timkroeger

Custom Title User

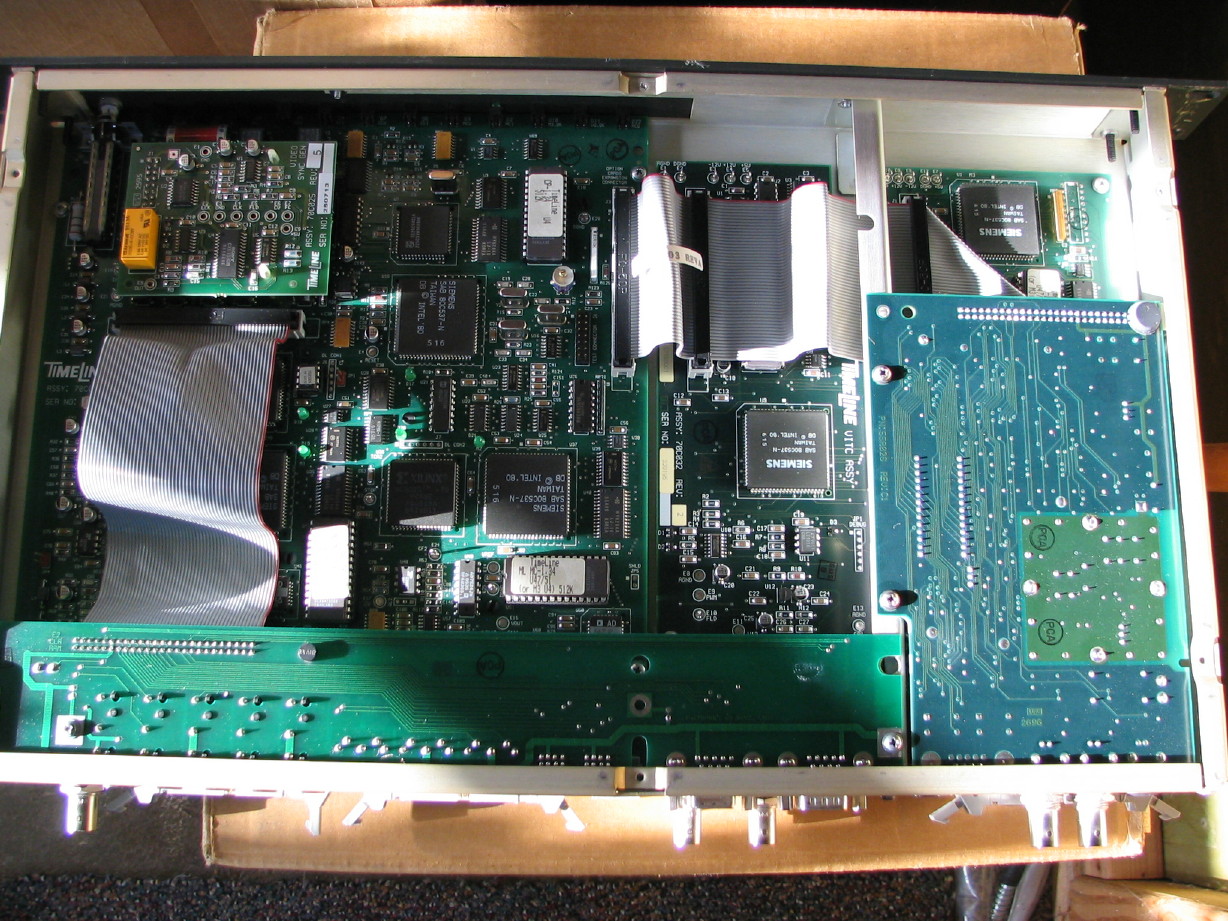

The Timeline Micro Lynx is an awesome unit for synchronizing various recording gear, both analog and digital by means of MTC (midi time code), SMPTE, word clock and what not. In order for it to control a tape recorder you need a specific transport cable that connects the micro lynx to an "accessory" port of the tape deck. Too bad the company is out of business since I think 2002, so there is basically no way of acquiring a cable except facbricating one yourself. Maybe you can contact Bill McMeekin from T/L Services, who continues to service those units and helps with parts and even suppies refurbished units. There exist a lot of different cable configurations and you can find the PDFs on the Timeline archives along with the manual of the micro lynx.

The cable consists of a 40 Pin rectangular socket housing that is connected to the micro lynx and a suitable cable with a matching connector for the tape machine. What connector to use and how many connections/conductors you need depends on the type of tape deck. The Tascam ATR-60 for example needs an 38 pin ELCO connector with only 20 conductors live, whereas the Tascam BR-20T needs a 37 pin D-Sub connector.

