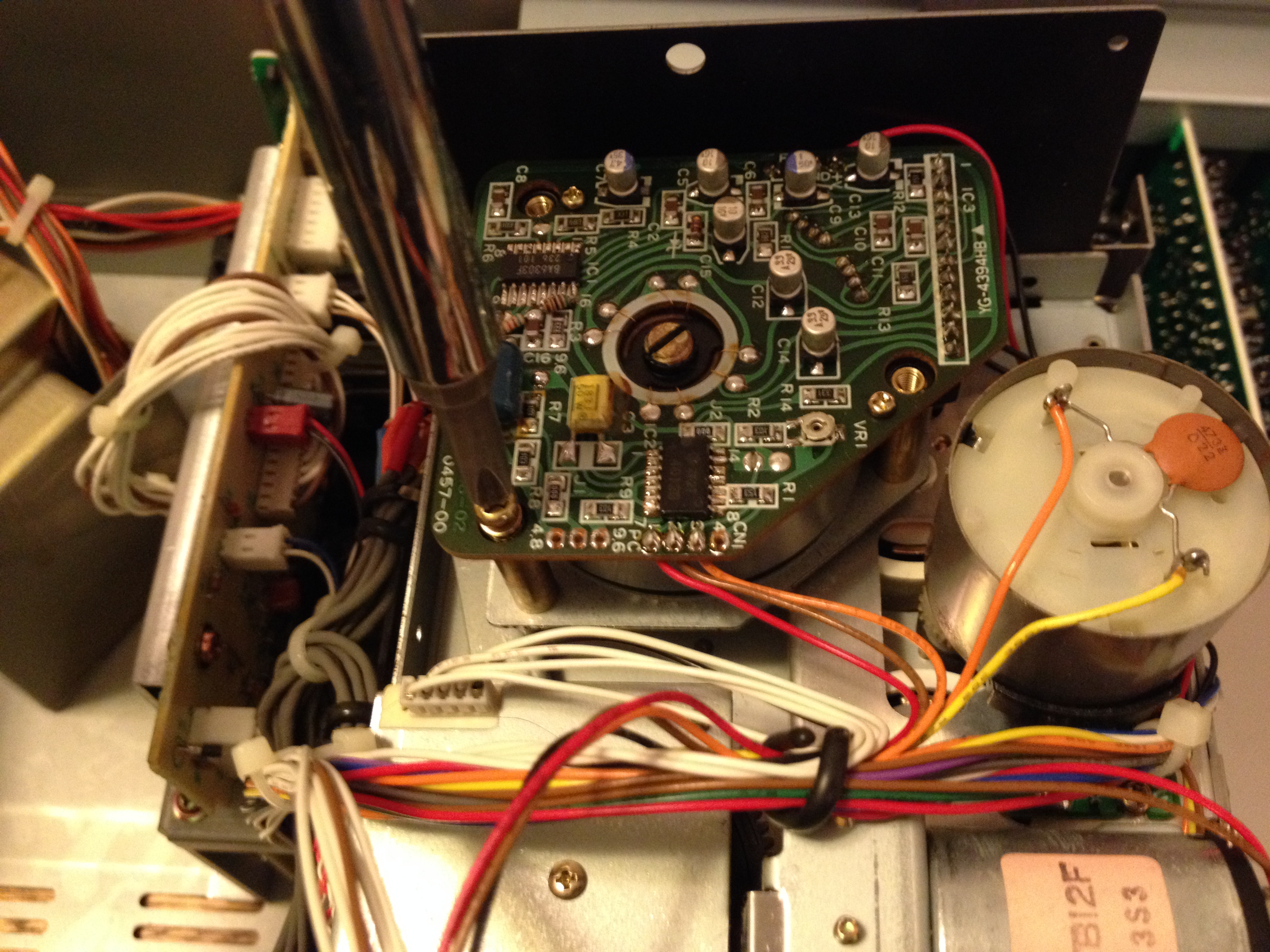

All reassembled:

$150 fully-functional 238 here I come!!

Wait...[he mutters upon powering the now offending device]...why does it still sound like a jet engine?

