Got it...

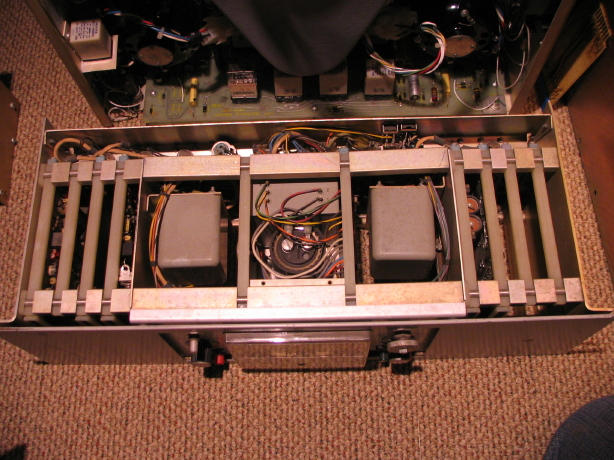

Its in really good shape considering its age. The headblock is a bit funky, but its functional and the rest of the machine is complete and uncannily clean. And...it is indeed an M-64, so I have a good machine and I can use the original one I got as a parts machine. I don't know if the one I just got is 15/30 or 7.5/15 but I'll find out soon enough. The pinch rollers look healthy...its just a good solid machine. And the electronics are what I suspected: 1 is original to the machine (i.e. M-64 standard issue) and the other two purchased later by the seller are M-23. They are very similar and either will work with the transport. All the modules have all the cards and ALL the cards look strangely un-messed-with. That means there may be some work to do on them (or maybe not) but for SURE I'm not dealing with somebody else's hacks. Same goes for the transport; it just looks...original. The electronics modules are pretty clean too especially the one original to the transport...seriously...I could take about 15 minutes to it and I bet it could be mistaken for new...its that clean. There is an uncommonly low amount of dust on all this stuff.

So it hasn't been powered up yet, but here are some more pics in no particular order. I feel the same way about this transport as I did/do my Ampex MM-1000. I suspect I will be selling my Tascam BR-20T at some point as I believe the 3M is my halftrack.

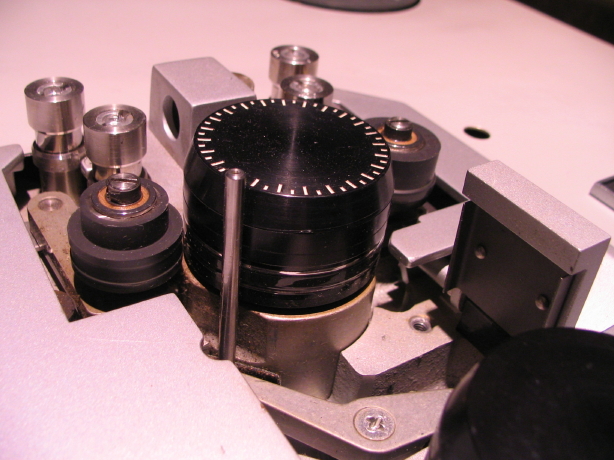

Shot of the capstan, reversing idler (peeking out), guides, pinch rollers, lifters, etc. The guides and lifters indicate low mileage:

Clean chunky buttons:

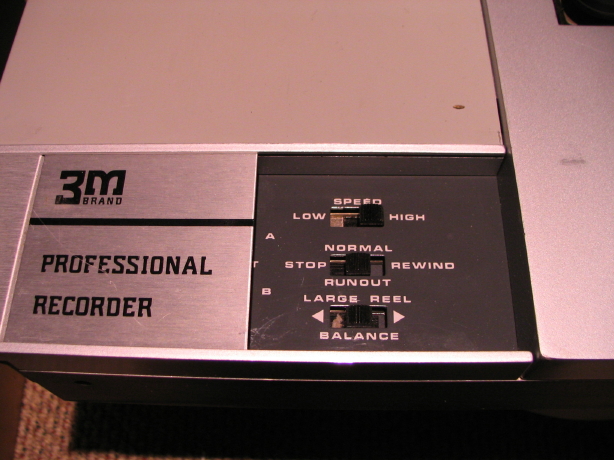

More controls...and the 3M nameplate slides over to reveal the output select and power buttons...like a safety cover:

Those aren't scratches on the control escutcheon BTW...its like grease pencil marks or something...rubs right off.