What I thought to be easy in fabricating the cable turned out to be quite challenging, and that is finding a matching crimp type 40 pin rectangular connector housing featuring 2 rows with 20 pins each and a nice shell casing. The original connector is manufactured by JAE and consists of 3 parts.

You can have a look at the drawings in PDF format on the linked product pages above.

Typical 40 pin cable cutting sockets will not fit due to most of the connectors being sparsely populated, void sockets, non-matching dimensions or polarizing keys and I don't think you want to use flat ribbon cable to hookup such nice tape recorder. You can find distributors for JAE-connectors on their website and even though mouser and digi-key are official JAE distributors, none of them feature those connectors. I found what I think to be suitable replacements from Omron via mouser, by comparing the spec sheets, trying to match all the dimensions. Omron connectors feature a cool hood, too, but they weren't in stock so I just went with some semi-hoods. Those connectors are IDC types (insulation displacement) just like the ribbon cable connectors but for single wires, that means you can sparsely populate conductors just as you need them and don't have to solder those small pins. I settled for the following parts:

I would have really liked a Omron XG5S-4022 horizontal hood cover, but I don't want to wait 22 weeks See the Omron spec sheet for some cool details.

See the Omron spec sheet for some cool details.

We'll see how that turns out. I got the ELCO 38 pin connectors used and refurbished via ebay and ordered 5 meters of 20 conductor 24AWG shielded cable from my favourite local electronics supplier. I would have loved a matching multi paired cable from mouser but they were only available as 100' packages and quite expensive. Anyone know where I can find 24AWG multi paired shielded cable (10 pairs)?

I'll post some pics when the connectors arrive. Hopefully everything will fit with only minor adjustments needed. Then I'll be able to slave my Tascam ATR-60/16 to my DAW... (insert evil laugh here).

Cheers

Tim

The cable consists of a 40 Pin rectangular socket housing that is connected to the micro lynx and a suitable cable with a matching connector for the tape machine. What connector to use and how many connections/conductors you need depends on the type of tape deck. The Tascam ATR-60 for example needs an 38 pin ELCO connector with only 20 conductors live, whereas the Tascam BR-20T needs a 37 pin D-Sub connector.

What I thought to be easy in fabricating the cable turned out to be quite challenging, and that is finding a matching crimp type 40 pin rectangular connector housing featuring 2 rows with 20 pins each and a nice shell casing. The original connector is manufactured by JAE and consists of 3 parts.

You can have a look at the drawings in PDF format on the linked product pages above.

Typical 40 pin cable cutting sockets will not fit due to most of the connectors being sparsely populated, void sockets, non-matching dimensions or polarizing keys and I don't think you want to use flat ribbon cable to hookup such nice tape recorder. You can find distributors for JAE-connectors on their website and even though mouser and digi-key are official JAE distributors, none of them feature those connectors. I found what I think to be suitable replacements from Omron via mouser, by comparing the spec sheets, trying to match all the dimensions. Omron connectors feature a cool hood, too, but they weren't in stock so I just went with some semi-hoods. Those connectors are IDC types (insulation displacement) just like the ribbon cable connectors but for single wires, that means you can sparsely populate conductors just as you need them and don't have to solder those small pins. I settled for the following parts:

- socket connector XG5M-4032-N

- 2x XG5S-2001 semi cover

- XG5W-0031-N replacement pins (just to be sure)

I would have really liked a Omron XG5S-4022 horizontal hood cover, but I don't want to wait 22 weeks

See the Omron spec sheet for some cool details.

See the Omron spec sheet for some cool details.We'll see how that turns out. I got the ELCO 38 pin connectors used and refurbished via ebay and ordered 5 meters of 20 conductor 24AWG shielded cable from my favourite local electronics supplier. I would have loved a matching multi paired cable from mouser but they were only available as 100' packages and quite expensive. Anyone know where I can find 24AWG multi paired shielded cable (10 pairs)?

I'll post some pics when the connectors arrive. Hopefully everything will fit with only minor adjustments needed. Then I'll be able to slave my Tascam ATR-60/16 to my DAW... (insert evil laugh here).

Cheers

Tim

Last edited:

and in various states of care, and every single one of them just simply works. That is impressive for a device that does so much and has lots of IC logic onboard to do what it does.

and in various states of care, and every single one of them just simply works. That is impressive for a device that does so much and has lots of IC logic onboard to do what it does.