Next day I ordered a new capstan motor assembly direct from Teac in Montebello, CA. It was, I think, $107. Brand-new, arrived in less than a week...well worth the price of not having to touch my iron to the Looney Tunes PCB again.

That was many moons ago...haven't found the time to put the new motor in or anything. The 238 was in a box out in the shop, now its *somewhere* in storage. Someday it will come out and I'll update this thread, though I did recently pick up an accessory for the 238...

[that was a teaser...]

This "Story..." is a little different because I swear I wrote this up already, and some other forum members recall it too...unless they really just don't know what to do about my apparent dementia...but I can't find the thread anywhere, so you all get to enjoy this one.

So, anyway, the origins of this "Story..." starts here:

https://homerecording.com/bbs/gener...d-gear/oooooo-whats-da-box-372706/?highlight=

Shortly after picking up the 238 locally for $150 with a functional MMC-100 and associated cabling, I dove in to repair the capstan servo board. You see this 238 was going for relatively cheap because it had the dreaded "jet-engine" runaway capstan. This problem has been fairly well documented on the internet, and it seems the typical solution is a replacement of the electrolytic capacitors on the servo board (which is an integrated assembly to the capstan motor itself). The original caps are little surface mount parts. I hate surface-mount parts. There are also two film caps, but I figured those little

surface-mount electrolytic caps had to be the problem...and this is partly because I already had the replacement parts on-hand which = really cheap fix, oh boy, fully-functional 238 for $150 including an antiquated piece of MMC hardware I'll never use.

surface-mount electrolytic caps had to be the problem...and this is partly because I already had the replacement parts on-hand which = really cheap fix, oh boy, fully-functional 238 for $150 including an antiquated piece of MMC hardware I'll never use.Before I dive in to the "238 exposed" pictures I will say overall I was pleased when I met the seller to pick up the 238...all there including the sometimes missing or never mounted rack ears, a couple scuffs and scratches, but overall clean and complete, for example:

Having owned and done quite a bit of work on a 234, I was really surprised/impressed at how clean the interior of the chassis is on a 238...I mean, its really got a lot of room to work compared to the 4-track 234, and I love how the amp cards are plug-in on the 238, one card per channel with the input, output, record, and playback amps as well as the noise reduction all on the single card.

And my goodness...literally, after removing a structural cross-member, remove two screws, remove the cassette bay door, and the entire transport assembly is ready to unplug (a few connectors) and remove:

Here's the capstan servo board on the back of the capstan motor...see the little silver cans? Those are the little

surface-mount electrolytic caps:

surface-mount electrolytic caps:

Remove some screws and the board comes off the motor assembly:

Then if you're really curious you can slide the capstan shaft with flywheel out of its bushing. Not surprisingly the construction ideology of this part of the guts is similar to the 388 (since, if I'm not mistaken, the two were somewhat contemporary to each other, the 388 being introduced first). I was careful. Its a capstan for a compact cassette machine. Its small. I didn't really want to tweak it:

Then I really wanted to see the coils and stuff so I kept pulling stuff apart...pretty neat:

Okay...so anyway, enough with the distractions I thought...you little

are mine!

are mine!

You know, I don't really remember how long it took me to do the recap...most of them went fine once I got the hang of it, but a couple of them, well...the traces leading from the solder lands acted like a quick-blow fuse you'd see in a Looney Tunes cartoon, so I had to jumper those and whatnot...but at the end of it I was pretty proud...not of my work...it was ugly...but I survived, and I learned something: I

hate little surface mount electrolytics. Wait...I said that already...

hate little surface mount electrolytics. Wait...I said that already...All reassembled:

$150 fully-functional 238 here I come!!

Wait...[he mutters upon powering the now offending device]...why does it still sound like a jet engine?

Next day I ordered a new capstan motor assembly direct from Teac in Montebello, CA. It was, I think, $107. Brand-new, arrived in less than a week...well worth the price of not having to touch my iron to the Looney Tunes PCB again.

That was many moons ago...haven't found the time to put the new motor in or anything. The 238 was in a box out in the shop, now its *somewhere* in storage. Someday it will come out and I'll update this thread, though I did recently pick up an accessory for the 238...

[that was a teaser...]

Last edited: