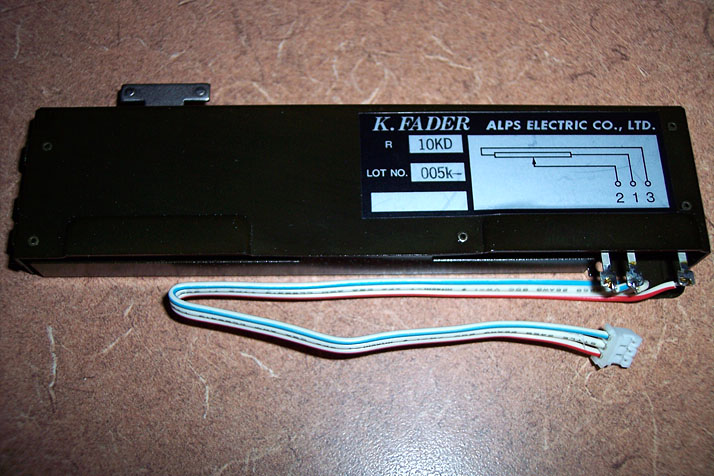

This is the ALPS K-Fader, found in

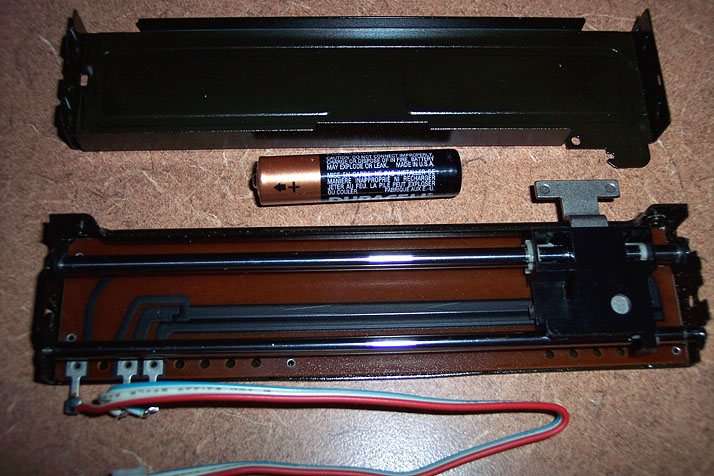

the TASCAM M-3500 console. I included an AAA battery for size comparison, they are 100mm throw faders. As you can see, they just pop open, and snap back together. There are built-in clips on the ends that make it possible.

Don't view the TASCAM/Caig info as contradictory. I'm sure the Caig Fader Lube is the right choice for *some* faders...but not for the ALPS K-Fader...which is dry-as-a-bone even when purchased new (I know). The TASCAM tech I spoke with was clear to point out that any type of lubricant would only gunk up the K-Fader, and Caig agreed, saying that particular fader (and some others) are supposed to be dry, and that their Fader Lube would be the wrong product for it.

So...it's important to find out what YOUR particular fader requires --- a lubricant cleaner or a dry cleaner. If the virgin fader appears 100% dry when first opened, I would not use the lubricant cleaner on them…IMHO. As TASCAM/Caig said...the dry-style faders will appear to be fine at first if you do use the Fader Lube on them, but will only fail/gunk-up that much sooner afterwards. I went their suggestions.

The D100 was the cleaner of choice for the K-Fader, and quite honestly, having used D100 for several years, I think it's possibly the best pure cleaner (no solvent).

If you get the D100, I recommend the small non-spray bottle, and then just apply it with a small brush or Q-Tip (I think some bottles come with a brush).

The pump-spray version doesn't always spray well…sometimes you have to pump it several times to get one burst until it’s primed…and then if you don’t spray again for a few minutes…you have repeat the priming.

:

:

).

).