Overall shot...note that the guide/pinch roller covers are off as well as the headblock:

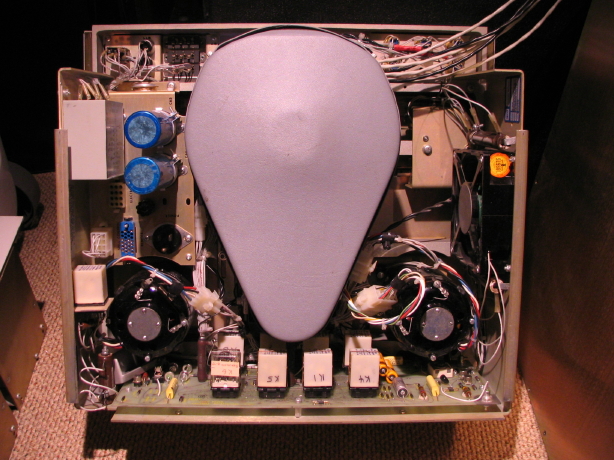

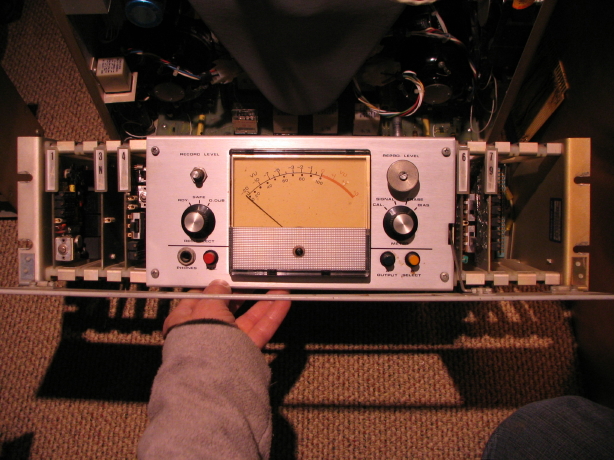

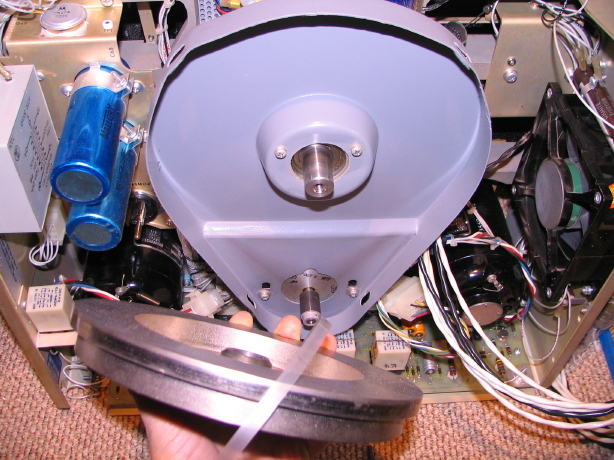

The underbelly...there is just no corrosion anywhere...and again note that there are no brakes on this thing. And that gihugic thing under the cover top center is the capstan flywheel:

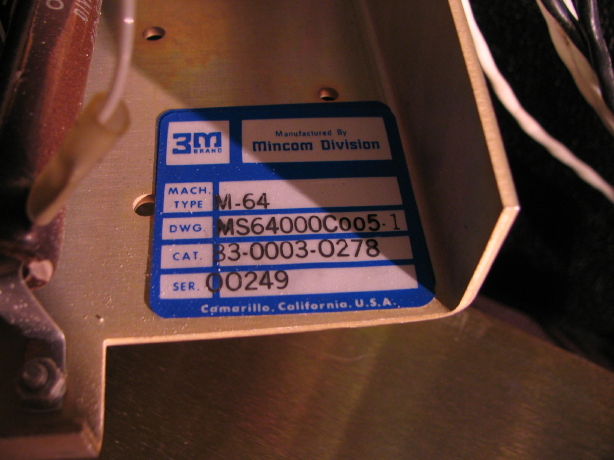

Proof of model is in the puddin':

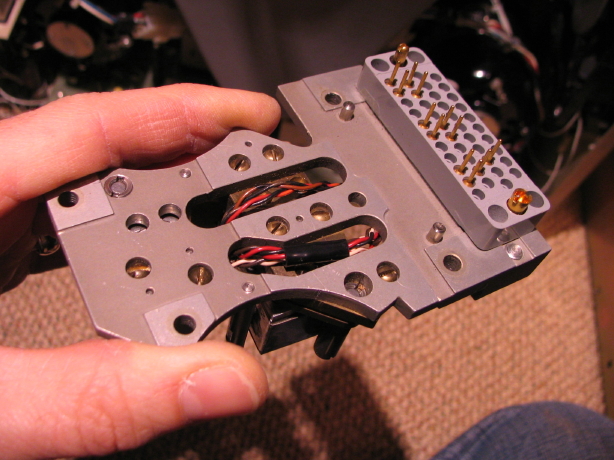

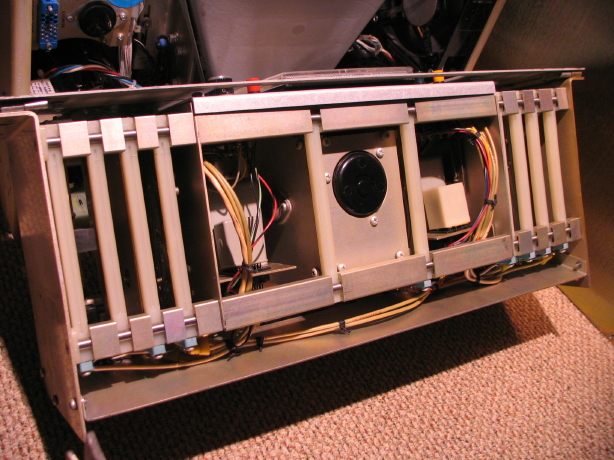

Look at how clean the transport control buttons are from the underside...and I love that thick-thick webbed transport plate casting...the epitome of overkill:

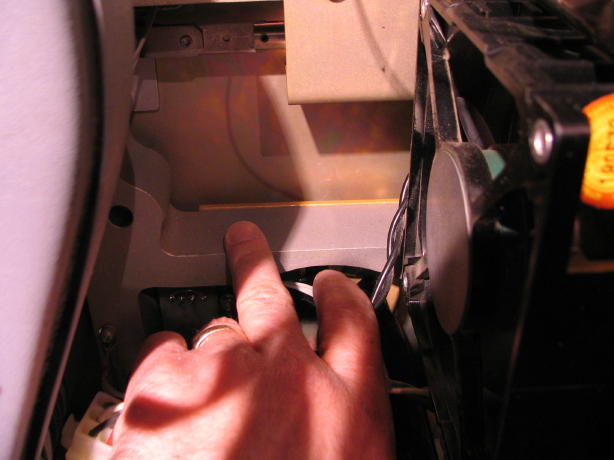

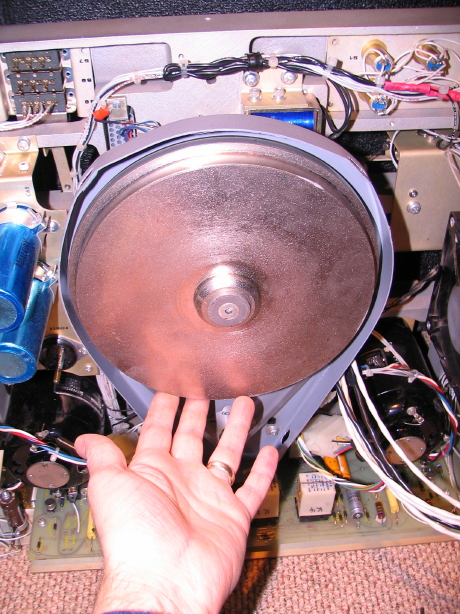

Another shot of the casting with a finger for perspective...and look at the fan...normally that thing would be caked with dust and grime:

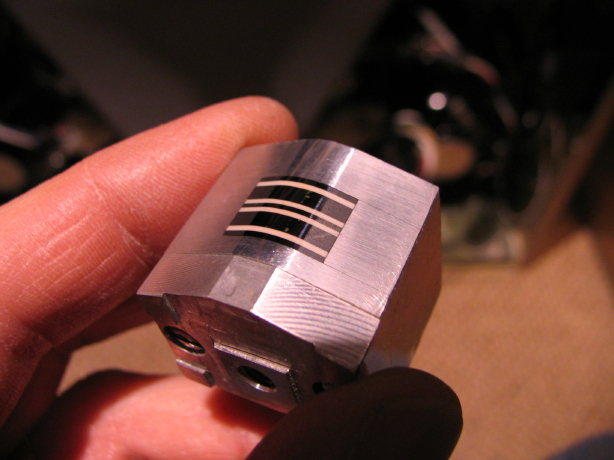

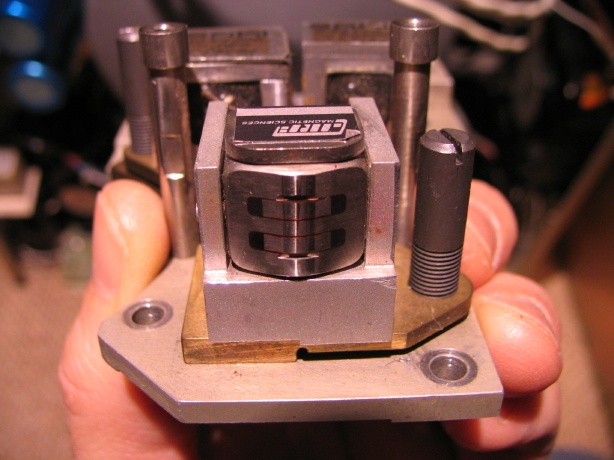

This came with it...a 2-track Saki record head. Its big. Too big to fit on the M-64 headblock...I've got a question out to the seller regarding what the story is on this thing:

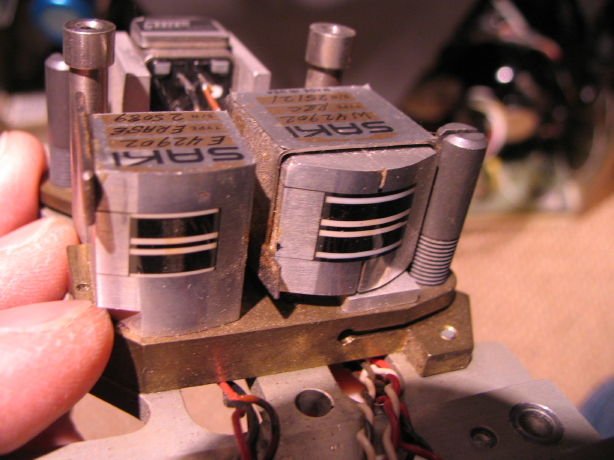

And the plug-in headblock with Saki erase and record heads and relapped Otari reproduce head. There are funky guide tabs on the erase and record heads...they look suspicious to me. Fortunately I have the stock block and heads on my other M-64 to compare. My understanding is that this block, funky as it may be, is ready to work according to John French and I'm going to trust that, but I may have the stock block lapped and setup at some point, and the repro head may be shot so I may put a Flux head there...or I may do none of that, but the options are there. Intricate block casting, precision locating pins, etc. Just a neat piece of machining:

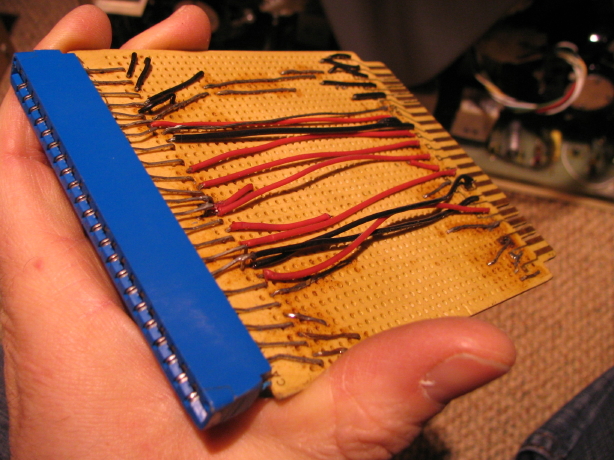

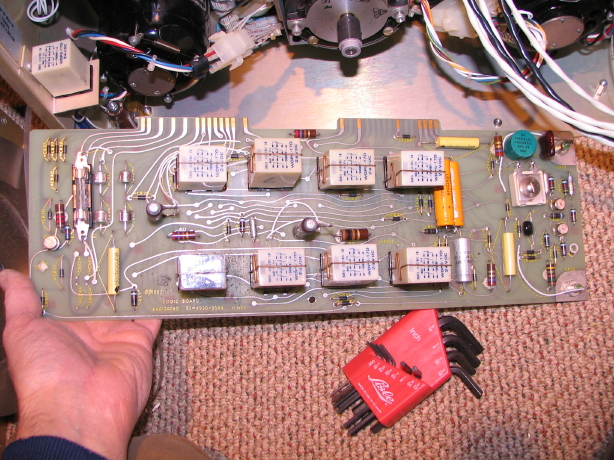

Found a homebrew extender card in one of the electronics modules...kinda scary.

That's it for now. I'll put up some pics of the electronics later.

Ofajen has been quietly touting his M-23 and the 3M machines for years now. I get it. Very well-designed and engineered. They were ahead of their time and well over-built. Sonically I imagine they are akin to the Ampex machines of the era, but with all due respect my M-64 makes a 440 transport look light-duty, which is not a slam on the 440...I had the same experience when I first laid hands on a 440 transport after working with so many Tascam machines...and that's not a slam on the Tascam machines either. Its just a different engineering standard but me likey over-built stuff so...